Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wire Brush Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

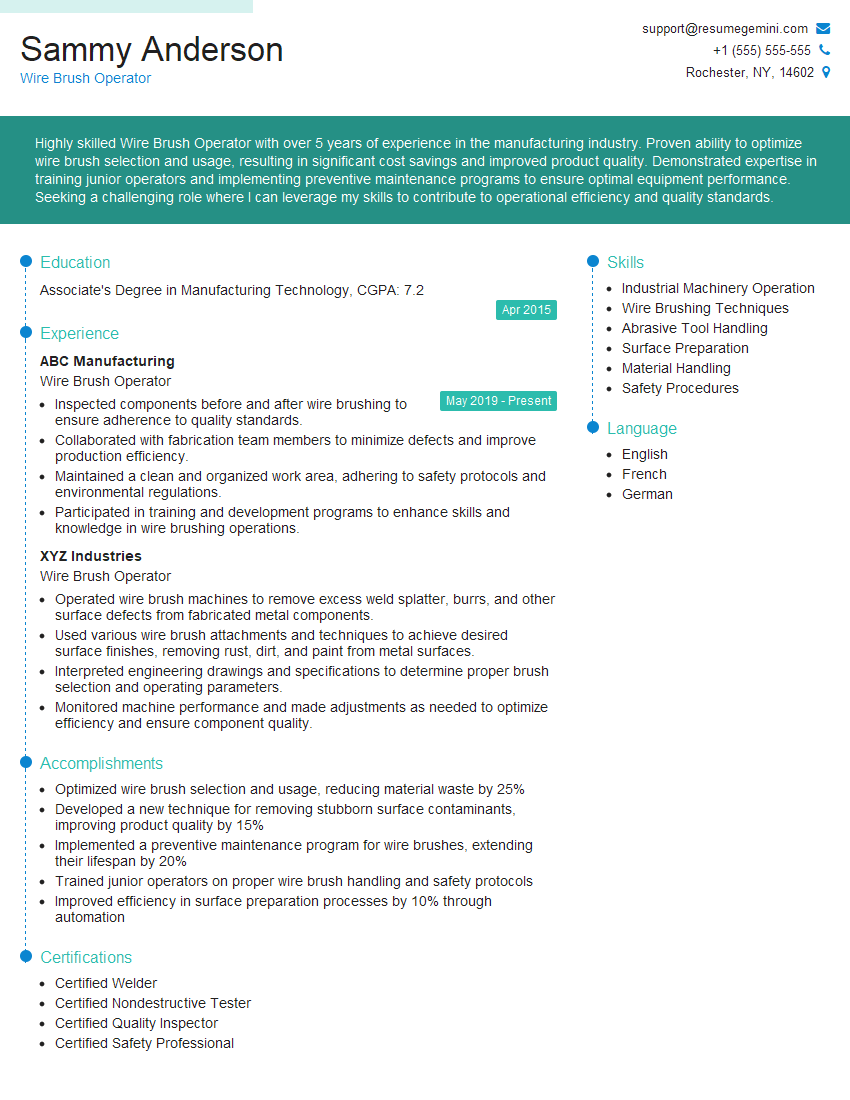

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Brush Operator

1. What are the different types of wire brushes that you are familiar with?

- Power Brushes

- Hand Brushes

2. How do you choose the right wire brush for a particular job?

Factors to Consider

- The material being brushed

- The desired surface finish

- The size and shape of the area being brushed

Types of Brushes

- Crimped wire brushes: These are general-purpose brushes that can be used on a variety of materials. They are made of crimped wire, which gives them a more aggressive action than other types of brushes.

- Knotted wire brushes: These brushes are made of knotted wire, which gives them a more gentle action than crimped wire brushes. They are ideal for delicate surfaces or for removing light rust.

- Cup brushes: These brushes are mounted on a cup-shaped backing. They are ideal for cleaning the inside of pipes and other hard-to-reach areas.

3. What are the safety precautions that you take when using a wire brush?

- Wear safety glasses to protect your eyes from flying debris.

- Wear gloves to protect your hands from abrasions.

- Use a dust mask to protect your lungs from dust and fumes.

- Be aware of the surroundings and take precautions to avoid tripping or falling.

- Never use a wire brush on electrical equipment.

4. What are some of the common applications for wire brushes?

- Cleaning metal surfaces

- Removing rust and corrosion

- Preparing surfaces for painting or welding

- Deburring metal edges

- Cleaning concrete surfaces

5. How do you maintain a wire brush?

- Clean the brush regularly with a wire brush cleaner or a solvent.

- Inspect the brush for any damaged or loose wires and replace them as necessary.

- Store the brush in a dry place to prevent rust.

6. What are the different types of materials that can be brushed with a wire brush?

- Metals

- Plastics

- Wood

- Concrete

7. What are the different grades of wire brushes?

- Soft

- Medium

- Hard

8. What are the different sizes of wire brushes?

- Small

- Medium

- Large

9. What are the different shapes of wire brushes?

- Round

- Square

- Rectangular

10. What are the different types of wire brush handles?

- Plastic

- Wood

- Metal

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Brush Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Brush Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire Brush Operators play a pivotal role in manufacturing and fabrication industries. Their primary responsibility involves using wire brushes to clean and polish metal surfaces. They ensure the removal of rust, dirt, and other contaminants to prepare surfaces for further processing or assembly.

1. Surface Preparation

Wire Brush Operators skillfully operate wire brushing machines to remove rust, scale, corrosion, and other contaminants from metal surfaces.

- Selecting appropriate wire brushes based on surface condition and desired finish.

- Adjusting machine settings to achieve optimal brushing pressure and speed.

- Thoroughly cleaning surfaces to ensure proper adhesion of coatings or finishes.

2. Deburring and Polishing

Wire Brush Operators utilize wire brushes to remove burrs and sharp edges from metal parts.

- Using various brush types and techniques to achieve desired surface smoothness.

- Polishing surfaces to enhance appearance and functionality.

- Ensuring precise and consistent finishing results.

3. Equipment Maintenance and Safety

Wire Brush Operators are responsible for maintaining and inspecting wire brushing equipment.

- Performing regular cleaning and lubrication of machines.

- Identifying and replacing worn or damaged parts.

- Following safety protocols and wearing appropriate personal protective equipment.

4. Production Monitoring and Quality Control

Wire Brush Operators monitor production processes and ensure quality standards.

- Verifying surface finish and cleanliness according to specifications.

- Maintaining production logs and reporting any deviations or issues.

- Collaborating with other team members to resolve production challenges.

Interview Preparation Tips

To ace your Wire Brush Operator interview, consider the following preparation tips and hacks:

1. Research the Company and Position

Thoroughly research the company, its products or services, and the specific Wire Brush Operator position. This will help you understand their business and the requirements of the role.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on the latest trends and technologies.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful, concise answers. Practice these answers to build confidence and deliver them smoothly during the interview.

- Example Outline:

- Tell me about your experience using wire brushing machines.

- How do you ensure the quality and precision of your work?

- Describe your approach to problem-solving in a production environment.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job responsibilities. Quantify your accomplishments whenever possible to provide concrete evidence of your abilities.

- Use action verbs and specific examples to describe your contributions.

- Example: “Operated wire brushing machines to clean and deburr over 100 metal parts per hour, ensuring a defect rate of less than 1%.”

4. Demonstrate Your Enthusiasm and Motivation

Conveying your enthusiasm for the role and the manufacturing industry is crucial. Highlight your passion for working with machines, attention to detail, and commitment to quality.

- Share examples of how you have gone above and beyond in previous roles.

- Express your eagerness to contribute to the company’s success and learn from experienced professionals.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wire Brush Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.