Feeling lost in a sea of interview questions? Landed that dream interview for Wire Winding Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wire Winding Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

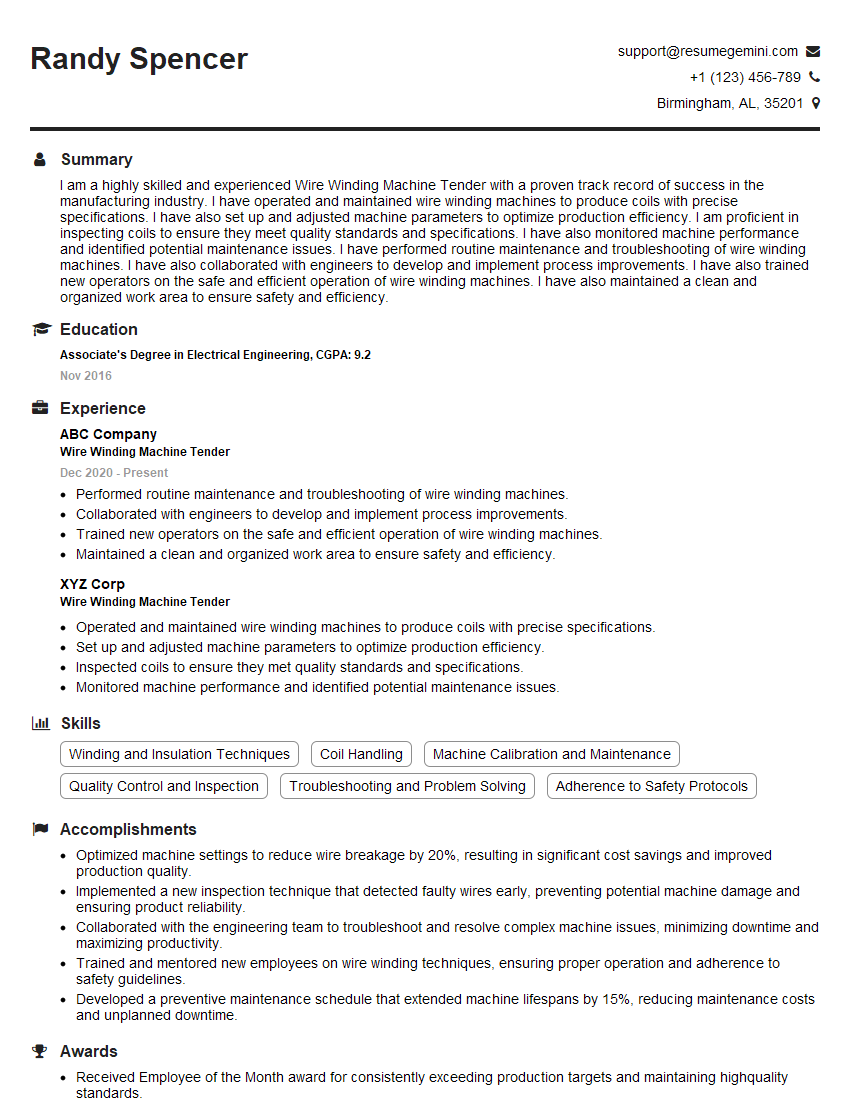

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Winding Machine Tender

1. Describe the process of wire winding on a CNC machine?

The process of wire winding on a CNC machine involves several steps:

- Machine Setup: The CNC machine is set up with the appropriate winding pattern, wire gauge, and tension settings.

- Wire Preparation: The wire is prepared by cutting it to the desired length and stripping the insulation at the ends.

- Wire Loading: The prepared wire is loaded onto the winding head of the CNC machine.

- Winding Process: The CNC machine automatically winds the wire onto the target surface, following the specified pattern and tension settings.

- Inspection: Once the winding process is complete, the coil is inspected for any defects or inconsistencies.

2. How do you determine the optimal wire tension for a given application?

Factors to Consider:

- Wire Material: Different wire materials have different tensile strengths and require specific tension settings.

- Winding Pattern: The winding pattern affects the stress distribution on the wire and determines the required tension.

- Target Surface: The surface material and shape can influence the tension required for secure winding.

Testing and Adjustment:

- Test Windings: Perform test windings at different tension settings to determine the optimal tension.

- Inspection: Examine the test windings for signs of over-tension (wire breakage) or under-tension (loose or uneven windings).

- Adjustment: Adjust the tension settings based on the inspection results to achieve the desired winding quality.

3. What are the common types of wire winding defects and how do you prevent them?

- Over-tension: Wires may break or become damaged when subjected to excessive tension.

- Under-tension: Loose or uneven windings can occur when the tension is insufficient.

- Contamination: Debris or moisture can accumulate on the wire, leading to insulation breakdown.

- Voids: Air pockets within the winding can cause overheating or arcing.

Prevention Measures:

- Proper Tension Control: Calibrate and monitor the tension settings to prevent over-tension or under-tension.

- Clean Environment: Maintain a clean work area to minimize contamination.

- Vacuum Impregnation: Applying a vacuum to the winding and impregnating it with a sealant can eliminate voids.

4. How do you troubleshoot and resolve winding machine malfunctions?

Troubleshooting involves a systematic approach:

- Identify Symptoms: Observe the machine behavior and identify any abnormal sounds, vibrations, or errors.

- Check Inputs: Verify that the power supply, air pressure, and wire feed are within specifications.

- Examine Machine Components: Inspect the winding head, tensioner, and other components for damage or wear.

- Consult Manuals: Refer to the machine’s manual for troubleshooting guides and error codes.

- Contact Manufacturer: If necessary, contact the machine manufacturer for technical support or spare parts.

5. Describe the safety precautions that should be followed when operating a wire winding machine?

- Wear Protective Gear: Gloves, safety glasses, and appropriate clothing should be worn to prevent injuries.

- Secure Loose Clothing: Loose clothing or jewelry can become entangled in the winding machine.

- Avoid Contact with Moving Parts: Keep hands and other body parts away from moving components.

- Check Emergency Stop: Ensure that the emergency stop button is easily accessible and functional.

- Maintain a Clean Workspace: Keep the work area clean to prevent tripping hazards and wire contamination.

6. Explain the principles of operation for a DC motor used in a wire winding machine?

DC Motor Operation:

- Electromagnetism: When current flows through a coil of wire, it creates a magnetic field.

- Rotating Armature: The armature, which is a rotating coil of wire, is placed within the magnetic field.

- Commutator: The commutator reverses the current direction in the armature, causing the armature to continue rotating.

In a Wire Winding Machine:

- Speed Control: The speed of the DC motor is controlled by adjusting the input voltage or by using a feedback loop with a tachometer.

- Torque: The torque of the motor is increased by increasing the current flowing through the armature.

7. How do you calculate the winding pitch of a wire coil?

Formula:

- Pitch = (Number of Slots * Slot Pitch) / Number of Poles

Parameters:

- Number of Slots: The number of slots in the stator or rotor where the wire is wound.

- Slot Pitch: The distance between the centers of two adjacent slots.

- Number of Poles: The number of magnetic poles in the machine.

8. Describe the different types of wire insulation used in wire winding applications?

- Enamel Insulation: A thin layer of enamel applied to the wire, providing electrical insulation and corrosion resistance.

- Polyurethane Insulation: A flexible and durable insulation that offers good dielectric strength and chemical resistance.

- Polyimide Insulation: A high-temperature insulation that can withstand extreme heat and harsh environments.

- Polyester Insulation: A cost-effective insulation with good electrical properties and temperature resistance.

9. How do you maintain the accuracy and precision of a wire winding machine?

- Calibration: Regularly calibrate the machine using traceable standards to ensure accurate winding.

- Tension Control: Maintain proper wire tension to prevent over-winding or under-winding.

- Cleanliness: Keep the machine clean to prevent wire tangles and contamination.

- Preventive Maintenance: Perform regular inspections and maintenance tasks to detect and address potential issues.

- Operator Training: Provide proper training to operators to ensure they understand the machine’s operation and maintenance procedures.

10. What techniques do you use to optimize the efficiency of a wire winding process?

- Process Optimization: Analyze the winding process to identify areas for improvement, such as reducing downtime or increasing winding speeds.

- Material Selection: Choose the right wire insulation and other materials to enhance winding efficiency and reliability.

- Automated Loading and Unloading: Implement automated systems to reduce manual labor and improve cycle times.

- Data Monitoring: Collect and analyze data to identify trends and potential areas for optimization.

- Continuous Improvement: Regularly evaluate and implement improvements to the winding process based on data analysis and feedback.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Winding Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Winding Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wire Winding Machine Tenders are responsible for operating and maintaining wire winding machines to produce electrical components. They may also perform other duties such as inspecting and testing products, maintaining inventory, and troubleshooting equipment.

1. Operating Wire Winding Machines

Wire Winding Machine Tenders operate wire winding machines to produce electrical components. They set up the machines, load the wire, and start the winding process. They monitor the machines during operation and adjust the controls as needed. They also inspect the finished products to ensure that they meet quality standards.

- Set up and operate wire winding machines.

- Load wire onto machines and start the winding process.

- Monitor machines during operation and adjust controls as needed.

- Inspect finished products to ensure that they meet quality standards.

2. Maintaining Wire Winding Machines

Wire Winding Machine Tenders are responsible for maintaining wire winding machines. They inspect the machines regularly and perform preventive maintenance tasks such as cleaning, lubricating, and adjusting components. They also troubleshoot and repair machines when necessary.

- Inspect wire winding machines regularly.

- Perform preventive maintenance tasks such as cleaning, lubricating, and adjusting components.

- Troubleshoot and repair machines when necessary.

3. Inspecting and Testing Products

Wire Winding Machine Tenders inspect and test finished products to ensure that they meet quality standards. They use a variety of testing equipment to check for defects such as shorts, opens, and insulation problems.

- Inspect finished products for defects such as shorts, opens, and insulation problems.

- Use a variety of testing equipment to check for defects.

4. Maintaining Inventory

Wire Winding Machine Tenders maintain inventory of wire and other materials used in the winding process. They track inventory levels and place orders for new materials when necessary.

- Maintain inventory of wire and other materials.

- Track inventory levels and place orders for new materials when necessary.

5. Troubleshooting Equipment

Wire Winding Machine Tenders troubleshoot and repair equipment when necessary. They use their knowledge of electrical systems and mechanical components to identify and fix problems.

- Troubleshoot and repair equipment when necessary.

- Identify and fix problems with electrical systems and mechanical components.

Interview Tips

Preparing for an interview for a Wire Winding Machine Tender position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on its website, social media pages, and Glassdoor.

- Visit the company’s website to learn about its history, products, and services.

- Read the job description carefully.

- Check out the company’s social media pages to get a sense of its culture.

- Read reviews of the company on Glassdoor.

2. Practice Answering Common Interview Questions

There are certain questions that are commonly asked in interviews for Wire Winding Machine Tender positions. By preparing answers to these questions, you can increase your confidence and fluency during the interview.

- Tell me about your experience with wire winding machines.

- What are your strengths and weaknesses as a Wire Winding Machine Tender?

- Why are you interested in this position?

- What are your salary expectations?

- Do you have any questions for me?

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire.

- Arrive on time for your interview.

4. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and be enthusiastic during your interview. The interviewer wants to get to know the real you and see if you are a good fit for the position. Be honest about your experience and skills, and don’t be afraid to show your passion for the work.

- Be yourself and be enthusiastic.

- Be honest about your experience and skills.

- Show your passion for the work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wire Winding Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.