Are you gearing up for an interview for a Wire Drawer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wire Drawer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

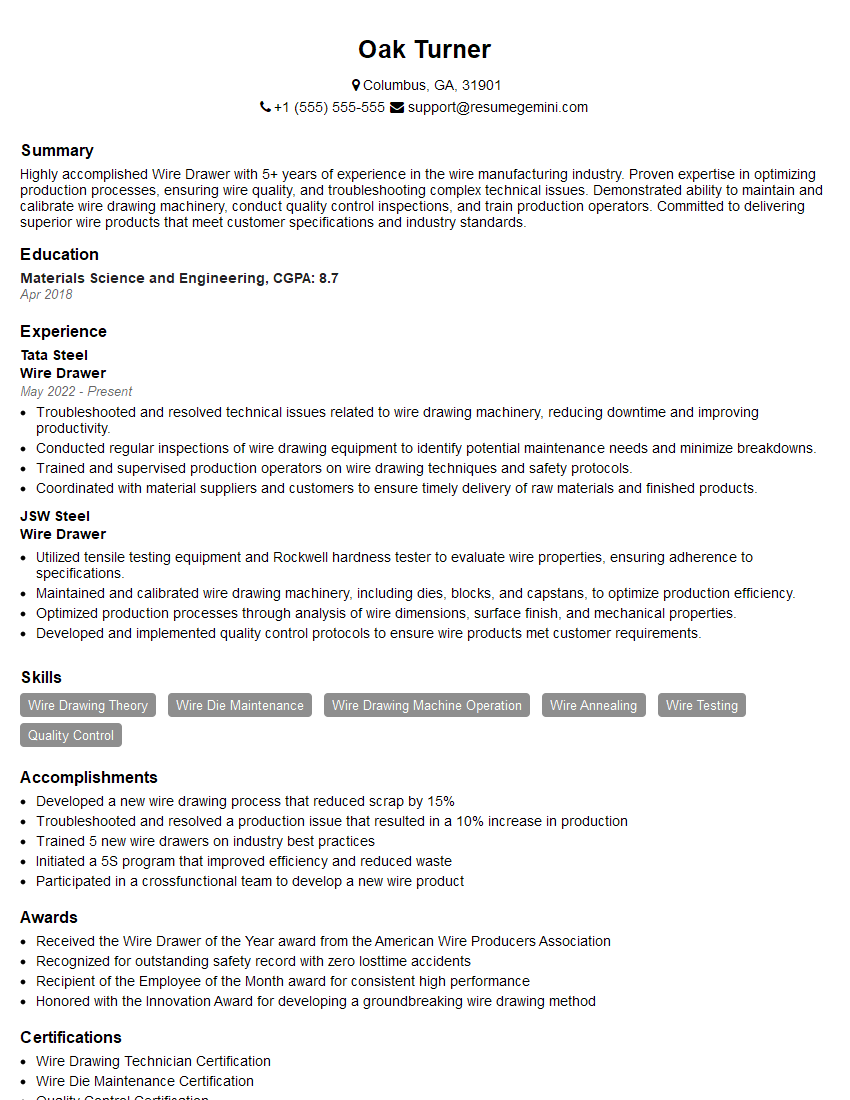

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Drawer

1. What are the different types of wire drawing dies, and what are their advantages and disadvantages?

There are four main types of wire drawing dies: natural diamond, synthetic diamond, tungsten carbide, and ceramic. Each type has its own advantages and disadvantages:

- Natural diamond dies are the most expensive, but they are also the most durable and produce the highest quality wire. They are ideal for drawing fine wire and wire with complex shapes.

- Synthetic diamond dies are less expensive than natural diamond dies, but they are not as durable. They are still capable of producing high quality wire, but they are not as well suited for drawing fine wire or wire with complex shapes.

- Tungsten carbide dies are less expensive than diamond dies, but they are also less durable. They are best suited for drawing medium to large diameter wire.

- Ceramic dies are the least expensive type of wire drawing die, but they are also the least durable. They are best suited for drawing large diameter wire.

2. What are the different factors that affect the quality of drawn wire?

Die selection

- The type of die used will have a significant impact on the quality of the drawn wire. The die should be selected based on the desired wire diameter, material, and surface finish.

Drawing speed

- The drawing speed will also affect the quality of the drawn wire. If the drawing speed is too high, the wire may be damaged or broken. If the drawing speed is too low, the wire may be annealed and lose its strength.

Lubrication

- Lubrication is essential to prevent the wire from sticking to the die and breaking. The type of lubricant used will depend on the material of the wire and the drawing process.

Annealing

- Annealing is a process of heating the wire to a high temperature and then cooling it slowly. This process softens the wire and makes it more ductile.

3. What are the different types of wire drawing machines, and what are their advantages and disadvantages?

There are two main types of wire drawing machines: bull block machines and continuous drawing machines.

- Bull block machines are used to draw wire in small batches. They are simple to operate and can be used to draw a wide variety of wire diameters and materials.

- Continuous drawing machines are used to draw wire in large batches. They are more efficient than bull block machines, but they are also more expensive and complex to operate.

4. What are the safety precautions that must be taken when operating a wire drawing machine?

There are a number of safety precautions that must be taken when operating a wire drawing machine, including:

- Always wear safety glasses and gloves when operating the machine.

- Never reach into the drawing die while the machine is running.

- Keep the work area clean and free of debris.

- Be aware of the location of the emergency stop button.

- Follow all manufacturer’s instructions for operating the machine.

5. What are the different types of wire drawing lubricants, and what are their advantages and disadvantages?

There are a number of different types of wire drawing lubricants available, including:

- Oil-based lubricants are the most common type of wire drawing lubricant. They are relatively inexpensive and easy to apply.

- Water-based lubricants are more environmentally friendly than oil-based lubricants. They are also less likely to cause staining or discoloration of the wire.

- Solid lubricants are typically used for drawing fine wire or wire with complex shapes. They are more expensive than oil-based or water-based lubricants, but they provide better lubrication.

6. What are the different types of wire drawing dies, and what are their applications?

There are a number of different types of wire drawing dies available, including:

- Diamond dies are the most common type of wire drawing die. They are made of natural or synthetic diamond and are very durable.

- Tungsten carbide dies are less expensive than diamond dies, but they are also less durable. They are best suited for drawing medium to large diameter wire.

- Ceramic dies are the least expensive type of wire drawing die, but they are also the least durable. They are best suited for drawing large diameter wire.

7. What are the different factors that affect the quality of drawn wire?

The quality of drawn wire is affected by a number of factors, including:

- The type of die used

- The drawing speed

- The lubrication

- The annealing process

8. What are the different types of wire drawing machines, and what are their advantages and disadvantages?

There are two main types of wire drawing machines: bull block machines and continuous drawing machines.

- Bull block machines are used to draw wire in small batches. They are simple to operate and can be used to draw a wide variety of wire diameters and materials.

- Continuous drawing machines are used to draw wire in large batches. They are more efficient than bull block machines, but they are also more expensive and complex to operate.

9. What are the safety precautions that must be taken when operating a wire drawing machine?

There are a number of safety precautions that must be taken when operating a wire drawing machine, including:

- Always wear safety glasses and gloves when operating the machine.

- Never reach into the drawing die while the machine is running.

- Keep the work area clean and free of debris.

- Be aware of the location of the emergency stop button.

- Follow all manufacturer’s instructions for operating the machine.

10. What are the different types of wire drawing lubricants, and what are their advantages and disadvantages?

There are a number of different types of wire drawing lubricants available, including:

- Oil-based lubricants are the most common type of wire drawing lubricant. They are relatively inexpensive and easy to apply.

- Water-based lubricants are more environmentally friendly than oil-based lubricants. They are also less likely to cause staining or discoloration of the wire.

- Solid lubricants are typically used for drawing fine wire or wire with complex shapes. They are more expensive than oil-based or water-based lubricants, but they provide better lubrication.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Drawer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Drawer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wire Drawer is responsible for operating and maintaining wire drawing machinery to produce various types of wire used in various industries.

1. Wire Drawing

Sets up and operates wire drawing machines to reduce the diameter of metal wire.

- Monitors the drawing process to ensure that the wire meets specifications.

- Inspects the finished wire for quality.

2. Equipment Maintenance

Performs routine maintenance and repairs on wire drawing machines.

- Lubricates and cleans machines.

- Replaces worn parts.

3. Quality Control

In addition, the wire drawer may also perform some quality control processes.

- Checks the quality of the incoming wire.

- Tests the finished wire to ensure that it meets specifications.

4. Other Responsibilities

In addition, a wire drawer may also be responsible for the following tasks:

- Loading and unloading wire from machines.

- Keeping the work area clean and organized.

- Following safety procedures.

Interview Tips

Preparing for an interview for a Wire Drawer position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the Company and Position

Take the time to research the company you are applying to and the specific position you are interested in. This will help you understand the company’s culture and the requirements of the job.

- Visit the company’s website to learn about its history, products, and services.

- Read online reviews of the company to get a sense of its culture and work environment.

- Talk to people you know who work at the company to get their insights on the company and the position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”.

- Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- When answering questions, be specific and provide examples of your experience and skills.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in wire drawing and related fields.

- Be prepared to discuss your experience in detail, including the types of wire you have drawn, the machines you have operated, and the quality control processes you have followed.

- If you have any relevant certifications or training, be sure to mention them.

4. Be Prepared to Answer Technical Questions

The interviewer may also ask you some technical questions about wire drawing.

- Be prepared to answer questions about the different types of wire drawing machines, the different types of wire that can be drawn, and the different quality control processes that can be used.

- If you are not sure of the answer to a question, be honest and say so.

Next Step:

Now that you’re armed with the knowledge of Wire Drawer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wire Drawer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini