Are you gearing up for an interview for a Wood Carving Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wood Carving Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

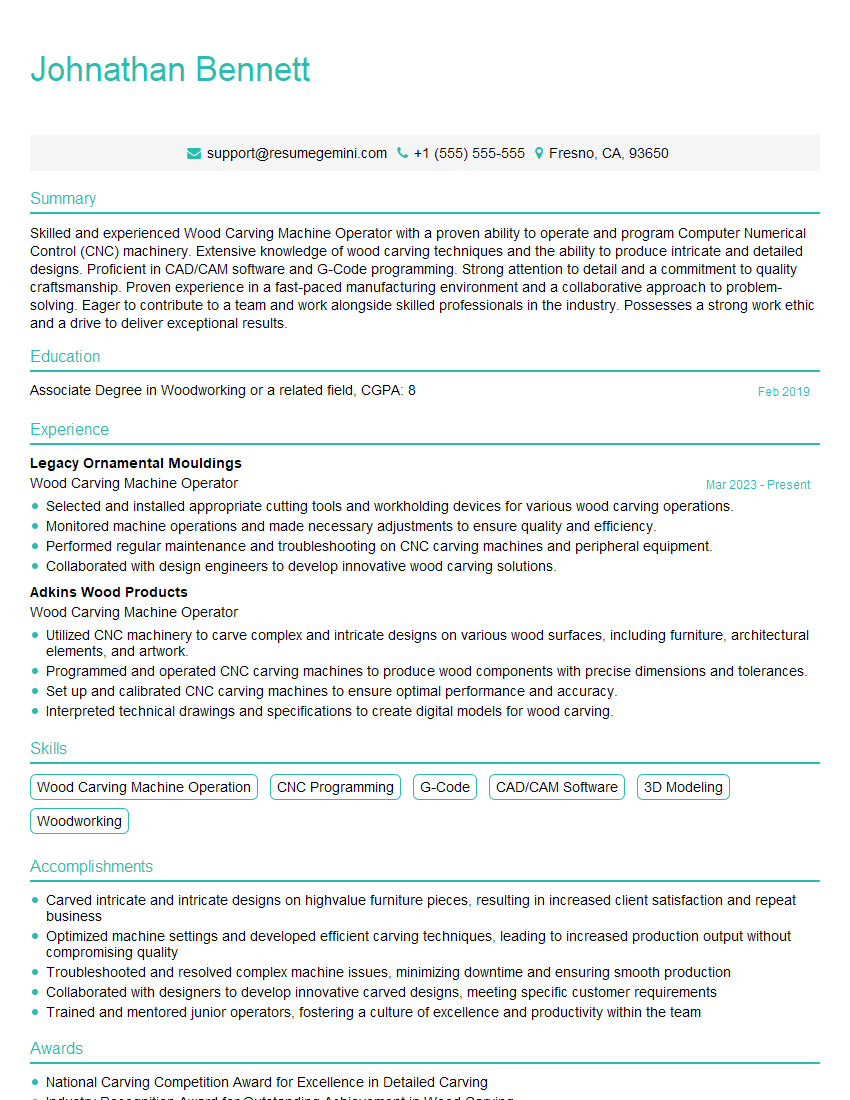

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Carving Machine Operator

1. How would you set up and operate a wood carving machine?

To set up and operate a wood carving machine:

- Ensure the machine is securely fastened to a solid surface.

- Select the appropriate cutting tool and install it into the machine.

- Secure the workpiece to the machine’s worktable.

- Set the machine’s cutting parameters, including speed, depth, and feed rate.

- Start the machine and monitor the cutting process.

2. What are the different types of wood carving machine cutters, and how do you choose the right one for a particular job?

Types of wood carving machine cutters:

- Ball nose cutters: For creating smooth, rounded cuts.

- V-cutters: For creating V-shaped cuts.

- Flat end cutters: For creating flat cuts.

- Tapered cutters: For creating tapered cuts.

Choosing the right cutter:

- Consider the type of cut you want to make.

- Select a cutter with the appropriate diameter and shape.

- Match the cutter to the material you are carving.

3. How do you maintain a wood carving machine?

To maintain a wood carving machine:

- Clean the machine regularly to remove dust and debris.

- Inspect the cutting tools for wear and tear.

- Tighten loose screws and bolts.

- Lubricate moving parts.

- Follow the manufacturer’s maintenance recommendations.

4. How do you troubleshoot common wood carving machine problems?

To troubleshoot common wood carving machine problems:

- Check the power supply and ensure the machine is plugged in.

- Inspect the cutting tool for damage or wear.

- Adjust the cutting parameters, such as speed, depth, and feed rate.

- Check for loose screws or bolts.

- Refer to the manufacturer’s troubleshooting guide.

5. What safety precautions should be taken when operating a wood carving machine?

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Secure the workpiece firmly to the worktable.

- Keep hands away from the cutting area.

- Never operate the machine under the influence of drugs or alcohol.

- Follow all manufacturer’s safety instructions.

6. What techniques can be used to create different effects with a wood carving machine?

To create different effects with a wood carving machine:

- Use different types of cutting tools.

- Vary the cutting parameters, such as speed, depth, and feed rate.

- Experiment with different carving techniques, such as plunge cutting, relief carving, and intaglio carving.

- Use jigs and fixtures to achieve precise cuts.

7. How do you use a wood carving machine to create a specific design?

To use a wood carving machine to create a specific design:

- Import the design into the machine’s software.

- Select the appropriate cutting tool and cutting parameters.

- Secure the workpiece to the worktable.

- Start the carving process and monitor the progress.

- Make adjustments as needed to achieve the desired results.

8. What is the difference between a CNC wood carving machine and a manual wood carving machine?

CNC wood carving machine:

- Computer-controlled.

- High precision and accuracy.

- Can carve complex designs.

Manual wood carving machine:

- Operated by hand.

- Less precise and accurate than CNC machines.

- More suitable for simple designs.

9. What are the advantages of using a wood carving machine over hand carving?

- Faster and more efficient.

- More precise and accurate.

- Can create complex designs.

- Less physically demanding.

10. What are your career goals as a Wood Carving Machine Operator?

My career goals as a Wood Carving Machine Operator are:

- To become a highly skilled and experienced operator.

- To contribute to the production of high-quality wood carvings.

- To advance my skills and knowledge of wood carving machines.

- To eventually become a supervisor or manager in the wood carving industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Carving Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Carving Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wood Carving Machine Operator is responsible for operating and maintaining computer numerical controlled (CNC) wood carving machines to produce intricate and precise wooden objects.

1. Machine Operation

intro paragraph

- Set up and operate CNC wood carving machines according to specifications.

- Load and unload raw materials and finished products.

- Monitor and adjust machine settings to ensure optimal performance.

- Inspect finished products for quality and accuracy.

2. Maintenance and Troubleshooting

intro paragraph

- Perform routine maintenance on CNC wood carving machines to prevent breakdowns.

- Troubleshoot and resolve machine malfunctions efficiently.

- Lubricate and clean machine components regularly.

- Report any maintenance or repair needs to superiors.

3. Software and Design

intro paragraph

- Create and edit design files using computer-aided design (CAD) software.

- Program CNC wood carving machines using G-code or other programming languages.

- Convert 2D and 3D designs into machine-readable formats.

- Stay up-to-date on software updates and industry best practices.

4. Safety and Compliance

intro paragraph

- Follow all safety protocols and wear appropriate personal protective equipment.

- Maintain a clean and organized work area.

- Dispose of waste materials properly.

- Adhere to environmental regulations and standards.

Interview Tips

Preparing for a Wood Carving Machine Operator interview requires a combination of technical knowledge, industry familiarity, and strong communication skills. Here are some tips to help you ace the interview:

1. Research the Company and the Industry

Familiarize yourself with the company’s background, products or services, and industry trends. This demonstrates your interest and enthusiasm for the role.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Attend industry events if possible.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining CNC wood carving machines. Quantify your experience whenever possible.

- Discuss specific machine models you have operated.

- Describe troubleshooting and repair procedures you have successfully performed.

- Showcase your knowledge of CAD software and programming languages.

3. Demonstrate Your Attention to Detail

Wood carving requires precision and accuracy. Highlight your ability to work meticulously and ensure the highest quality standards.

- Provide examples of projects where you achieved exceptional results.

- Discuss your quality control procedures.

- Emphasize your commitment to safety and compliance.

4. Practice Your Communication Skills

Be prepared to clearly articulate your technical knowledge and experience. Practice answering common interview questions in a concise and engaging manner.

- Prepare a brief overview of your skills and qualifications

- Role-play interview scenarios with a friend or family member.

- Seek feedback on your communication style and delivery.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Carving Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.