Are you gearing up for a career in Wire Dropper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wire Dropper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

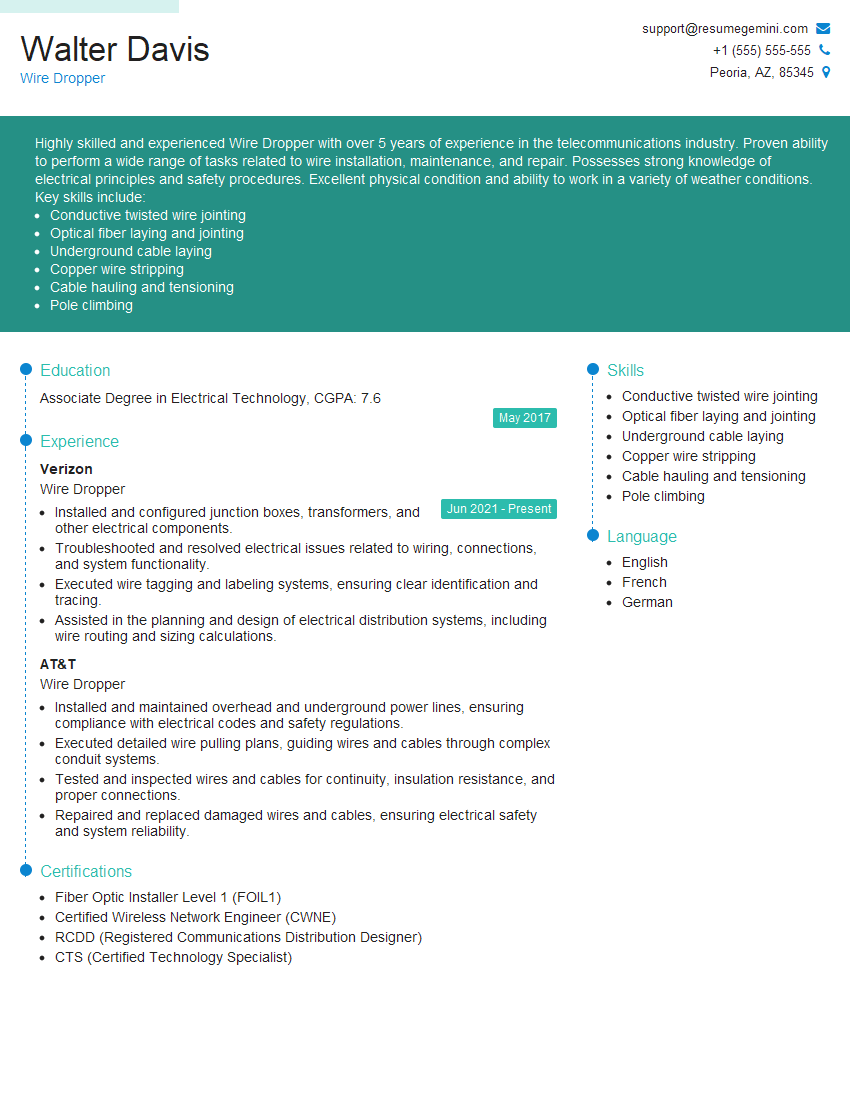

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Dropper

1. What are the different types of wire used in electrical installations and what are their respective applications?

There are various types of wire used in electrical installations, each with specific applications. Here are the most common types:

- Solid wire: Consists of a single, solid conductor strand. Used for low-voltage applications, such as in-wall wiring and appliance cords.

- Stranded wire: Comprises multiple, thin strands twisted together. More flexible than solid wire, making it suitable for applications where flexibility is required, such as extension cords and portable tools.

- Coaxial cable: Features an inner conductor surrounded by an insulating layer, a braided shield, and an outer insulating jacket. Used for transmitting high-frequency signals, such as in cable TV and internet connections.

- Twisted pair cable: Consists of two insulated conductor wires twisted together. Used for transmitting data and voice signals in telephone and computer networks.

- Electrical conduit: A protective pipe or tube through which electrical wires are run. Provides protection from damage, moisture, and tampering.

2. How do you determine the correct wire gauge for a given electrical application?

Factors to Consider:

- Current draw: Determined by the load (appliances or devices) connected to the circuit.

- Circuit length: Longer circuits experience greater voltage drop, requiring a larger wire gauge.

- Ambient temperature: Higher temperatures can affect the current-carrying capacity of wires.

- National Electrical Code (NEC) requirements: Provides guidelines for minimum wire gauge sizes based on these factors.

Calculation:

- Use Ohm’s law (V = IR) to calculate voltage drop (V) along the circuit.

- Refer to wire tables to determine the maximum allowable voltage drop for the specific wire type and insulation.

- Select a wire gauge that limits voltage drop within the acceptable range.

3. Explain the difference between AC and DC power and how it impacts wire selection.

AC (Alternating Current):

- Current flows in alternating directions, reversing polarity at regular intervals.

- Used in most household and commercial applications.

- Requires larger wire gauges compared to DC due to the higher current flow.

DC (Direct Current):

- Current flows in one direction only.

- Used in batteries, solar panels, and some electronic devices.

- Requires smaller wire gauges compared to AC for the same current flow.

4. What safety precautions should be taken when working with electrical wires?

- Lockout/tagout: De-energize circuits and prevent accidental reactivation.

- Proper grounding: Ensure proper grounding of equipment and tools.

- Use of insulated tools: Prevent electrical shock.

- Wear appropriate PPE: Including gloves, safety glasses, and flame-resistant clothing.

- Follow NEC guidelines: Adhere to industry standards for electrical safety.

5. Describe the process of properly splicing and terminating electrical wires.

Splicing:

- Strip insulation from both wires.

- Twist the exposed conductors together securely.

- Solder or use a wire nut to create a strong connection.

- Insulate the splice with electrical tape or heat shrink tubing.

Terminating:

- Strip insulation from the wire end.

- Insert the wire into a terminal block or connector.

- Tighten the screws or use a crimping tool to secure the connection.

- Insulate the termination with electrical tape or heat shrink tubing if necessary.

6. What is the purpose of a circuit breaker and how does it protect electrical systems?

A circuit breaker is a safety device that automatically interrupts an electrical circuit when the current flow exceeds a predetermined level.

- Operates on the principle of electromagnetism: When current exceeds the threshold, it creates a magnetic field that trips the breaker.

- Protects against overloads: When too much current is drawn, the breaker opens the circuit to prevent damage to wires and equipment.

- Serves as a backup to fuses: If a fuse fails, the circuit breaker provides an additional layer of protection.

7. Explain the concept of electrical resistance and how it affects wire selection and circuit design.

Electrical resistance is the opposition to the flow of current in a conductor. The higher the resistance, the more difficult it is for current to flow.

- Impact on wire selection: Wires with higher resistance require larger gauges to carry the same current without overheating.

- Effect on circuit design: Resistance limits the current flow in a circuit, affecting voltage drop and power dissipation.

- Factors affecting resistance: Material composition, length, cross-sectional area, and temperature.

8. Describe the different types of electrical insulators and their applications.

- Porcelain: High dielectric strength, used in outdoor applications and high-voltage systems.

- Glass: Excellent electrical resistance, used in capacitors and electronic components.

- Rubber: Flexible and moisture-resistant, used in electrical cables and connectors.

- Plastic: Lightweight and cost-effective, used in a wide range of electrical applications.

- Air: High dielectric strength, used in high-voltage equipment and transmission lines.

9. Explain the principle behind electrical grounding and its importance in electrical systems.

Electrical grounding is the process of connecting electrical equipment to the earth through a conductor.

- Safety: Provides a low-resistance path for fault currents, protecting users from electrical shock.

- Equipment protection: Directs surge currents and lightning strikes to the ground, preventing damage to equipment.

- Noise reduction: Acts as a reference point for electrical signals, minimizing electromagnetic interference.

10. Describe the process of installing and maintaining electrical conduit.

Installation:

- Select appropriate conduit size and type based on wire capacity, location, and code requirements.

- Cut and bend conduit to fit the desired path.

- Secure conduit using straps or clips.

- Pull wires through the conduit.

Maintenance:

- Inspect conduit for damage or corrosion.

- Tighten loose straps or clips.

- Ensure proper wire fill to prevent overheating.

- Clean or replace conduit as necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Dropper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Dropper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire droppers are the backbone of the electrical industry, responsible for the safe and efficient installation of electrical cables and wires. Key job responsibilities include:

1. Wire Installation and Maintenance

Installing, repairing, and replacing electrical wires and cables in residential, commercial, and industrial settings.

- Following blueprints and schematics to determine cable routes and connections.

- Using specialized tools and equipment to cut, strip, and connect wires.

2. Electrical System Analysis

Troubleshooting and diagnosing electrical system faults.

- Using testing equipment to identify electrical problems, such as short circuits and ground faults.

- Repairing or replacing faulty components.

3. Compliance with Safety Regulations

Ensuring adherence to all applicable electrical codes and safety regulations.

- Wearing proper protective gear, such as gloves and safety glasses.

- Following lock-out/tag-out procedures to prevent electrical accidents.

4. Communication and Teamwork

Collaborating with other electricians, contractors, and clients.

- Communicating project status, timelines, and potential challenges.

- Working cooperatively with team members to complete projects efficiently.

Interview Tips

To ace the interview for a wire dropper position, candidates should follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s values, services, and the specific requirements of the wire dropper role.

- Visit the company website, read job descriptions, and check industry forums.

- Prepare questions to ask the interviewer that demonstrate your interest in the company.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills, knowledge of electrical codes, and experience in wire installation and maintenance.

- Quantify your accomplishments, using specific examples to showcase your contributions.

- Explain how your skills align with the job requirements and the company’s needs.

3. Demonstrate Safety Consciousness

Convey your commitment to following safety protocols and ensuring a safe work environment.

- Highlight your knowledge of electrical safety regulations and best practices.

- Describe your experience with lock-out/tag-out procedures and other safety measures.

4. Showcase Teamwork and Communication

Emphasize your ability to work effectively in a team environment and communicate clearly with others.

- Provide examples of projects where you collaborated with other electricians.

- Explain your communication style and how you manage conflicts in a collaborative setting.

5. Be Confident and Enthusiastic

Convey a positive attitude, express your enthusiasm for the role, and demonstrate confidence in your abilities.

- Maintain eye contact, speak clearly, and ask thoughtful questions.

- End the interview by reiterating your interest in the position and thanking the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wire Dropper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!