Are you gearing up for an interview for a Wire Insulator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wire Insulator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

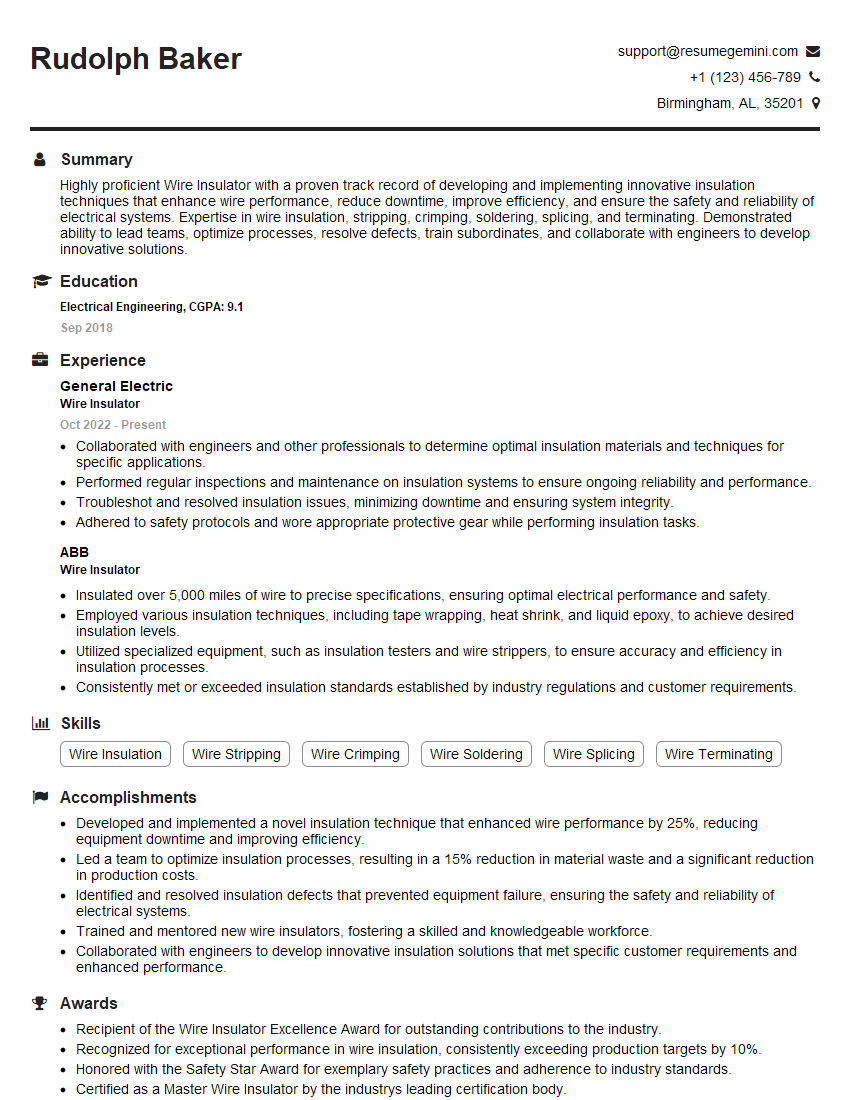

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Insulator

1. What are the different types of wire insulation materials?

There are various types of wire insulation materials, each with unique properties. Some of the most commonly used materials include:

- PVC (Polyvinyl Chloride): Widely used due to its affordability, flexibility, and resistance to moisture and abrasion.

- XLPE (Cross-Linked Polyethylene): Known for its high temperature resistance, electrical insulation properties, and resistance to chemicals.

- EPR (Ethylene Propylene Rubber): Offers excellent flexibility, resistance to heat, ozone, and chemicals, making it suitable for outdoor and industrial applications.

- Teflon (PTFE): Resists high temperatures, chemicals, and UV radiation, making it ideal for demanding applications such as aerospace and electronics.

- Silicone: Provides superior flexibility, high temperature resistance, and UV resistance, suitable for applications where flexibility and durability are crucial.

2. How do you determine the appropriate insulation thickness for a wire?

Factors Affecting Insulation Thickness

- Voltage Rating: Insulation thickness increases with higher voltage requirements.

- Environmental Conditions: Exposure to moisture, chemicals, or extreme temperatures affects insulation thickness.

- Wire Size: Thicker wires require thicker insulation to maintain proper electrical properties.

- Application: Different applications have specific insulation thickness requirements based on safety and performance considerations.

Calculation Methods

- Formula-Based Calculations: Using industry standards and formulas to determine the minimum required insulation thickness based on voltage rating and wire size.

- Reference Tables: Consulting published tables or manufacturer guidelines that provide insulation thickness recommendations for specific wire sizes and voltage ratings.

- Testing: Conducting electrical insulation tests to ensure that the insulation thickness meets the required specifications and provides adequate protection.

3. What are the key properties of a good wire insulation material?

- Electrical Insulation: The ability to prevent the flow of electricity between the conductor and its surroundings.

- Mechanical Strength: Resistance to abrasion, tearing, and impact to ensure wire integrity.

- Temperature Resistance: Withstanding high and low temperatures without degrading or compromising insulation properties.

- Chemical Resistance: Protecting the wire from the effects of chemicals, solvents, and corrosive substances.

- UV Resistance: Preventing degradation and discoloration caused by prolonged exposure to sunlight.

- Flexibility: Allowing for easy bending and routing of wires without compromising insulation integrity.

4. What are the different methods for testing wire insulation?

- High Voltage Testing: Applying high voltage to the insulated wire to test its electrical insulation strength and detect defects.

- Leakage Current Testing: Measuring the amount of current flowing through the insulation to assess its resistance to electrical breakdown.

- Dielectric Withstand Test: Subjecting the insulation to a specific voltage for a period of time to test its ability to withstand electrical stress.

- Partial Discharge Testing: Detecting and analyzing partial discharges within the insulation, which can indicate potential insulation weaknesses.

- Insulation Resistance Testing: Measuring the electrical resistance of the insulation to assess its ability to prevent current flow.

5. How do you ensure the quality of wire insulation during manufacturing?

- Material Inspection: Verifying the quality of incoming insulation materials to meet specified standards.

- Extrusion Process Control: Precisely controlling the extrusion process to ensure consistent insulation thickness, shape, and properties.

- In-Process Testing: Conducting regular testing during production to monitor insulation parameters and detect any deviations.

- Quality Assurance Inspections: Performing thorough inspections of finished insulated wires to ensure they meet required specifications.

- Statistical Process Control (SPC): Utilizing statistical methods to monitor and improve the insulation manufacturing process, reducing variability and defects.

6. What are the common causes of wire insulation failure?

- Overvoltage: Excessive voltage applied to the wire, causing electrical breakdown of the insulation.

- Mechanical Damage: Abrasion, crushing, or cutting of the insulation, compromising its protective properties.

- Environmental Factors: Exposure to extreme temperatures, moisture, or chemicals leading to degradation and insulation breakdown.

- Manufacturing Defects: Flaws or imperfections in the insulation material or manufacturing process causing weak points.

- Aging: Prolonged exposure to heat, UV radiation, or other factors causing gradual deterioration of the insulation.

7. How do you prevent wire insulation failure in harsh environments?

- Selecting Suitable Materials: Choosing insulation materials with high temperature resistance, chemical resistance, and UV resistance for harsh conditions.

- Proper Installation: Ensuring proper routing and installation practices to minimize mechanical stress and prevent damage to the insulation.

- Environmental Protection: Using protective conduits, enclosures, or cable trays to shield wires from extreme environments.

- Regular Maintenance and Inspection: Regularly inspecting wires for signs of damage or insulation degradation and addressing issues promptly.

- Quality Assurance: Adhering to strict quality control measures during manufacturing and installation to minimize the risk of defects and premature failure.

8. What are the latest advancements in wire insulation technology?

- Nanotechnology-Enhanced Insulation: Utilizing nanomaterials to improve insulation properties, such as electrical insulation, heat dissipation, and mechanical strength.

- Self-Healing Insulation: Developing materials that can autonomously repair insulation damage, improving reliability and reducing maintenance needs.

- Biodegradable Insulation: Creating environmentally friendly insulation materials that degrade naturally without harming the ecosystem.

- Wireless Insulation Monitoring: Incorporating sensors into the insulation to monitor its condition and provide real-time data for predictive maintenance.

- Advanced Extrusion Techniques: Utilizing precision extrusion methods to produce insulation with uniform thickness, smooth surfaces, and improved performance.

9. How do you stay updated with the latest wire insulation industry standards and best practices?

- Attending Conferences and Exhibitions: Participating in industry events to gain insights into new technologies, standards, and best practices.

- Subscribing to Industry Publications: Reading technical journals, magazines, and online resources to stay informed about the latest developments.

- Networking with Professionals: Connecting with peers, experts, and manufacturers to share knowledge and learn from industry experiences.

- Continuing Education: Enrolling in courses or workshops to enhance technical skills and stay current with industry trends.

- Collaborating with Suppliers: Working closely with insulation material suppliers to understand their latest products, capabilities, and advancements.

10. How do you manage quality control in wire insulation production?

- Raw Material Inspection: Verifying the quality and specifications of incoming insulation materials.

- In-Process Testing: Conducting regular tests during the extrusion and manufacturing process to monitor insulation properties and identify any deviations.

- Finished Product Testing: Performing comprehensive tests on completed insulated wires to ensure compliance with industry standards and customer requirements.

- Statistical Process Control (SPC): Implementing statistical methods to analyze production data, identify areas for improvement, and reduce variability.

- Continuous Improvement: Regularly reviewing quality data, identifying trends, and implementing corrective actions to enhance processes and product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Insulator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Insulator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire Insulators are responsible for applying a protective layer of insulation to electrical wires and cables. This insulation helps prevent electrical shorts, fires, and other hazards. Their primary role is to ensure that wires and cables are safe and meet industry standards.

1. Wire Insulation

Applying various types of insulation materials to wires and cables, such as rubber, plastic, or fiberglass, to protect them from electrical hazards and environmental conditions.

- Selecting the appropriate insulation material based on the wire’s intended use and environment.

- Using specialized equipment and techniques to apply insulation evenly and consistently.

2. Quality Control

Inspecting insulated wires and cables for defects or imperfections, such as breaks, tears, or improper insulation thickness.

- Conducting visual inspections and using testing equipment to ensure insulation meets specifications.

- Identifying and rectifying any non-compliant insulation to maintain product quality and safety.

3. Equipment Maintenance

Maintaining and calibrating insulation machinery and equipment to ensure optimal performance and accuracy.

- Cleaning and lubricating equipment regularly to prevent malfunctions and extend its lifespan.

- Following manufacturer’s guidelines for equipment maintenance and troubleshooting minor issues.

4. Safety Compliance

Adhering to all safety regulations and guidelines to minimize workplace hazards and accidents.

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Following established safety procedures for handling and using insulation materials and equipment.

Interview Tips

Preparing for an interview as a Wire Insulator requires research and practice. Here are some valuable tips to help you ace your interview:

1. Research the Company and Role

Familiarize yourself with the company’s website, LinkedIn page, and industry news to gain insights into their culture, values, and current projects.

- Research the specific job responsibilities and qualifications required for the Wire Insulator role.

- Identify areas where your skills and experience align with the job requirements.

2. Practice Common Interview Questions

Prepare for common interview questions related to your qualifications, experience, and motivation for the role.

- Practice answering questions about your experience with insulation materials, equipment, and safety procedures.

- Be prepared to discuss your understanding of industry standards and regulations.

3. Showcase Your Technical Skills

Highlight your technical habilidades by providing specific examples of your work experience.

- Describe your experience in applying insulation to different types of wires and cables.

- Mention any specialized techniques or equipment you have used in your previous roles.

4. Emphasize Safety and Attention to Detail

In this role, safety and attention to detail are paramount. Emphasize your commitment to following safety protocols and your ability to perform meticulous inspections.

- Share examples of how you have maintained a safe work environment in previous positions.

- Highlight your ability to identify and correct insulation defects or non-conformities.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wire Insulator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wire Insulator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.