Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wood Barrel Reconditioner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

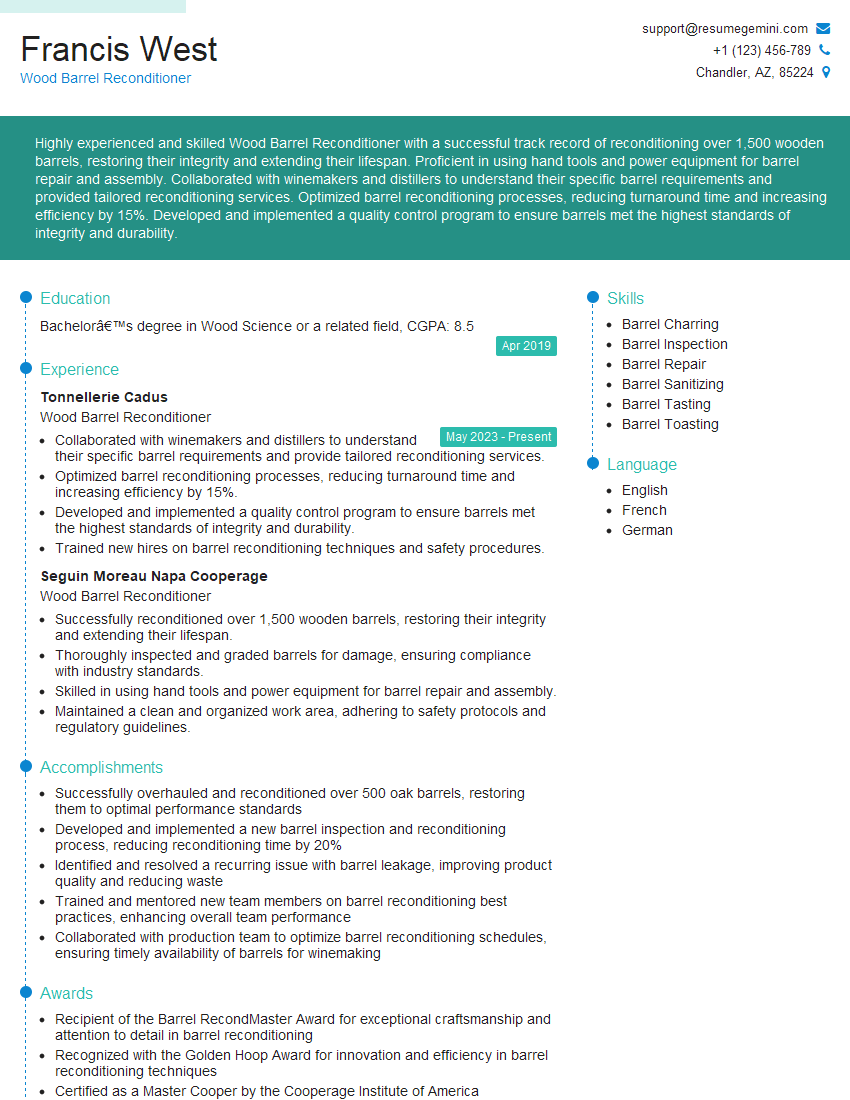

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Barrel Reconditioner

1. Describe the process of reconditioning a wooden barrel?

The process of reconditioning a wooden barrel involves several steps:

- Inspection: The barrel is thoroughly inspected to assess its condition and identify any damage or leaks.

- Disassembly: The barrel is disassembled into its individual components, including the head, hoops, and staves.

- Cleaning: The components are cleaned using a specialized cleaning solution to remove any impurities or contaminants.

- Repair: Any damaged staves or hoops are repaired or replaced using traditional techniques, such as barrel making and cooperage.

- Reassembly: The barrel is reassembled and secured with new hoops.

- Leak testing: The barrel is tested for leaks by filling it with water or a pressure testing solution.

- Finishing: The barrel may be stained, lacquered, or treated with a sealant to protect and enhance its appearance.

2. What are the different types of wood used in barrel making, and what are their properties?

Oak

- Durable and strong

- High tannin content contributes to wine’s flavor and aroma

- Used for aging whiskey, wine, beer, and spirits

Acacia

- Hard and long-lasting

- Imparts a smoky and spicy flavor to spirits

- Used for aging tequila, mezcal, and rum

Chestnut

- Soft and porous

- Absorbs more liquid than other woods

- Used for aging wine, beer, and spirits

3. Explain the importance of grain orientation when selecting staves for barrel making?

Grain orientation affects the barrel’s strength and durability. When the staves are oriented correctly, the grain runs parallel to the hoops, providing maximum support against the pressure of the liquid inside the barrel.

4. Describe the role of toasting in barrel aging?

Toasting involves heating the interior of the barrel to caramelize the wood sugars. This process:

- Enhances the flavor and aroma of the aged beverage

- Reduces tannins and astringency

- Creates micropores that allow for oxygen exchange, which influences the aging process

5. What are the common defects found in wooden barrels and how do you address them?

Common defects include:

- Leaks: Caused by damaged staves or improper assembly; repaired by replacing staves or tightening hoops

- Bulges: Result from excessive pressure; addressed by releasing pressure or replacing damaged staves

- Cracks: Occurs due to drying or mishandling; can be repaired with glue or by replacing the stave

- Mold or fungus: Caused by moisture or improper storage; treated with antifungal solutions and proper drying

6. Describe the safety protocols you follow when working with wood barrels?

- Wear appropriate protective gear, such as gloves, safety glasses, and a dust mask

- Inspect barrels thoroughly before handling to identify potential hazards

- Use proper lifting techniques to avoid back injuries

- Follow established procedures for storing and transporting barrels

7. Explain the process of rejuvenating a barrel that has been used for aging?

Rejuvenation involves:

- Removing old wine or spirits

- Cleaning the barrel to remove any residue

- Inspecting for damage or leaks

- Re-toasting the barrel to restore its flavor profile

- Testing the barrel for proper functionality

8. Describe the different methods used to seal wooden barrels?

- Waxing: Applying beeswax or other natural waxes to create a barrier against moisture

- Epoxy: Using food-grade epoxy to seal cracks or leaks

- Pitch: A traditional sealant made from pine resin, used to fill gaps and prevent leaks

9. How do you determine the size and capacity of a wooden barrel?

The size and capacity of a barrel are typically measured using:

- Head diameter: Measured across the top or bottom of the barrel

- Bulge: The widest part of the barrel

- Height: Measured from the top edge of the head to the bottom edge of the chime

10. What are the environmental factors that can affect the longevity of wooden barrels?

- Humidity: High humidity can cause swelling and weaken the wood

- Temperature: Extreme temperatures can cause the wood to expand or contract

- UV exposure: Sunlight can damage the wood’s surface and finish

- Moisture: Excessive moisture can lead to mold, fungus, and rot

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Barrel Reconditioner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Barrel Reconditioner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wood Barrel Reconditioner’s role is to restore and maintain the quality of wooden barrels used in various industries, such as winemaking and distilling. Their primary responsibilities include:

1. Barrel Inspection and Assessment

Thoroughly inspect barrels to evaluate their condition, identify any damages, and assess the extent of repairs needed.

- Examine the wood for cracks, splinters, or any signs of rot.

- Check the hoops for rust, damage, or loose fittings.

2. Barrel Disassembly and Cleaning

Disassemble the barrel into its individual components, including staves, hoops, and heads.

- Use specialized tools to remove the hoops and disassemble the barrel.

- Thoroughly clean all components with water and sanitizing agents.

3. Barrel Repair and Reconditioning

Repair damaged staves by planing, sanding, or replacing them.

- Replace rusted or damaged hoops with new ones.

- Reassemble the barrel and tighten the hoops to ensure a secure fit.

4. Barrel Testing and Quality Control

Test the reconditioned barrels to ensure they meet industry standards for strength and integrity.

- Perform pressure tests to check for leaks or weaknesses.

- Inspect the barrels for any defects or imperfections.

Interview Tips

Preparing for an interview is crucial for a successful outcome. Here are some tips to help you ace your interview for a Wood Barrel Reconditioner position:

1. Research the Company and Industry

- Learn about the company’s history, values, and products.

- Research the winemaking or distilling industry to understand their specific needs and requirements.

- Look up the job description carefully and identify the key responsibilities and qualifications.

2. Highlight Your Skills and Experience

- Emphasize your experience in wood barrel reconditioning, including any specific techniques or equipment you have worked with.

- Showcase your knowledge of barrel construction, repair methods, and quality control standards.

- Provide examples of successful barrel reconditioning projects you have completed.

3. Demonstrate Your Passion and Attention to Detail

- Express your enthusiasm for the role and explain why you are tertarik in barrel reconditioning.

- Highlight your attention to detail and ability to work precisely and meticulously.

- Share examples of your commitment to quality and ensuring that reconditioned barrels meet industry regulations.

4. Prepare Questions to Ask

- Prepare thoughtful questions to ask the interviewer, such as the company’s production capacity and the types of barrels they recondition.

- Asking questions shows your interest and engagement and gives you an opportunity to gather more information about the role and company.

- Example questions: “What is the company’s policy on barrel maintenance and replacement?” or “What are the key performance indicators for this position?”

5. Dress Professionally and Arrive on Time

- First impressions matter, so dress professionally and arrive at the interview venue on time.

- This not only shows respect for the interviewer but also indicates your punctuality and professionalism.

- It is also important to maintain proper body language and eye contact during the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wood Barrel Reconditioner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.