Feeling lost in a sea of interview questions? Landed that dream interview for Wire Preparation Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wire Preparation Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

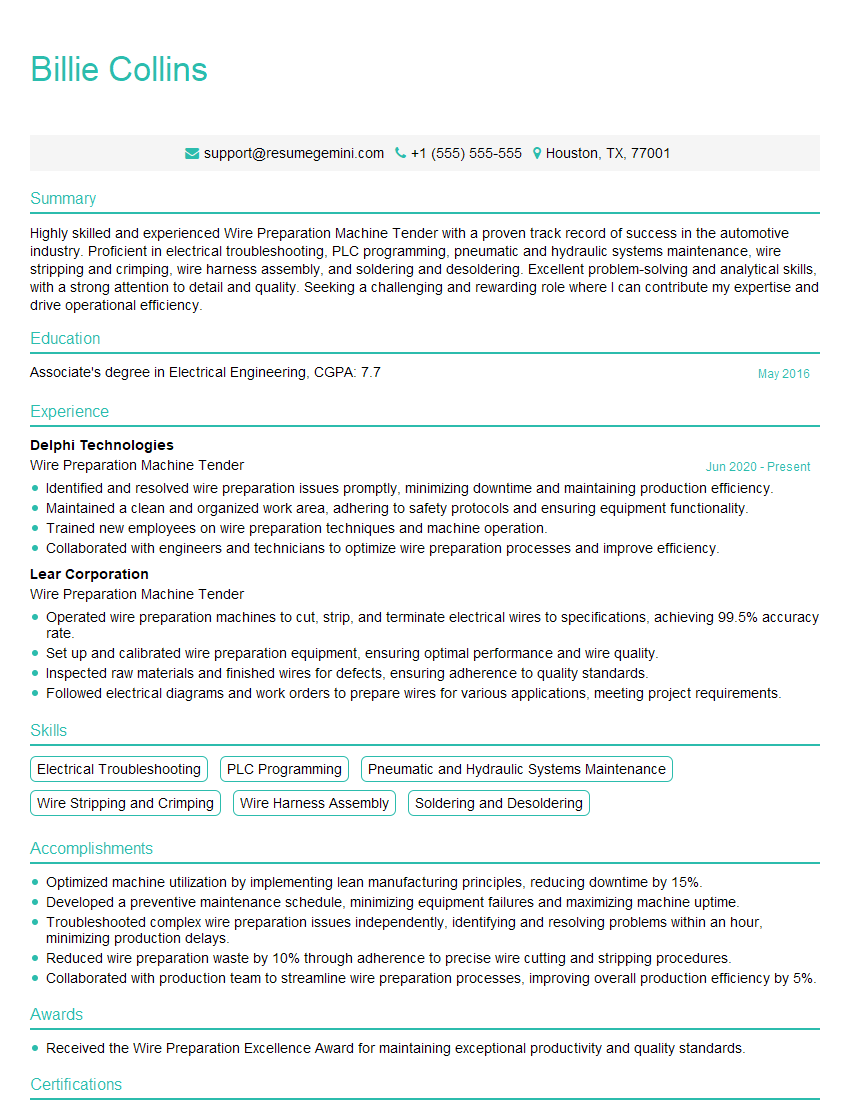

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Preparation Machine Tender

1. Describe the key responsibilities of a Wire Preparation Machine Tender?

- Operate and monitor wire preparation machines to prepare wires for assembly.

- Inspect wires for defects and ensure they meet specifications.

- Make necessary adjustments to machines to maintain optimal performance.

- Troubleshoot and resolve any issues with machines or wires.

- Maintain a clean and organized work area.

2. What are the different types of wire preparation machines and their functions?

- Coiling Machines: Used to form coils of wire.

- Stripping Machines: Used to remove insulation from wires.

- Cutting Machines: Used to cut wires to specific lengths.

- Crimping Machines: Used to attach terminals or connectors to wires.

- Soldering Machines: Used to solder wires together.

3. Explain the importance of wire preparation in the manufacturing process.

- Prepares wires for proper assembly and functioning.

- Ensures electrical conductivity and safety.

- Reduces the risk of short circuits and malfunctions.

- Improves the overall quality and reliability of the final product.

4. Describe the safety precautions you observe while operating wire preparation machines.

- Wear appropriate personal protective equipment (PPE).

- Keep work area clean and free of tripping hazards.

- Follow lock-out/tag-out procedures when servicing machines.

- Be aware of rotating parts and sharp edges.

- Use tools and equipment properly.

5. How do you troubleshoot common problems with wire preparation machines?

- Machine not starting: Check power supply, fuses, and connections.

- Wire not being cut or stripped properly: Check blade sharpness, machine settings, and wire type.

- Machine making excessive noise or vibration: Check bearings, gears, and other moving parts.

- Wire getting stuck in the machine: Check for blockages, tangles, or improper wire size.

- Electrical problems: Check wiring, connections, and insulation.

6. How do you maintain and calibrate wire preparation machines?

- Regular cleaning and lubrication

- Blade sharpening or replacement

- Sensor and gauge calibration

- Electrical checks and insulation testing

- Adherence to manufacturer’s maintenance schedule

7. Describe your experience in working with different types of wire materials.

- Copper: Soft and malleable, good electrical conductivity.

- Aluminum: Lightweight and corrosion-resistant, lower conductivity than copper.

- Steel: Strong and durable, not used for electrical applications.

- Stainless steel: Corrosion-resistant, used in harsh environments.

- Insulated wires: Covered with a protective layer.

8. How do you ensure the quality of wires prepared by the machine?

- Visual inspection: Check for cuts, nicks, or exposed strands.

- Electrical testing: Verify conductivity and insulation integrity.

- Dimensional measurements: Ensure compliance with specifications.

- Sampling and testing: Regular sampling to confirm machine performance.

9. Describe your experience in working in a team environment.

- Collaborate with colleagues: Share information and assist others.

- Maintain open communication: Report issues and updates promptly.

- Follow instructions: Adhere to established processes and procedures.

- Resolve conflicts: Work effectively with team members despite differences.

10. How do you stay updated on advancements in wire preparation technology?

- Attend industry conferences and workshops

- Read trade publications and technical articles

- Research new equipment and techniques online

- Network with professionals in the field

- Seek opportunities for professional development

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Preparation Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Preparation Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire Preparation Machine Tenders are responsible for operating and maintaining wire preparation machines, which are used to prepare wire for use in electrical and electronic products. They must have a strong understanding of the principles of wire preparation and be able to operate the machines safely and efficiently.

1. Set up and operate wire preparation machines

Involves ensuring that the machines are properly calibrated and adjusted, and that the correct materials are being used. Also involves monitoring the machines during operation to ensure that they are functioning properly.

- Set up and operate wire preparation machines according to specifications.

- Monitor machines during operation and make adjustments as needed.

2. Inspect wire before and after preparation

Involves checking the wire for defects and ensuring that it meets specifications. Also involves verifying that the wire has been prepared correctly according to engineering drawings and specifications.

- Inspect wire before and after preparation to ensure that it meets specifications.

- Identify and correct any defects in the wire.

3. Perform maintenance on wire preparation machines

Involves keeping the machines clean and in good working condition. Also involves troubleshooting and repairing minor problems.

- Perform maintenance on wire preparation machines to keep them in good working condition.

- Troubleshoot and repair minor problems with the machines.

4. Follow safety procedures

Involves adhering to all safety regulations and procedures. Also involves wearing the appropriate personal protective equipment and being aware of the potential hazards of the job.

- Follow all safety procedures and regulations.

- Wear the appropriate personal protective equipment.

- Be aware of the potential hazards of the job.

Interview Tips

Interviewing for a Wire Preparation Machine Tender position? Here are a few tips to help you ace your interview:

1. Research the company and the position

Take some time to learn about the company you’re interviewing with, as well as the specific position you’re applying for. This will help you to answer questions intelligently and show that you’re interested in the opportunity.

- Visit the company’s website to learn about their history, products, and services.

- Read articles and reviews about the company to get a sense of their reputation.

- Check out the job description and make sure you understand the requirements of the position.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Prepare for questions about your experience, skills, and qualifications.

- Be able to articulate why you’re interested in the position and why you’re a good fit for the company.

- Have questions ready to ask the interviewer about the company and the position.

3. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally for your interview. Also, be sure to arrive on time, as punctuality shows that you respect the interviewer’s time.

- Dress in a suit or business casual attire.

- Be neat and well-groomed.

- Arrive on time for your interview.

4. Be confident and enthusiastic

Confidence is key in any interview, so make sure you project a positive and enthusiastic attitude. Be yourself and let your personality shine through, as this will help you to make a good impression on the interviewer.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be positive and enthusiastic about the opportunity.

- Be yourself and let your personality shine through.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wire Preparation Machine Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.