Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wood Bucker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

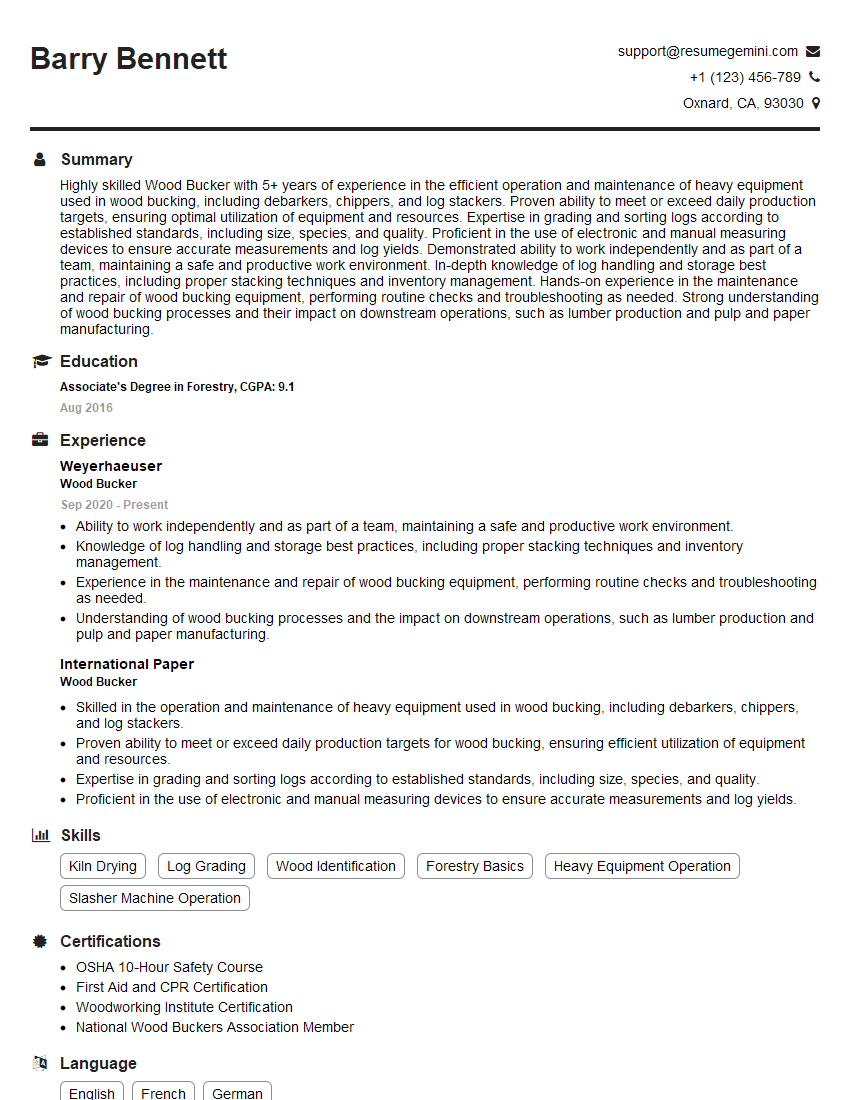

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Bucker

1. What is the process of wood bucking?

Wood bucking is the process of cutting felled trees into smaller, more manageable pieces called logs or billets. It involves removing branches, trimming the ends, and cutting the trunk into specific lengths.

2. What are the different types of wood bucking machines?

Manual Bucking

- Bucking bars (with or without chains)

- Bow saws

Semi-Automatic Bucking

- Hydraulic bucking machines

- Pneumatic bucking machines

Fully-Automatic Bucking

- Cut-to-length machines

- Processor heads

3. What factors should be considered when selecting a wood bucking machine?

- Type of wood being cut

- Log diameter and length

- Production volume

- Cost and availability

4. How do you ensure safety when operating a wood bucking machine?

- Wear proper safety gear (gloves, chaps, safety glasses)

- Inspect the machine before use

- Clear the work area of debris

- Follow manufacturer’s instructions and guidelines

5. What are the common problems that can occur when wood bucking?

- Chainsaw kickback

- Branch pinching

- Log rolling

- Machine breakdowns

6. How do you troubleshoot common wood bucking problems?

Chainsaw Kickback

- Inspect chainsaw for damaged or loose chain

- Ensure proper cutting technique

Branch Pinching

- Cut branches close to the trunk

- Use a wedges to prevent pinching

Log Rolling

- Use chocks or ramps to secure logs

- Stabilize logs with chains or cables

7. Describe your experience in wood bucking operations.

- Worked as a wood bucker for [Company Name] for 5 years

- Operated various types of wood bucking machines

- Consistently exceeded production targets and maintained high quality standards

8. What are your strengths and weaknesses as a wood bucker?

Strengths

- Strong physical abilities

- Proficient in operating wood bucking machines

- Excellent safety record

Weaknesses

- Limited experience in automated wood bucking systems

- Not certified in advanced wood bucking techniques

9. How do you stay up-to-date with the latest wood bucking technologies and practices?

- Attend industry conferences and workshops

- Read trade publications and online forums

- Consult with equipment manufacturers and suppliers

10. What are your career goals as a wood bucker?

- Become a certified wood bucking instructor

- Train and supervise new wood buckers

- Contribute to the development of innovative wood bucking techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Bucker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Bucker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Buckers are responsible for operating and maintaining machines that cut and shape raw logs into usable lumber. The primary job duties include:

1. Machine Operation

Wood Buckers operate various machines, such as sawmills, planers, and edgers, to cut and shape logs into lumber. They must be able to operate the machines safely and efficiently, and to make adjustments as needed to ensure that the lumber is cut to the correct specifications.

- Set up and operate sawmills, planers, and edgers

- Feed logs into the machines and ensure that they are properly aligned

- Monitor the machines during operation and make adjustments as needed

- Unload lumber from the machines and stack it properly

2. Machine Maintenance

Wood Buckers are responsible for maintaining the machines they operate. This includes cleaning, lubricating, and repairing the machines as needed. They must be able to identify potential problems and take steps to prevent them from occurring.

- Clean and lubricate machines on a regular basis

- Inspect machines for potential problems and make repairs as needed

- Replace worn or damaged parts

- Keep a record of all maintenance activities

3. Quality Control

Wood Buckers are responsible for ensuring that the lumber they produce meets the required quality standards. They must be able to inspect lumber for defects, such as knots, cracks, and splits. They must also be able to make adjustments to the machines to ensure that the lumber is cut to the correct specifications.

- Inspect lumber for defects

- Make adjustments to the machines to ensure that the lumber is cut to the correct specifications

- Reject lumber that does not meet the required quality standards

4. Safety

Wood Buckers work in a hazardous environment, and they must be aware of the potential hazards and take steps to avoid them. They must be able to operate machines safely, and they must be able to wear appropriate safety gear.

- Operate machines safely

- Wear appropriate safety gear

- Follow all safety regulations

- Report any unsafe conditions

Interview Tips

To prepare for an interview for a Wood Bucker position, you should familiarize yourself with the key job responsibilities and qualifications. You should also practice answering common interview questions, such as:

1. Tell me about your experience operating and maintaining woodworking machines.

In your answer, be sure to highlight your skills and experience in operating and maintaining woodworking machines. You should mention the specific types of machines you have operated, and the tasks you have performed, such as setting up, operating, and maintaining the machines.

- Example Outline:

- I have over 5 years of experience operating and maintaining woodworking machines, including sawmills, planers, and edgers.

- In my previous role, I was responsible for setting up, operating, and maintaining all of the woodworking machines in the shop.

- I have a strong understanding of the principles of woodworking, and I am able to operate and maintain the machines safely and efficiently.

- I am also able to identify potential problems and take steps to prevent them from occurring.

2. What are your quality control standards?

In your answer, be sure to explain your understanding of quality control standards, and how you ensure that the lumber you produce meets those standards. You should mention the specific steps you take to inspect lumber for defects, and the actions you take to correct any defects that are found.

- Example Outline:

- I understand the importance of quality control, and I am committed to producing lumber that meets the highest standards.

- I inspect every piece of lumber that I produce for defects, such as knots, cracks, and splits.

- If I find any defects, I take steps to correct them, such as cutting out the knot or repairing the crack.

- I also make sure to follow all of the quality control procedures that are in place at my workplace.

3. What are the safety hazards associated with working with woodworking machines?

In your answer, be sure to identify the potential hazards associated with working with woodworking machines, and explain the steps you take to avoid those hazards. You should mention the specific safety gear you wear, and the safety procedures you follow.

- Example Outline:

- The potential hazards associated with working with woodworking machines include cuts, lacerations, amputations, and eye injuries.

- To avoid these hazards, I always wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- I also follow all of the safety procedures that are in place at my workplace, such as never operating a machine without proper training, and never leaving a machine running unattended.

4. What is your experience with teamwork?

In your answer, be sure to highlight your experience working as part of a team, and the contributions you have made to the team’s success. You should mention specific examples of times when you have worked effectively with others to achieve a common goal.

- Example Outline:

- I have a strong track record of working effectively within a team environment. In my previous role, I was part of a team that was responsible for producing high-quality lumber for a variety of customers.

- I was responsible for operating and maintaining the sawmill, and I worked closely with other team members to ensure that the lumber was produced to the correct specifications and met the customer’s requirements.

- I am a team player, and I am always willing to do my part to contribute to the team’s success.

5. Why are you interested in this position?

In your answer, be sure to express your interest in the position and the company. You should also explain why you are qualified for the position, and how your skills and experience can benefit the company.

- Example Outline:

- I am interested in this position because I am passionate about woodworking, and I am eager to use my skills and experience to contribute to your company’s success.

- I have over 5 years of experience operating and maintaining woodworking machines, and I have a strong understanding of the principles of woodworking.

- I am confident that I can use my skills and experience to help your company produce high-quality lumber and meet the needs of your customers.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wood Bucker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.