Feeling lost in a sea of interview questions? Landed that dream interview for Wire Drawing Die Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wire Drawing Die Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

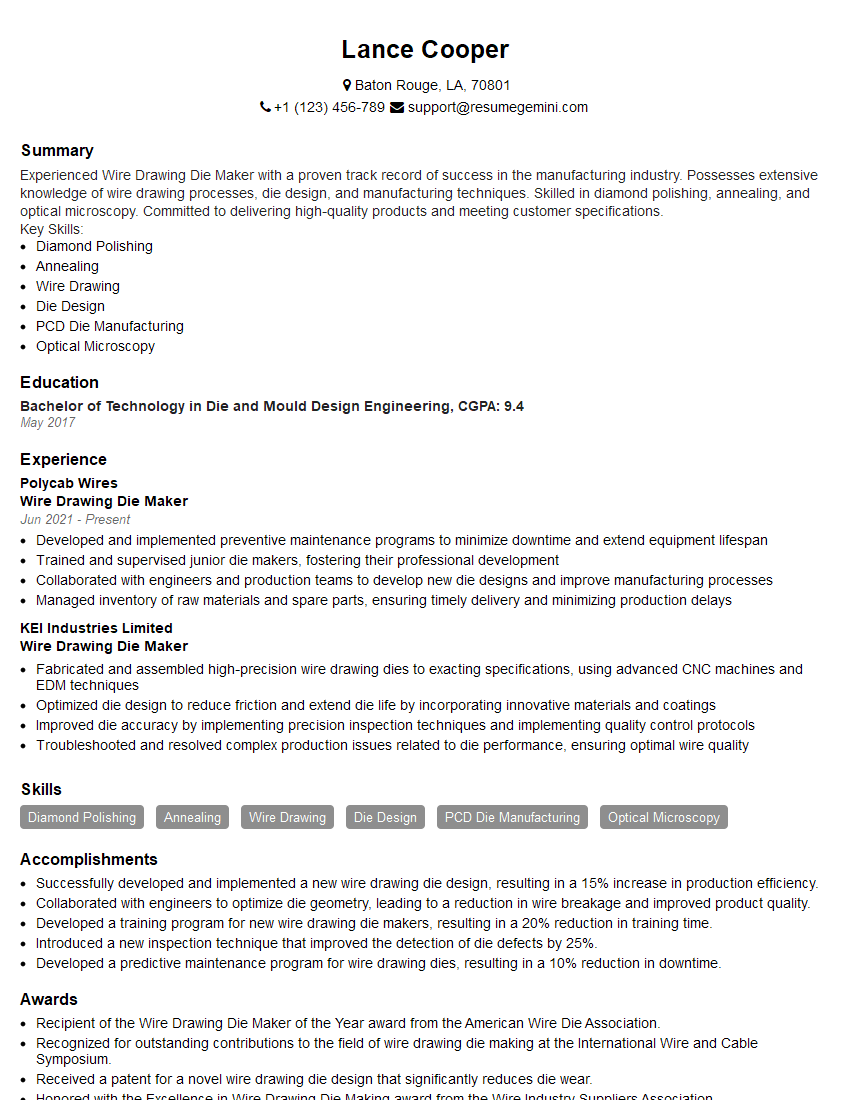

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Drawing Die Maker

1. Explain the process of wire drawing and the role of dies in it?

Wire drawing is a metalworking process used to reduce the cross-sectional area of a wire by pulling it through a series of dies.

- Dies are precision-machined tools that have a specific shape and size.

- As the wire is pulled through the die, it is reduced in diameter and elongated.

- The dies are typically made of tungsten carbide or diamond and are designed to produce a specific diameter and surface finish on the wire.

2. What are the different types of wire drawing dies and their applications?

PCD dies

- PCD (polycrystalline diamond) dies are used for drawing fine wires with diameters less than 0.2 mm.

- They are also used for drawing wires made of hard materials such as stainless steel and titanium.

Natural diamond dies

- Natural diamond dies are used for drawing wires with diameters greater than 0.2 mm.

- They are also used for drawing wires made of soft materials such as copper and aluminum.

Tungsten carbide dies

- Tungsten carbide dies are used for drawing wires with diameters greater than 1.0 mm.

- They are also used for drawing wires made of hard materials such as steel and titanium.

3. What are the factors that affect the quality of a wire drawing die?

- The material of the die

- The shape and size of the die

- The surface finish of the die

- The lubrication used in the drawing process

- The drawing speed

4. What are the common defects that can occur in wire drawing dies and how can they be prevented?

- Cracking: This can be caused by excessive stress on the die or by using a die that is not properly hardened.

- Chipping: This can be caused by using a die that is not properly sharpened or by drawing wire that is too hard.

- Wear: This is a gradual process that can be caused by friction between the die and the wire.

Prevention

- Use dies that are made of high-quality materials.

- Properly harden and temper dies.

- Sharpen dies regularly.

- Use proper lubrication.

- Draw wire at the correct speed.

5. What are the latest trends in wire drawing die technology?

- The use of new materials such as PCD and CVD diamond.

- The development of new die designs that improve wire quality and reduce die wear.

- The use of computer-aided design and manufacturing (CAD/CAM) to design and manufacture dies.

6. What is the difference between a wet and dry wire drawing process?

- Wet drawing: In this process, a lubricant is used to reduce friction between the die and the wire.

- Dry drawing: In this process, no lubricant is used.

7. What are the advantages and disadvantages of wet and dry wire drawing?

Wet drawing

Advantages- Produces a better surface finish on the wire.

- Reduces die wear.

- Can be used to draw harder materials.

- Requires the use of a lubricant.

- Can be more expensive than dry drawing.

Dry drawing

Advantages- Does not require the use of a lubricant.

- Can be less expensive than wet drawing.

- Can produce a poorer surface finish on the wire.

- Can increase die wear.

- Cannot be used to draw harder materials.

8. What are the different types of lubricants used in wire drawing?

- Soap solutions

- Oil-based lubricants

- Solid lubricants

9. What are the factors that affect the choice of lubricant in wire drawing?

- The type of wire being drawn

- The drawing speed

- The die material

- The environmental conditions

10. What are the safety precautions that should be taken when working with wire drawing dies?

- Always wear safety glasses.

- Never touch a die with your bare hands.

- Use proper lifting techniques when handling dies.

- Store dies in a safe place.

- Dispose of dies properly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Drawing Die Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Drawing Die Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire Drawing Die Makers are responsible for creating and maintaining dies used in the production of wire. They work with engineers to design and develop dies, select materials, and set up and operate equipment to produce dies. They also maintain and repair dies to ensure that they meet specifications and produce quality wire.

1. Design Dies

Wire Drawing Die Makers need to be able to design dies that meet the specific requirements of the wire that is being produced. They must consider factors such as the material of the wire, the desired size and shape of the wire, and the speed at which the wire will be drawn. They also need to be able to determine the correct dimensions for the die and the type of material that will be used to make the die.

2. Select Materials

Wire Drawing Die Makers must be able to select the correct materials for the dies that they are making. They need to consider factors such as the material of the wire that is being drawn, the desired life of the die, and the cost of the material. They also need to be able to find suppliers who can provide the materials that they need.

3. Set Up and Operate Equipment

Wire Drawing Die Makers must be able to set up and operate the equipment that is used to produce dies. They need to be able to follow instructions and use the equipment safely. They also need to be able to troubleshoot problems and make adjustments to the equipment as needed.

4. Maintain and Repair Dies

Wire Drawing Die Makers must be able to maintain and repair dies to ensure that they are in good working condition. They need to be able to identify problems and make repairs quickly and efficiently. They also need to be able to keep records of the maintenance and repairs that they have performed.

Interview Preparation Tips

To prepare for an interview for a Wire Drawing Die Maker position, candidates should:

1. Research the Company and the Position

Candidates should take the time to learn as much as they can about the company and the specific position that they are applying for. They should visit the company’s website, read news articles about the company, and talk to people who work there. This will help them to understand the company’s culture and values, and to determine if they are a good fit for the position.

2. Practice Answering Interview Questions

Candidates should practice answering common interview questions. This will help them to feel more confident and prepared during the interview. They should also prepare questions to ask the interviewer, which will show that they are interested in the position and the company.

3. Dress Professionally

Candidates should dress professionally for the interview. They should wear clothes that are clean, pressed, and free of wrinkles. They should also avoid wearing clothes that are too revealing or too casual.

4. Be on Time

Candidates should be on time for the interview. Punctuality shows that they are respectful of the interviewer’s time. Candidates should arrive at the interview location 10-15 minutes early so that they have time to relax and prepare.

5. Be Yourself

Candidates should be themselves during the interview. They should not try to be someone that they are not. The interviewer will be able to tell if a candidate is being fake, and it will make a negative impression. Candidates should focus on highlighting their skills and experience, and on demonstrating why they are the best candidate for the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wire Drawing Die Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wire Drawing Die Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.