Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wire Drawing Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wire Drawing Machine Tender so you can tailor your answers to impress potential employers.

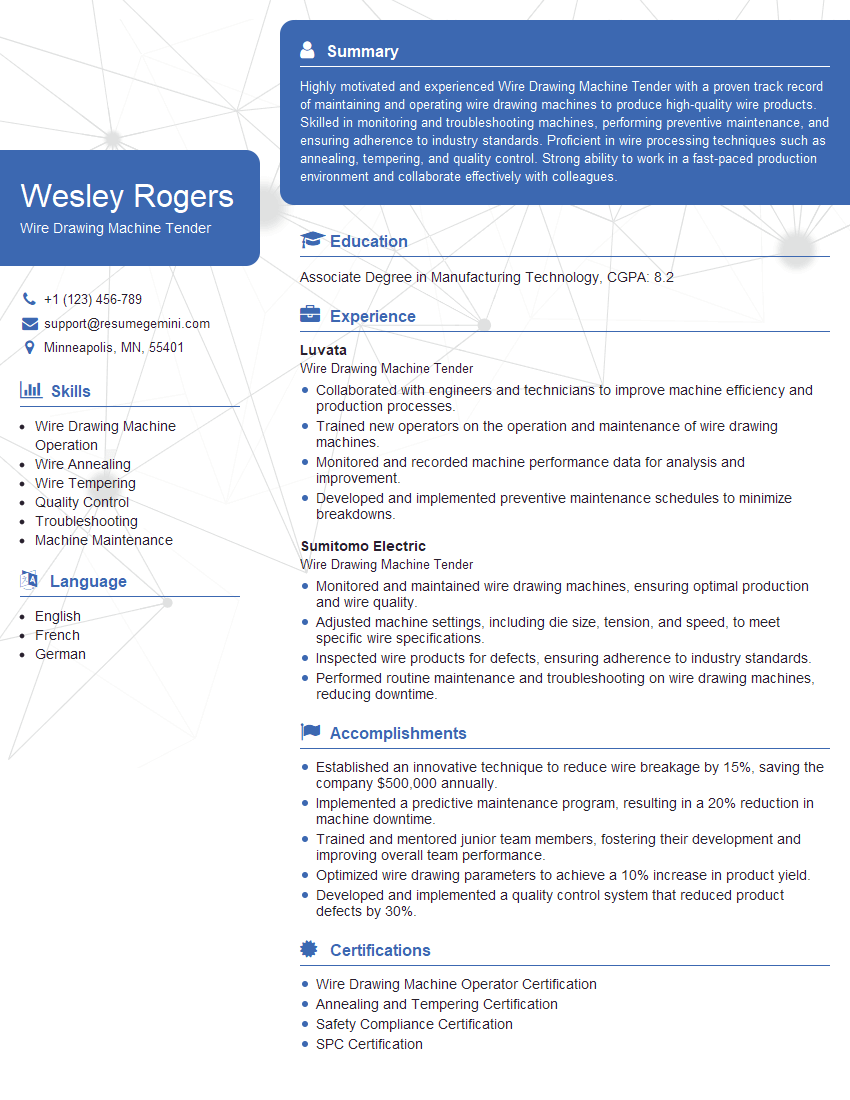

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Drawing Machine Tender

1. Describe the key responsibilities of a Wire Drawing Machine Tender?

- Operate and monitor wire drawing machines to produce various wire diameters and shapes.

- Set up and adjust machines, ensuring optimal operation and wire quality.

- Inspect wires for defects, taking corrective actions when necessary.

- Maintain and service machines, including lubrication, cleaning, and minor repairs.

- Follow established safety procedures and adhere to quality standards.

2. What are the common types of wire drawing machines, and how do they differ?

Single-die drawing

- Uses a single die to reduce the wire diameter in one pass.

- Suitable for drawing soft and ductile materials.

Multi-die drawing

- Uses multiple dies arranged in a series to gradually reduce the wire diameter.

- Produces wires with higher strength and dimensional accuracy.

Continuous drawing

- Draws wire continuously through a series of dies without stopping or starting.

- High production rates and improved wire quality.

3. How do you determine the appropriate die size and draw speed for a specific wire drawing operation?

- Consider the desired wire diameter and material properties.

- Refer to manufacturer’s recommendations and industry standards.

- Adjust draw speed based on wire material, die size, and desired surface finish.

- Monitor wire temperature and tension to prevent breakage or defects.

4. What are the common defects encountered in wire drawing, and how can they be prevented?

- Cracking: Prevented by using proper dies, lubricants, and drawing speeds.

- Decarburization: Prevented by controlling annealing and quenching processes.

- Scale formation: Prevented by using clean dies and wires, and applying lubricants.

- Surface roughness: Prevented by using clean dies, maintaining proper lubrication, and drawing at optimal speeds.

5. How do you maintain and calibrate wire drawing machines to ensure accuracy and efficiency?

- Regular lubrication and cleaning of components.

- Inspecting and replacing worn or damaged parts.

- Calibrating dies using precision measuring instruments.

- Checking wire diameters and dimensions against specifications.

- Following manufacturer’s recommended maintenance schedules.

6. What are the safety precautions to be taken while operating wire drawing machines?

- Wear appropriate safety gear, including gloves, eye protection, and earplugs.

- Inspect machines regularly and report any potential hazards.

- Avoid loose clothing or jewelry that could get caught in machinery.

- Follow lockout/tagout procedures when performing maintenance or repairs.

- Be aware of moving parts and potential pinch points.

7. How do you troubleshoot common wire drawing machine problems, such as wire breakage or defects?

- Identify the cause of the problem by examining the wire, dies, and machine settings.

- Adjust draw speed, tension, or lubrication as necessary.

- Inspect and replace worn or damaged dies or components.

- Check for proper die alignment and wire threading.

- Consult manufacturer’s documentation or seek assistance from experienced personnel if needed.

8. Describe the role of lubricants in wire drawing and their selection criteria.

- Lubricants reduce friction, heat generation, and wear on dies and wires.

- Selection criteria include lubricant type (e.g., oil-based, water-based), viscosity, and compatibility with wire material.

- Lubricants should provide adequate lubrication, prevent corrosion, and not contaminate the wire.

9. Explain the importance of annealing in wire drawing and its effect on wire properties.

- Annealing softens and increases the ductility of the wire.

- It removes work hardening caused by drawing, allowing for further drawing or forming operations.

- Annealing temperature and time affect the wire’s mechanical properties, such as strength and elongation.

10. How do you ensure that the drawn wire meets the required specifications and quality standards?

- Monitor wire diameter, surface finish, and mechanical properties during production.

- Conduct regular inspections and testing to verify conformance to specifications.

- Use calibrated measuring instruments and follow established quality control procedures.

- Document inspection results and take corrective actions if necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Drawing Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Drawing Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire Drawing Machine Tenders play a crucial role in manufacturing facilities by operating wire drawing machines to produce various types of wires used in construction, telecommunications, and other industries. Their primary responsibilities include:

1. Machine Operation and Maintenance

Set up and operate wire drawing machines according to established procedures.

- Monitor machine performance and make necessary adjustments to ensure optimal production.

- Perform routine maintenance tasks to keep machines in good working condition.

2. Material Handling

Load and unload wire coils onto the drawing machines.

- Inspect wire coils for defects and ensure they meet quality standards.

- Operate cranes or conveyors to move materials within the production area.

3. Process Control

Monitor the drawing process to ensure the desired wire dimensions and properties are achieved.

- Adjust process parameters such as speed, tension, and lubrication to optimize wire quality.

- Troubleshoot problems that arise during the drawing process and take corrective actions.

4. Safety and Quality Assurance

Adhere to safety regulations and follow proper procedures in the workplace.

- Inspect wires for defects and ensure they meet quality specifications.

- Report any safety or quality concerns to supervisors or technicians.

Interview Tips

To prepare effectively for an interview as a Wire Drawing Machine Tender, consider the following tips:

1. Research the Company and Position

Prior to the interview, familiarize yourself with the company’s background, products or services, and the specific requirements of the Wire Drawing Machine Tender position.

- This knowledge will enable you to demonstrate your understanding of the role and how your skills align with the company’s needs.

2. Practice Answering Common Interview Questions

Prepare thoughtful responses to common interview questions related to wire drawing machine operation, maintenance, and troubleshooting.

- Consider preparing for questions about your experience with different types of wire drawing machines, your problem-solving abilities, and your understanding of wire drawing processes.

3. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating and maintaining wire drawing machines. Provide specific examples of your experience in troubleshooting and resolving issues.

- Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

4. Demonstrate Your Safety Awareness

In the interview, underscore your commitment to safety in the workplace. Discuss your understanding of safety regulations and your experience in following proper procedures.

- Highlight any safety initiatives you have implemented or participated in.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and professional demeanor. Express your enthusiasm for the role and your ability to contribute to the company.

- Ask insightful questions about the position and the company to show your engagement and interest.

6. Research the Industry

Stay updated on the latest advancements and trends in the wire drawing industry. Attend industry events or read trade publications to demonstrate your dedication to professional development.

- This knowledge will showcase your eagerness to stay abreast of industry best practices.

7. Practice Active Listening

Pay close attention to the interviewer’s questions and respond thoughtfully and clearly. Ask clarifying questions to ensure you fully understand the interviewer’s intent.

- This demonstrates your engagement and interest in the conversation.

8. Prepare Questions For the Interviewer

At the conclusion of the interview, ask thoughtful questions about the company, the position, or the wire drawing industry.

- This shows your engagement and genuine interest in the opportunity.

9. Follow Up Professionally

After the interview, follow up promptly with a thank-you note to express your appreciation for the interviewer’s time and consideration.

- Reiterate your interest in the position and summarize your key qualifications.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wire Drawing Machine Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wire Drawing Machine Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.