Feeling lost in a sea of interview questions? Landed that dream interview for Wire Rope Fabrication Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wire Rope Fabrication Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

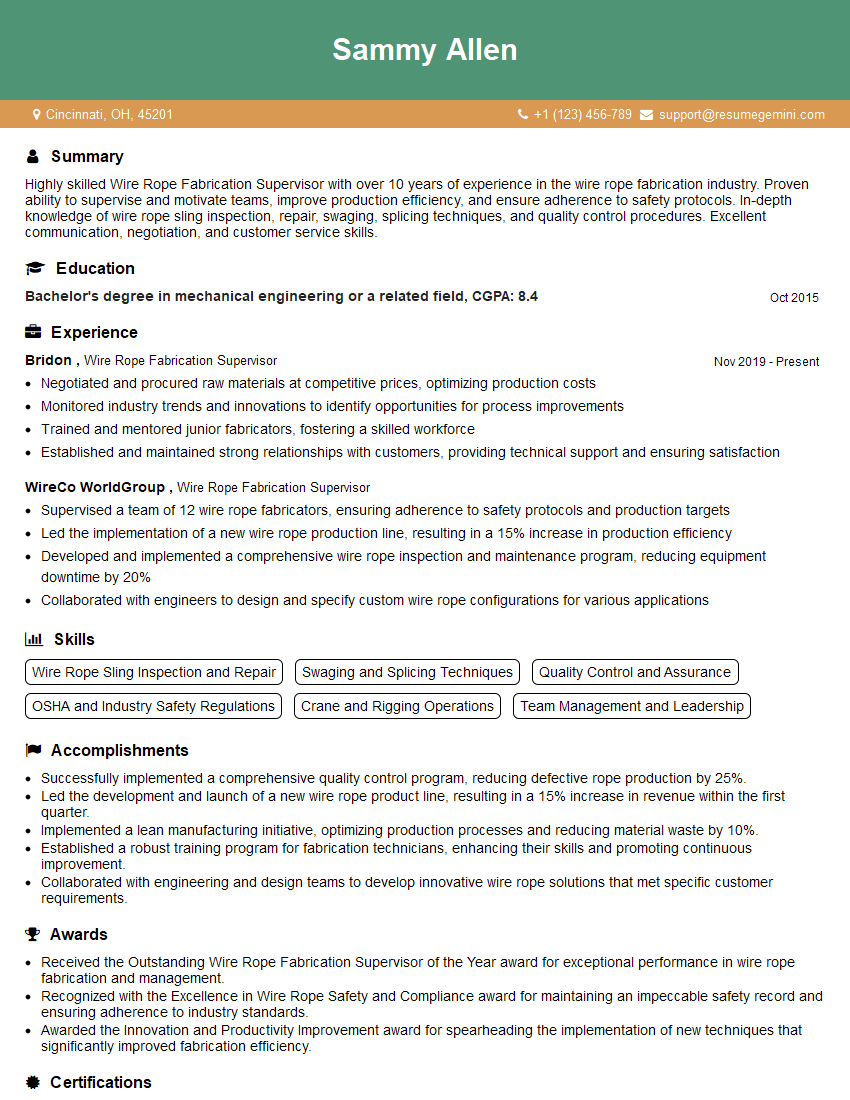

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Rope Fabrication Supervisor

1. What is the difference between a swaged fitting and a socketed fitting?

Sure, here are the key differences between swaged fittings and socketed fittings:

- Swaged fittings are attached to the wire rope by compressing a metal sleeve around the rope. This creates a permanent, high-strength connection.

- Socketed fittings are attached to the wire rope by inserting the rope into a socket and then pouring molten metal around the rope. This also creates a permanent, high-strength connection.

- Swaged fittings are generally smaller and lighter than socketed fittings.

- Socketed fittings are more expensive than swaged fittings.

- Swaged fittings are easier to install than socketed fittings.

2. What are the different types of wire rope constructions?

Lay

- Regular lay: This is the most common type of lay. The strands are twisted in one direction, and the wires are twisted in the opposite direction.

- Lang lay: In this type of lay, the strands and the wires are twisted in the same direction.

Number of Strands

- 6×19: This means that the rope has 6 strands, each of which is made up of 19 wires.

- 6×36: This means that the rope has 6 strands, each of which is made up of 36 wires.

- 8×19: This means that the rope has 8 strands, each of which is made up of 19 wires.

Core

- Fiber core (FC): This type of core is made of natural or synthetic fibers, such as sisal or polyester.

- Independent wire rope core (IWRC): This type of core is made of a separate wire rope.

3. What are the factors to consider when selecting wire rope?

When selecting wire rope, it is important to consider the following factors:

- Load capacity: The wire rope must be strong enough to handle the load that it will be subjected to.

- Construction: The construction of the wire rope will affect its strength, flexibility, and durability.

- Diameter: The diameter of the wire rope will affect its strength and flexibility.

- Length: The length of the wire rope will affect its weight and cost.

- Environment: The environment in which the wire rope will be used will affect its durability.

4. What are the common causes of wire rope failure?

The common causes of wire rope failure include:

- Abrasion: This is the most common cause of wire rope failure. It occurs when the wire rope comes into contact with a hard surface, such as a rock or a metal object.

- Fatigue: This occurs when the wire rope is subjected to repeated bending or flexing. Over time, this can cause the wires to break.

- Corrosion: This occurs when the wire rope is exposed to moisture or chemicals. This can cause the wires to rust and weaken.

- Overloading: This occurs when the wire rope is subjected to a load that exceeds its capacity.

- Improper installation or maintenance: This can also lead to wire rope failure.

5. What are the different methods of wire rope inspection?

There are several different methods of wire rope inspection, including:

- Visual inspection: This is the most basic method of inspection. It involves looking for any visible damage, such as broken wires, kinks, or corrosion.

- Magnetic particle inspection: This method uses a magnetic field to detect cracks and other defects in the wire rope.

- Ultrasonic inspection: This method uses sound waves to detect internal defects in the wire rope.

- Eddy current inspection: This method uses electromagnetic fields to detect surface defects in the wire rope.

6. What are the different types of wire rope terminations?

There are several different types of wire rope terminations, including:

- Swaged fittings: These fittings are attached to the wire rope by compressing a metal sleeve around the rope.

- Socketed fittings: These fittings are attached to the wire rope by inserting the rope into a socket and then pouring molten metal around the rope.

- Mechanical splices: These splices are made by mechanically joining two pieces of wire rope together.

- Hand splices: These splices are made by hand-braiding the ends of two pieces of wire rope together.

7. What are the safety precautions that should be taken when working with wire rope?

When working with wire rope, it is important to take the following safety precautions:

- Inspect the wire rope before each use.

- Do not use wire rope that is damaged.

- Wear gloves when handling wire rope.

- Do not stand under a suspended load.

- Be aware of the potential for wire rope to recoil.

8. What are the different types of equipment used in wire rope fabrication?

The different types of equipment used in wire rope fabrication include:

- Wire rope cutting machines: These machines are used to cut wire rope to the desired length.

- Wire rope swaging machines: These machines are used to attach swaged fittings to wire rope.

- Wire rope socketing machines: These machines are used to attach socketed fittings to wire rope.

- Wire rope splicing machines: These machines are used to make mechanical splices in wire rope.

- Wire rope testing machines: These machines are used to test the strength and durability of wire rope.

9. What are the quality control procedures that should be followed in wire rope fabrication?

The following quality control procedures should be followed in wire rope fabrication:

- Inspect the raw materials.

- Follow the manufacturer’s instructions for fabrication.

- Test the finished product.

- Document the quality control process.

10. What are the challenges facing the wire rope fabrication industry?

The wire rope fabrication industry faces a number of challenges, including:

- The rising cost of raw materials.

- The increasing demand for high-quality wire rope.

- The need to improve productivity.

- The need to reduce environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Rope Fabrication Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Rope Fabrication Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Wire Rope Fabrication Supervisor, you will be responsible for overseeing the production of wire rope and ensuring that it meets all quality standards. Your key responsibilities will include:

1. Managing production operations

You will be responsible for planning, scheduling, and controlling all aspects of wire rope production. This will include:

- Developing production schedules

- Assigning tasks to employees

- Monitoring production progress

- Ensuring that all production meets quality standards

2. Maintaining equipment

You will be responsible for maintaining all equipment used in the production of wire rope. This will include:

- Performing regular maintenance checks

- Troubleshooting and repairing equipment problems

- Ordering and installing new equipment

3. Managing inventory

You will be responsible for managing the inventory of raw materials, work-in-progress, and finished goods. This will include:

- Ordering raw materials

- Tracking inventory levels

- Ensuring that inventory is stored properly

4. Training and supervising employees

You will be responsible for training and supervising all employees in the wire rope fabrication department. This will include:

- Training employees on production processes

- Supervising employees and providing feedback

- Ensuring that employees are following safety procedures

Interview Tips

Here are some tips to help you ace your interview for a Wire Rope Fabrication Supervisor position:

1. Research the company and the position

Before your interview, be sure to do your research on the company and the position. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific responsibilities of the position and what the company is looking for in a candidate.

2. Practice your answers to common interview questions

There are certain questions that are commonly asked in interviews for Wire Rope Fabrication Supervisor positions. These questions include:

- Tell me about your experience in wire rope fabrication.

- What are your strengths and weaknesses as a supervisor?

- How would you handle a conflict between two employees?

- What are your goals for the future?

It is important to think about these questions in advance and prepare your answers. You should also practice answering these questions out loud so that you can become more comfortable with the process.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean, pressed, and fit well.

4. Be confident and enthusiastic

Confidence and enthusiasm are key in any interview, but they are especially important in interviews for leadership positions. When you are confident and enthusiastic, you show the interviewer that you are excited about the position and that you are confident in your abilities. You also make a more positive impression on the interviewer.

5. Follow up after the interview

After your interview, be sure to send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and consideration. You can also use the thank-you note to reiterate your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wire Rope Fabrication Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.