Are you gearing up for an interview for a Wire Winder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wire Winder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

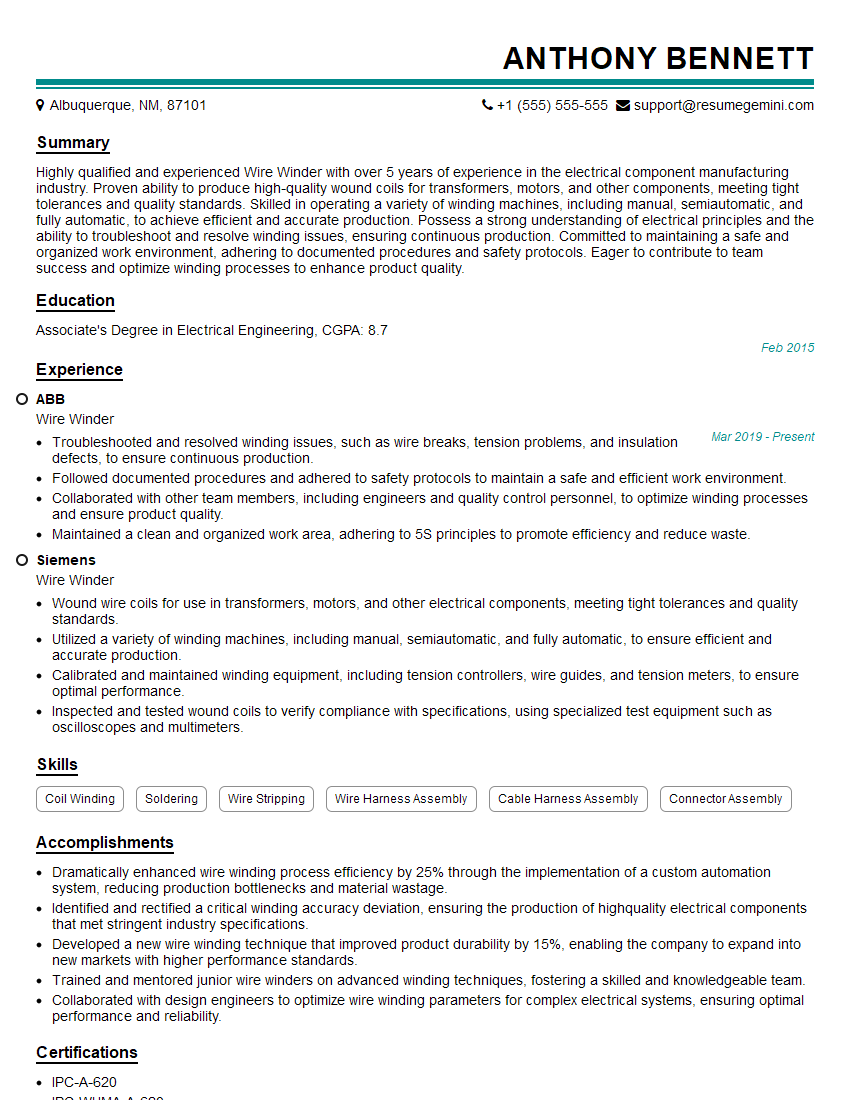

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Winder

1. What are the different types of wire winding machines you have experience with?

In my previous role, I worked with various types of wire winding machines, including:

- Single-head winding machines

- Dual-head winding machines

- Turntable winding machines

- CNC winding machines

2. What are the key parameters to consider when selecting the winding speed for a given application?

Factors affecting winding speed:

- Wire gauge

- Bobbin size

- Motor power

- Desired winding tension

Impact of winding speed on:

- Wire quality

- Bobbin temperature

- Production efficiency

3. How do you ensure the proper tension of the wire during winding?

To ensure proper wire tension during winding, I employ the following techniques:

- Calibrating the tension control system

- Monitoring tension levels throughout the winding process

- Adjusting the tension as needed based on wire type and winding parameters

- Using tension sensors to provide feedback to the winding machine

4. What are the steps involved in troubleshooting a wire winding machine?

My troubleshooting process for wire winding machines typically involves the following steps:

- Identifying the problem and its symptoms

- Checking electrical connections and power supply

- Inspecting mechanical components for wear or damage

- Calibrating sensors and adjusting settings

- Replacing faulty components as necessary

5. How do you maintain and calibrate a wire winding machine?

To ensure optimal performance and accuracy, I adhere to the following maintenance and calibration procedures for wire winding machines:

- Regular cleaning and lubrication of components

- Checking and adjusting tension control systems

- Calibrating sensors and gauges

- Following manufacturer’s maintenance schedules

- Keeping a log of maintenance activities for future reference

6. What types of wire insulation materials are you familiar with and how do they impact the winding process?

I have experience working with a range of wire insulation materials, including:

- Enamel

- Polyurethane

- Nylon

- Polyester

The type of insulation material used affects factors such as:

- Temperature rating

- Abrasion resistance

- Electrical properties

- Chemical resistance

7. What techniques do you use to achieve high-quality, precision winding?

To achieve high-quality, precision winding, I employ the following techniques:

- Using specialized winding machines with accurate controls

- Selecting the appropriate wire gauge and insulation material

- Calibrating the tension control system

- Monitoring winding parameters throughout the process

- Implementing quality control measures to ensure consistency

8. How do you handle and store wire to prevent damage or contamination?

To prevent damage or contamination of wire, I follow these handling and storage practices:

- Using proper spools or reels for winding and storage

- Storing wire in a clean, dry environment

- Protecting wire from moisture, dust, and chemicals

- Inspecting wire before use to ensure its integrity

- Following manufacturer’s recommendations for storage and handling

9. What safety precautions do you take when operating wire winding machines?

To ensure safety when operating wire winding machines, I adhere to the following precautions:

- Wearing appropriate safety gear, including gloves and safety glasses

- Checking the machine’s condition and guarding before operation

- Keeping the work area clean and free of hazards

- Following lockout/tagout procedures

- Being aware of potential hazards, such as pinch points and rotating parts

10. How do you stay up-to-date on the latest advancements in wire winding technology?

I stay informed about the latest advancements in wire winding technology through the following methods:

- Attending industry conferences and exhibitions

- Reading technical articles and journals

- Consulting with industry experts

- Participating in online forums and discussion groups

- Exploring new technologies at trade shows

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wire Winder is responsible for operating and maintaining wire winding machines to produce electrical coils, transformers, and other electrical components. They work in a manufacturing environment, ensuring that the coils are wound accurately and meet the required specifications.

1. Machine Operation

Wire Winders are responsible for setting up, operating, and maintaining wire winding machines. This includes loading the machine with wire, adjusting the machine settings, and monitoring the winding process to ensure that the coils are wound correctly.

- Set up and operate wire winding machines.

- Adjust machine settings to ensure coils are wound to the correct specifications.

- Monitor the winding process to ensure coils are wound correctly and meet quality standards.

2. Coil Inspection

After the coils have been wound, Wire Winders are responsible for inspecting them to ensure that they meet the required specifications. This includes checking the coil’s dimensions, resistance, and insulation.

- Inspect coils to ensure they meet the required specifications.

- Check coil dimensions.

- Check coil resistance.

- Check coil insulation.

3. Maintenance and Troubleshooting

Wire Winders are also responsible for maintaining and troubleshooting wire winding machines. This includes performing regular maintenance tasks, such as cleaning and lubricating the machine, and troubleshooting any problems that may arise.

- Perform regular maintenance tasks on wire winding machines.

- Clean and lubricate machines.

- Troubleshoot any problems that may arise.

4. Quality Control

Wire Winders are responsible for ensuring that the coils they produce meet the required quality standards. This includes following quality control procedures and inspecting coils to ensure that they are free of defects.

- Follow quality control procedures.

- Inspect coils to ensure they are free of defects.

- Identify and correct any defects.

Interview Tips

Preparing for a Wire Winder interview can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, goals, and values, as well as the specific requirements of the job. This information will help you tailor your answers to the interviewer’s questions and show that you are genuinely interested in the position.

- Visit the company’s website to learn about their history, mission, and products/services.

- Read industry news and articles to stay up-to-date on the latest trends.

- Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

2. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment. Avoid wearing clothing that is too revealing, too casual, or too formal.

- Choose a suit or dress pants and a button-down shirt or blouse.

- Make sure your clothes are clean, pressed, and fit well.

- Avoid wearing clothing that is too revealing, too casual, or too formal.

3. Be Punctual

Punctuality is important for any job interview, but it is especially important for a Wire Winder interview. This is because wire winding is a manufacturing process that is often time-sensitive. By being punctual, you will show the interviewer that you are reliable and that you respect their time.

- Plan your route to the interview in advance so that you can avoid any unexpected delays.

- Leave plenty of time for traffic and parking.

- If you are running late, call the interviewer to let them know.

4. Be Prepared to Answer Technical Questions

During your interview, you may be asked a number of technical questions about wire winding. These questions may cover topics such as wire winding machines, coil specifications, and quality control procedures.

- Review the job description carefully and make sure you understand the technical requirements of the position.

- Practice answering technical questions in advance.

- If you are not sure how to answer a question, don’t be afraid to ask the interviewer for clarification.

5. Be Enthusiastic and Positive

A positive attitude can go a long way in an interview. Show the interviewer that you are enthusiastic about the job and that you are eager to learn more about the company. Be friendly and approachable, and make eye contact with the interviewer.

- Smile and make eye contact with the interviewer.

- Be enthusiastic about the job and the company.

- Be positive and upbeat.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wire Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!