Are you gearing up for a career in Wire Strander? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wire Strander and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

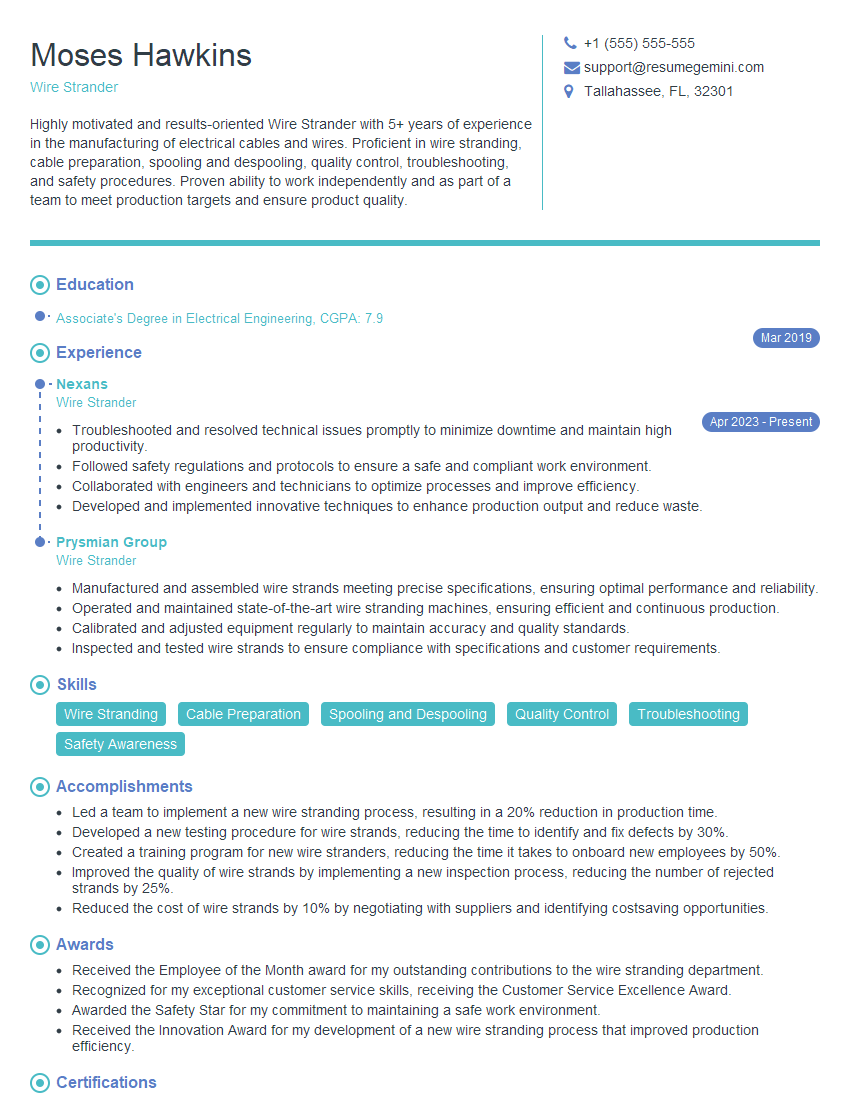

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Strander

1. What are the different types of wire stranding machines and their applications?

There are various types of wire stranding machines, each designed for specific applications. The most common types include:

- Bunching machine: Used to twist multiple individual wires together to form a bunched conductor.

- Laying-up machine: Lays multiple bunched conductors together to create a stranded conductor with a specific lay length.

- Cabling machine: Combines multiple stranded conductors to form a cable with a desired number of layers and lay lengths.

- Armoring machine: Applies a layer of protective material, such as steel tape or wire, over stranded conductors to enhance durability.

- Shielding machine: Wraps a conductive or non-conductive material around the stranded conductor to provide electrical shielding.

2. How do you calculate the lay length of a stranded conductor?

Formula:

- Lay Length (LL) = (π * Conductor Diameter * Number of Strands) / (Number of Strands – 1)

Explanation:

- Conductor Diameter: Diameter of each individual wire being stranded.

- Number of Strands: Total number of wires in the stranded conductor.

3. What factors influence the selection of stranding type and lay length?

The selection of stranding type and lay length depends on several factors, including:

- Electrical performance: Lay length affects the electrical properties, such as inductance and capacitance.

- Mechanical properties: Stranding type and lay length impact flexibility, crush resistance, and tensile strength.

- Application requirements: The intended use of the stranded conductor, such as high-frequency applications or harsh environments.

- Cost: Different stranding methods and lay lengths vary in terms of production cost.

4. Describe the process of setting up and operating a wire stranding machine.

Setting up and operating a wire stranding machine typically involves the following steps:

- Machine preparation: Calibrating the machine, installing the desired stranding dies, and setting the lay length.

- Wire preparation: Cleaning and straightening the wires to be stranded.

- Wire feeding: Feeding the wires into the machine using wire pay-off stands.

- Stranding: Running the machine to twist and lay the wires together.

- Coiling: Winding the stranded conductor onto a take-up reel.

- Quality control: Checking the conductor’s dimensions, electrical properties, and compliance with specifications.

5. What are the common troubleshooting techniques for wire stranding machines?

Common troubleshooting techniques for wire stranding machines include:

- Wire breakage: Inspect for wire defects, adjust tension settings, or lubricate the dies.

- Uneven lay: Check the machine calibration, stranding dies, and wire tension.

- Electrical faults: Verify proper grounding, check insulation, and inspect electrical connections.

- Mechanical issues: Inspect gears, bearings, and drive systems for wear or damage.

- Control system errors: Troubleshoot PLC or HMI issues, check sensors, and verify proper programming.

6. How do you ensure the quality of stranded conductors?

Quality assurance measures for stranded conductors include:

- Raw material inspection: Checking the quality of incoming wires.

- Process monitoring: Regularly monitoring the stranding process to ensure compliance with specifications.

- Dimensional inspection: Measuring the conductor’s diameter, lay length, and other dimensions.

- Electrical testing: Conducting electrical tests to verify insulation resistance, capacitance, and inductance.

- Visual inspection: Examining the conductor’s surface for defects, such as burrs or scratches.

7. What are the safety precautions to be observed when operating a wire stranding machine?

To ensure safety, it is crucial to adhere to the following precautions:

- Machine guarding: Ensure proper guarding around moving parts to prevent accidents.

- Personal protective equipment: Wear appropriate PPE, such as safety glasses, gloves, and earplugs.

- Wire handling: Use proper techniques for handling wires and avoid sharp edges.

- Electrical safety: Follow electrical safety protocols, including grounding and insulation checks.

- Emergency procedures: Be familiar with emergency stop procedures and evacuation routes.

8. What are the latest trends and advancements in wire stranding technology?

The wire stranding industry is constantly evolving, with new technologies emerging to improve efficiency and quality. Some trends include:

- Automated systems: Automation in stranding machines reduces manual labor and improves accuracy.

- Advanced control systems: Sophisticated control systems allow for precise adjustments and monitoring.

- New materials: Development of new materials with enhanced electrical and mechanical properties.

- Additive manufacturing: 3D printing techniques are used to create custom stranding dies.

9. How do you stay up-to-date with the latest industry standards and best practices for wire stranding?

To stay updated with industry developments, I regularly:

- Attend industry events: Conferences and trade shows provide opportunities to learn about new technologies and best practices.

- Read industry publications: Subscribe to trade magazines and technical journals to stay informed about industry trends.

- Network with peers: Connect with other professionals in the field to exchange knowledge and ideas.

- Seek professional development: Participate in workshops, seminars, and online courses to enhance my skills.

10. What are your strengths and weaknesses as a Wire Strander?

Strengths: (Mention 3-4 strengths relevant to the job)

- Technical expertise: Proficient in wire stranding machine operation, troubleshooting, and quality control.

- Attention to detail: Meticulous in following specifications and ensuring high-quality output.

- Problem-solving skills: Capable of diagnosing and resolving equipment issues efficiently.

- Safety consciousness: Strong adherence to safety protocols and commitment to a safe work environment.

Weaknesses: (Mention 1-2 weaknesses and how you are addressing them)

- Knowledge of advanced control systems: Limited experience with the latest control systems. Actively seeking opportunities to expand my knowledge in this area.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Strander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Strander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Wire Strander is accountable for handling and operating wire stranding machines to create different types of wire for electrical and telecommunications purposes. They ensure that the machines are operating smoothly and efficiently, and that the wire produced meets the required standards.

1. Machine Operation

Ensuring proper functioning of the wire stranding machine

- Setting up and adjusting machine parameters

- Monitoring machine performance

2. Wire Production

Producing different types and gauges of wire

- Selecting and loading wire onto the machine

- Setting up the machine for the desired wire configuration

3. Quality Control

Verifying wire quality and adhering to standards

- Inspecting wire for defects

- Conducting quality control tests

4. Equipment Maintenance

Performing basic maintenance and troubleshooting

- Cleaning and lubricating machine components

- Replacing faulty parts

Interview Tips

Preparing for an interview for the position of Wire Strander requires a thorough understanding of the job responsibilities and the skills and experience needed. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Learn about the company’s history, products, and services. This will show the interviewer that you are interested in the position and the company.

- Visit the company’s website and social media pages.

- Read industry news and articles.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked. Practice answering these questions in advance so that you can deliver clear and concise responses.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you the opportunity to learn more about the company and the culture.

- What are the biggest challenges facing the wire stranding industry?

- What are the company’s plans for growth in the future?

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you take the interview seriously.

- Wear a suit or business casual attire.

- Be punctual and arrive at least 15 minutes early.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wire Strander role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.