Are you gearing up for a career in Wire Stripping Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wire Stripping Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

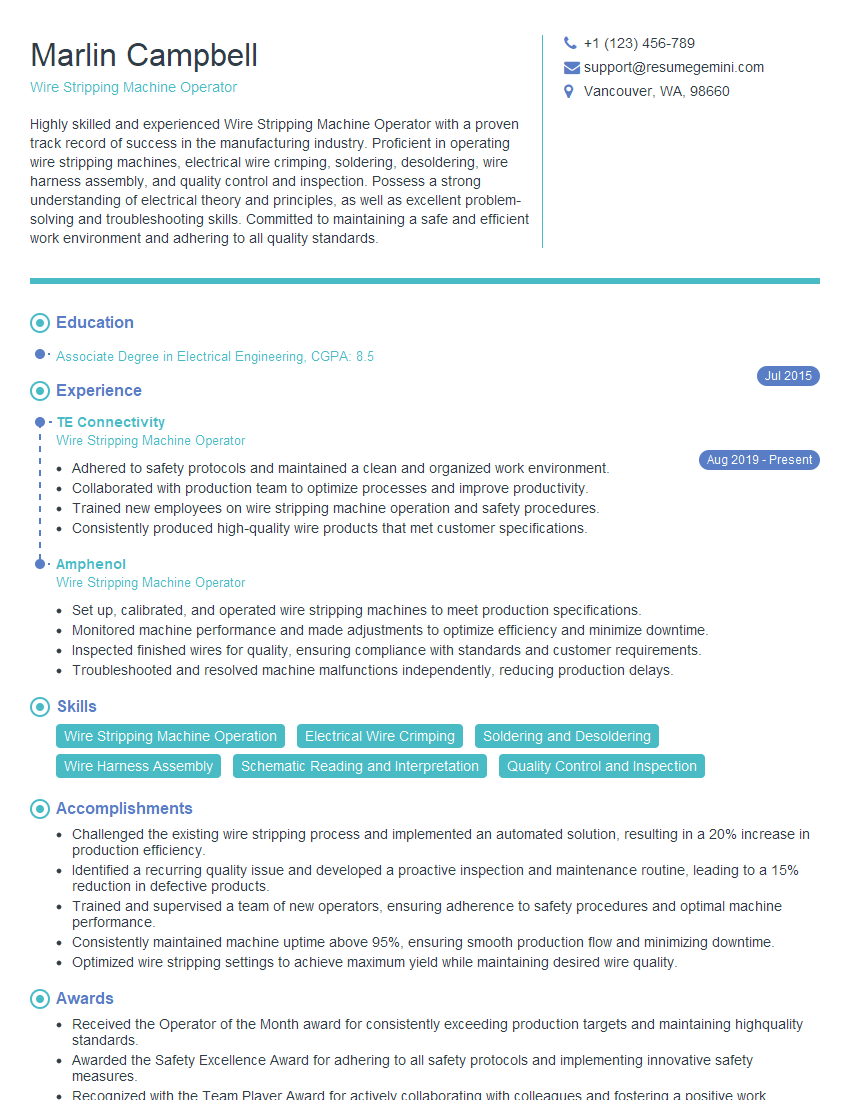

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Stripping Machine Operator

1. Describe the process of wire stripping using a wire stripping machine.

The process of wire stripping using a wire stripping machine involves the following steps:

- Loading the wire: The wire is loaded onto the machine’s feed tray.

- Positioning the wire: The wire is positioned between the machine’s stripping blades.

- Activating the machine: The machine’s stripping blades are activated, rotating at high speed.

- Stripping the wire: The rotating blades cut through the wire’s insulation, exposing the bare conductor.

- Collecting the stripped wire: The stripped wire is collected in a designated receptacle.

2. What are the different types of wire stripping machines available?

Manual Wire Stripping Machines

- Require manual operation of the stripping blades.

- Suitable for small-scale or hobbyist use.

Semi-Automatic Wire Stripping Machines

- Offer some level of automation, such as automatic wire feeding.

- Increase efficiency and precision compared to manual machines.

Fully-Automatic Wire Stripping Machines

- Completely automated, handling all aspects of the stripping process.

- Suitable for high-volume production environments.

3. How do you determine the correct settings for a wire stripping machine based on wire specifications?

To determine the correct settings for a wire stripping machine based on wire specifications, the following factors need to be considered:

- Wire diameter: The machine’s stripping blades should be adjusted to match the diameter of the wire.

- Insulation type: Different types of insulation require different stripping forces. The machine should be set accordingly.

- Strip length: The machine needs to be programmed to strip the desired length of insulation.

4. What are the common problems encountered while operating a wire stripping machine and how do you troubleshoot them?

Common problems encountered while operating a wire stripping machine include:

- Inconsistent stripping: Ensure the machine’s settings are correct and the blades are sharp.

- Damage to the wire: Adjust the stripping force or use a different type of blade.

- Machine overheating: Allow the machine to cool down or check for proper lubrication.

5. What are the safety precautions to observe when operating a wire stripping machine?

Important safety precautions to observe when operating a wire stripping machine include:

- Wear appropriate protective gear: Gloves, safety glasses, and hearing protection.

- Keep the work area clean and free of debris: This helps prevent accidents and damage to the machine.

- Follow the manufacturer’s instructions: Refer to the machine’s manual for proper operation and maintenance procedures.

6. What is the importance of regular maintenance for a wire stripping machine?

Regular maintenance for a wire stripping machine is crucial for ensuring:

- Optimal performance: Regular cleaning and lubrication keep the machine running smoothly.

- Increased lifespan: Proper maintenance extends the machine’s life and reduces the risk of breakdowns.

- Safety: Well-maintained machines are less likely to pose safety hazards.

7. How do you handle situations where the wire stripping machine produces defective or non-conforming wires?

When the wire stripping machine produces defective or non-conforming wires, the following steps can be taken:

- Identify the root cause: Check the machine settings, wire specifications, and any potential malfunctions.

- Make necessary adjustments: Calibrate the machine, replace blades, or adjust the stripping force as needed.

- Inspect and rework: Identify the defective wires, remove them from the production line, and rework them if possible.

8. Describe the different types of wire insulation materials and their stripping challenges.

PVC Insulation

- Strips easily with standard blades.

XLPE Insulation

- More difficult to strip, requires sharper blades and higher stripping force.

PTFE Insulation

- Highly resistant to heat and chemicals, requires specialized blades and techniques.

9. How do you optimize the efficiency and accuracy of a wire stripping machine?

To optimize the efficiency and accuracy of a wire stripping machine:

- Calibrate the machine regularly: Ensure precise settings for wire diameter, insulation type, and strip length.

- Use sharp blades: Dull blades can lead to inconsistent stripping and damage to the wire.

- Lubricate the machine: Proper lubrication reduces friction and extends the machine’s life.

10. What are the quality control procedures involved in wire stripping operations?

Quality control procedures in wire stripping operations include:

- Visual inspection: Examining the stripped wires for any defects or non-conformities.

- Dimensional measurements: Verifying the strip length and wire diameter meet specifications.

- Electrical testing: Ensuring the stripped wire maintains its electrical properties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Stripping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Stripping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wire Stripping Machine Operator is an essential member of electrical manufacturing and repair teams, responsible for stripping insulation from electrical wires using a specialized machine. Their key job responsibilities include:

1. Machine Operation

Operate and maintain wire stripping machines to efficiently remove insulation from electrical wires.

- Set up machines according to specified wire sizes and insulation types.

- Adjust machine parameters to achieve optimal stripping quality.

2. Quality Control

Inspect stripped wires to ensure they meet required specifications and standards.

- Check for proper insulation removal and absence of nicks or cuts on conductors.

- Identify and rectify any defects in the stripping process.

3. Material Handling

Handle and manage electrical wires and other materials efficiently.

- Load and unload wires from the stripping machine.

- Maintain an organized and safe work area.

4. Troubleshooting

Identify and resolve common issues that may arise during the stripping process.

- Diagnose and rectify machine malfunctions.

- Troubleshoot and resolve issues with wire quality or insulation removal.

Interview Tips

Preparing thoroughly for an interview is crucial for showcasing your skills and increasing your chances of success. Here are some tips to help you ace your interview for a Wire Stripping Machine Operator position:

1. Research the Company and Role

Gather information about the company’s industry, products, and culture. Understanding the specific requirements of the role will help you tailor your answers to the interviewer’s questions.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating wire stripping machines and your attention to detail. Quantify your accomplishments whenever possible to demonstrate your impact.

- Provide specific examples of successful troubleshooting or quality control measures you implemented.

- Mention any certifications or training you have completed.

3. Be Prepared for Technical Questions

Expect to be asked questions about the technical aspects of wire stripping. Brush up on your knowledge of different wire types, insulation materials, and machine settings.

- Practice answering questions about machine calibration and maintenance.

- Be ready to discuss your understanding of electrical safety protocols.

4. Practice Active Listening and Communication

Demonstrate your ability to listen attentively to the interviewer’s questions and respond clearly and concisely. Ask clarifying questions when needed to show your engagement and understanding.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Maintain eye contact and speak confidently.

5. Prepare Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the role. Prepare questions about the company’s growth plans, training opportunities, or any specific challenges the team is facing.

- Avoid asking generic or personal questions.

- Tailor your questions to the specific company and role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wire Stripping Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.