Are you gearing up for a career in Wood Carving Lathe Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wood Carving Lathe Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

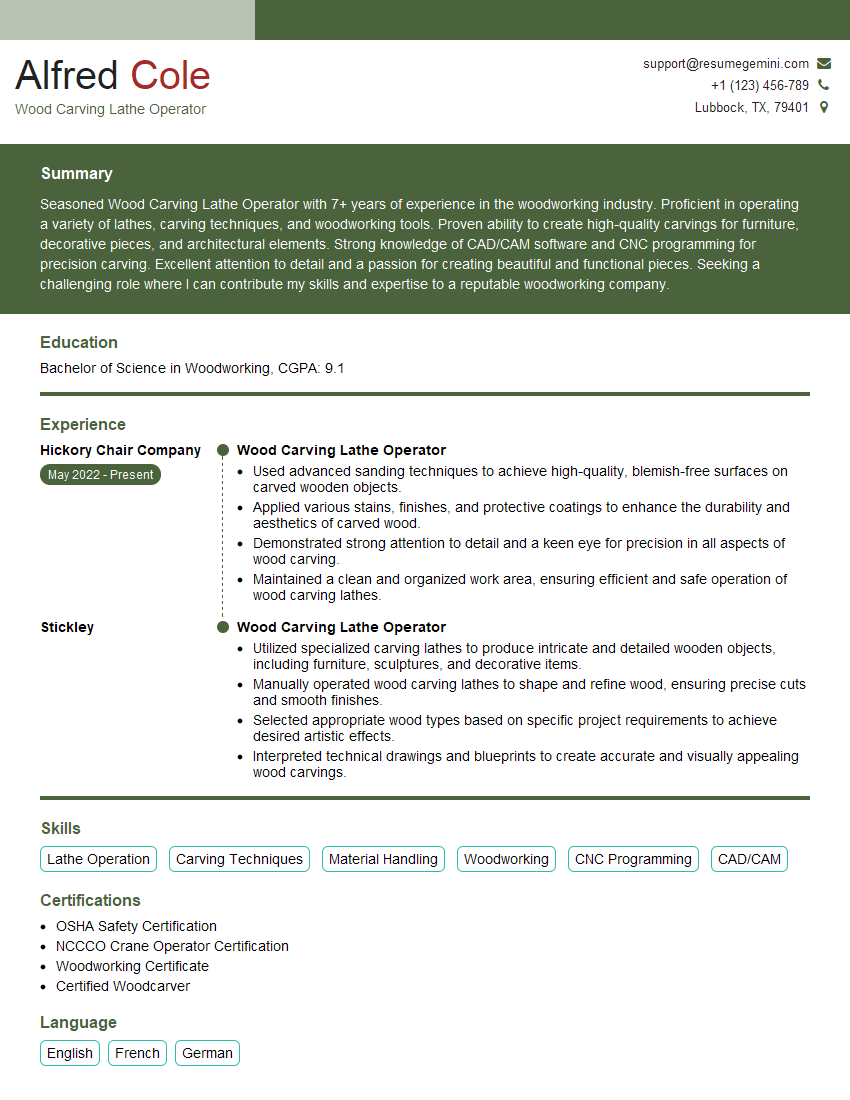

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Carving Lathe Operator

1. Could you please explain the types of woodcarving lathes and their specific uses?

Woodcarving lathes can be categorized into three main types:

- Benchtop Lathes: Compact and ideal for small-scale projects, perfect for hobbyists and beginners

- Midi Lathes: Offer more power and capacity than benchtop lathes, suitable for intermediate woodworkers

- Floor-standing Lathes: Industrial-grade lathes with robust construction, designed for heavy-duty work and large projects

2. How do you go about selecting the appropriate cutting tools for a specific woodcarving project?

Selecting the right cutting tools is crucial for efficient and precise woodcarving:

- Consider the wood type: Different woods require different cutting tools due to their hardness and grain

- Choose the correct grind: The grind angle of the tool determines the sharpness and durability of the edge

- Use specialized tools for specific cuts: Gouges, chisels, and scrapers each serve distinct functions

3. Describe the safety precautions you strictly adhere to when operating a woodcarving lathe.

Adhering to safety protocols is paramount for a woodcarving lathe operator:

- Wear appropriate protective gear: Eye protection, gloves, and a dust mask are essential

- Securely mount the workpiece: Improperly mounted workpieces can become projectiles

- Inspect tools and equipment regularly: Check for damage or defects before each use

- Maintain a clean work area: Clear away shavings and sawdust to prevent tripping hazards

- Never operate the lathe under the influence of substances: Alcohol or drugs can impair judgment and coordination

4. How do you determine the correct speed settings for a woodcarving lathe based on the project requirements?

Selecting the appropriate speed is crucial for achieving the desired results:

- Consider the wood type: Softer woods require lower speeds, while harder woods can handle higher speeds

- Factor in the size of the workpiece: Larger workpieces require lower speeds for stability

- Adjust the speed gradually: Avoid abrupt changes that can cause the workpiece to fly off the lathe

5. Explain the techniques you employ to achieve smooth and precise cuts while using a woodcarving lathe.

Achieving smooth and precise cuts requires a combination of techniques:

- Sharpen tools regularly: Dull tools produce rough cuts

- Maintain a steady hand: Avoid jerky movements that can create uneven cuts

- Use a light touch: Excessive pressure can cause the tool to dig into the wood

- Follow the grain: Carving with the grain prevents tearing and splintering

6. How do you go about troubleshooting common issues that arise while operating a woodcarving lathe?

Troubleshooting is essential for resolving issues and ensuring smooth operation:

- Excessive vibration: Check for unbalanced workpieces, loose mountings, or dull tools

- Burning of the wood: Reduce speed, use sharper tools, or apply a lubricant

- Chattering: Adjust speed, use a finer grit tool, or check for loose tool holders

- Workpiece flying off the lathe: Ensure proper mounting, check for warped workpieces, and use a tailstock center

7. Can you describe your experience in using different types of woodcarving lathe attachments, such as chucks, faceplates, and indexing heads?

Experience with attachments enhances versatility:

- Chucks: Hold cylindrical workpieces securely for precise turning

- Faceplates: Mount flat or irregular-shaped workpieces for carving bowls and platters

- Indexing heads: Allow for precise angle cutting and repetitive cuts

8. How do you maintain and calibrate a woodcarving lathe to ensure optimal performance and accuracy?

Regular maintenance is crucial for precision:

- Lubricate moving parts: Reduce friction and prevent wear

- Clean and remove sawdust: Prevent buildup and ensure smooth operation

- Calibrate the lathe: Ensure accurate measurements and tool alignment

9. Can you explain the different types of finishes that can be applied to woodcarvings and the techniques used to achieve them?

Understanding finishes enhances presentation:

- Oil finishes: Penetrate the wood, enhancing grain and protecting against moisture

- Wax finishes: Create a protective layer, adding shine and repelling water

- Lacquer finishes: Durable and glossy, providing a hard protective coating

10. How do you adapt your woodcarving skills to different project requirements and customer preferences?

Adaptability is key to customer satisfaction:

- Understanding customer needs: Discuss design, wood selection, and finish preferences

- Adjusting techniques: Alter speed, tool selection, and cutting styles based on project specifications

- Experimenting with new approaches: Explore innovative methods to achieve unique effects

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Carving Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Carving Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Carving Lathe Operator is responsible for carving wood using a lathe machine. They use a variety of chisels, gouges, and other tools to create intricate designs on wood. This role requires a strong understanding of wood carving techniques and the ability to operate a lathe machine safely and efficiently.

1. Operate lathe machine

The Wood Carving Lathe Operator is responsible for operating the lathe machine safely and efficiently. This includes setting up the machine, loading and unloading the wood, and adjusting the speed and feed settings. The operator must also be able to identify and correct any problems that may occur with the machine.

- Follow safety procedures when operating the lathe machine

- Set up the lathe machine according to the desired specifications

- Load and unload the wood from the lathe machine

- Adjust the speed and feed settings of the lathe machine

- Identify and correct any problems that may occur with the lathe machine

2. Carve wood using a variety of chisels and gouges

The Wood Carving Lathe Operator uses a variety of chisels and gouges to carve designs into wood. The operator must be able to use these tools effectively and safely to create intricate designs. The operator must also be able to select the appropriate chisel or gouge for the desired result.

- Select the appropriate chisel or gouge for the desired result

- Use chisels and gouges to carve designs into wood

- Use a variety of techniques to create different effects

- Carve designs that are both intricate and visually appealing

3. Apply finishes to protect and enhance the wood

The Wood Carving Lathe Operator may also be responsible for applying finishes to the wood to protect and enhance the wood. This may include applying a stain, varnish, or paint. The operator must be able to follow the manufacturer’s instructions for applying the finish and must be able to achieve a high-quality finish.

- Apply finishes to protect and enhance the wood

- Follow the manufacturer’s instructions for applying the finish

- Achieve a high-quality finish

- Protect the wood from damage and wear

4. Maintain the lathe machine and work area

The Wood Carving Lathe Operator is responsible for maintaining the lathe machine and work area. This includes cleaning the machine, lubricating the moving parts, and making minor repairs. The operator must also be able to identify and correct any potential safety hazards in the work area.

- Clean the lathe machine and work area

- Lubricate the moving parts of the lathe machine

- Make minor repairs to the lathe machine

- Identify and correct any potential safety hazards in the work area

Interview Tips

Here are some interview tips for Wood Carving Lathe Operator candidates:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on its website, LinkedIn page, and Glassdoor. You can also find information about the position in the job description.

- Visit the company website

- Research the company on LinkedIn

- Read the job description carefully

- Read reviews of the company on Glassdoor

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions beforehand so that you can deliver clear and concise responses. You can practice with a friend or family member, or you can record yourself answering the questions and then listen back to your answers.

- Practice answering common interview questions

- Use the STAR method to answer questions

- Be clear and concise in your responses

- Record yourself answering questions and then listen back to your answers

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Wood Carving Lathe Operator. Be prepared to talk about your experience operating a lathe machine, using chisels and gouges, and applying finishes. You should also be prepared to talk about your skills in safety, maintenance, and troubleshooting.

- Be prepared to talk about your experience operating a lathe machine

- Be prepared to talk about your experience using chisels and gouges

- Be prepared to talk about your experience applying finishes

- Be prepared to talk about your skills in safety, maintenance, and troubleshooting

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic and positive about the position. Be sure to show your passion for wood carving and your desire to learn and grow in the role. You should also be positive about the company and the opportunity to work there.

- Be enthusiastic and positive about the position

- Show your passion for wood carving

- Express your desire to learn and grow in the role

- Be positive about the company and the opportunity to work there

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Carving Lathe Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!