Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wood Coater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

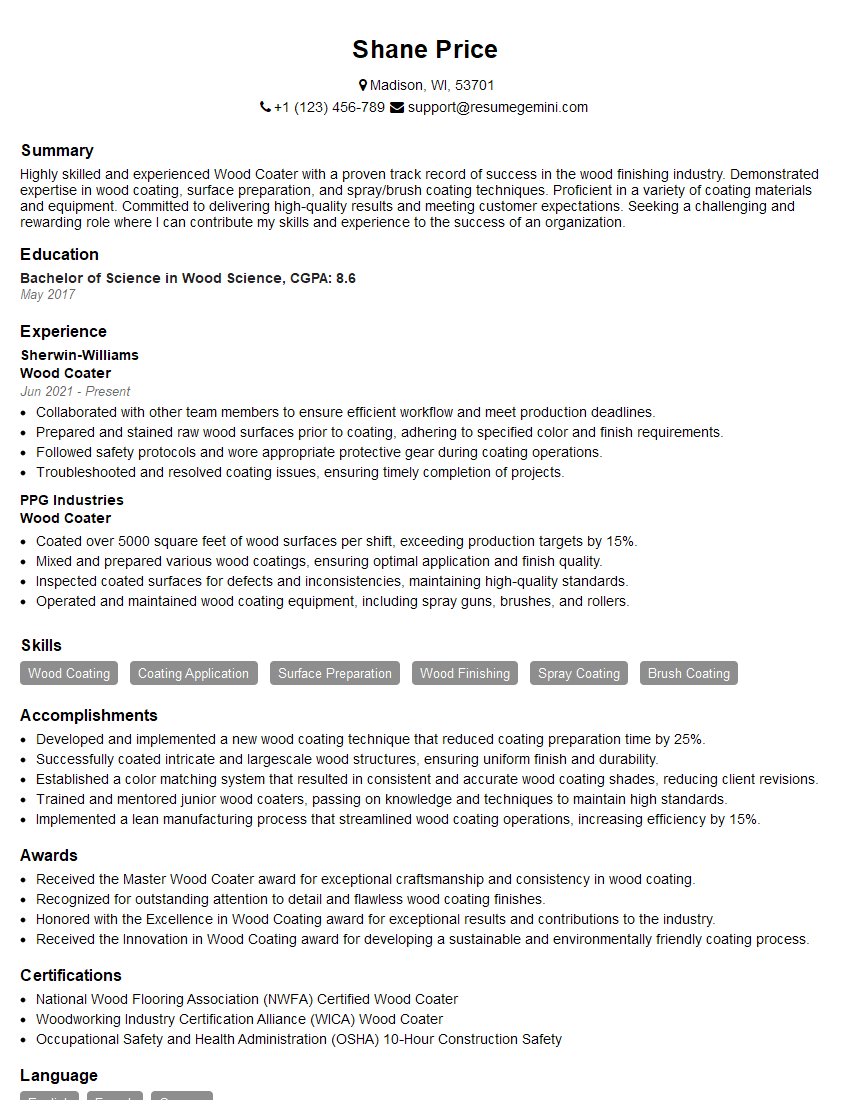

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Coater

1. Describe the process of wood coating in detail.

The process of wood coating involves several steps:

- Preparation: The wood surface is sanded to remove any imperfections and smoothed to ensure proper adhesion.

- Application: The coating material is applied to the wood surface using a brush, roller, or sprayer. Multiple coats may be required depending on the desired finish.

- Drying: The coating is allowed to dry and cure completely. This process can take several hours or days.

- Sanding and Polishing: After drying, the surface is sanded lightly to remove any raised wood fibers and then polished to achieve a smooth and glossy finish.

2. What factors should be considered when selecting a wood coating?

Substrate compatibility:

- The type of wood and its porosity should be considered to ensure the coating adheres properly.

- The intended use of the wood (e.g., indoor vs. outdoor) also affects the coating selection.

Desired finish:

- The gloss level, color, and texture of the finish should match the desired aesthetic.

Environmental factors:

- The coating should be resistant to UV rays, moisture, and other environmental conditions.

Safety and regulations:

- The coating should meet VOC (volatile organic compound) regulations and other safety standards.

3. Explain the difference between a penetrating finish and a surface coating.

- Penetrating finishes: Soak into the wood’s pores, providing protection from the inside out. They enhance the wood’s natural grain and color.

- Surface coatings: Form a protective layer on top of the wood surface. They provide excellent protection against moisture and wear but may alter the wood’s appearance.

4. What are the common defects that can occur during wood coating and how can they be prevented?

- Runs and Sags: Caused by applying too much coating or using a coating with low viscosity. Prevented by using a proper viscosity coating and applying thin, even layers.

- Bubbles: Entrapment of air during application. Prevented by degassing the coating before applying and ensuring proper mixing.

- Orange peel: A rough, textured surface. Caused by applying the coating too thickly or using a coating with high surface tension. Prevented by thinning the coating and applying multiple thin layers.

- Brush marks: Visible streaks left behind by the brush. Prevented by using a high-quality brush and applying the coating in the direction of the wood grain.

5. Describe the equipment used in the wood coating process and their functions.

- Sandpaper/Sander: Removes imperfections and smooths the wood surface for better coating adhesion.

- Brush/Roller/Sprayer: Applies the coating material evenly to the wood surface.

- Coating Mixing Equipment: Ensures proper mixing of the coating components.

- Drying Oven/Cabinet: Accelerates the drying and curing process under controlled temperature and humidity conditions.

- Safety Gear (Gloves/Mask/Goggles): Protects the operator from exposure to chemicals and dust.

6. Explain the importance of maintaining the viscosity of the coating material.

- Proper viscosity ensures the coating can be applied easily and evenly.

- Viscosity affects the flow and leveling of the coating, influencing the final finish.

- Viscosity can be adjusted by adding solvents or thinners.

7. Describe the techniques used to achieve specific wood finishes, such as distressing, antiquing, or glazing.

- Distressing: Creating an aged or weathered appearance by sanding or brushing the wood surface to remove the top layer.

- Antiquing: Applying a dark glaze to the wood, followed by wiping it off to create a patina effect.

- Glazing: Applying a semi-transparent glaze over the wood to enhance the grain and add color while preserving the natural texture.

8. Discuss the importance of following safety protocols when working with wood coatings.

- Wood coatings can contain harmful chemicals, so it’s crucial to wear protective gear (e.g., gloves, mask, goggles).

- Proper ventilation is essential to prevent exposure to fumes and airborne particles.

- Coating materials should be stored and handled according to manufacturer’s instructions to avoid spills and accidents.

- Waste materials should be disposed of properly to minimize environmental impact.

9. Describe the challenges you have faced in previous wood coating projects and how you overcame them.

- Uneven surface: Used a sanding block to level the surface before applying the coating.

- Bubbles: Degassed the coating and applied thin layers to eliminate trapped air.

- Mismatched colors: Tested different shades on scrap wood to ensure a perfect match before applying to the main surface.

- Drying defects: Adjusted the temperature and humidity in the drying oven to achieve optimal curing conditions.

10. Explain how you stay up-to-date with the latest advancements in wood coating technologies and techniques.

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Collaborate with manufacturers and suppliers for technical updates.

- Experiment with new products and techniques in controlled environments before applying them to actual projects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Coater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Coater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wood Coater is a skilled professional responsible for applying protective coatings, stains, and finishes to wood surfaces. Their primary tasks include preparing wood surfaces, selecting and applying appropriate coatings, and ensuring the quality of the final product. Key job responsibilities include:

1. Surface Preparation

Preparing wood surfaces by cleaning, sanding, and filling imperfections to ensure proper adhesion of coatings.

- Identifying and removing dirt, dust, and debris from wood surfaces

- Sanding surfaces to smooth rough areas and create a uniform texture

- Filling cracks, gaps, and other imperfections with wood filler or epoxy

2. Coating Selection and Application

Selecting and applying appropriate coatings based on the desired finish and environmental conditions.

- Understanding different types of wood coatings, such as stains, sealers, varnishes, and paints

- Choosing the right coating for the specific wood type, intended use, and desired result

- Applying coatings evenly and efficiently using brushes, rollers, or spray equipment

3. Quality Control

Inspecting and testing coated surfaces to ensure they meet quality standards.

- Using measuring tools and gauges to verify coating thickness and coverage

- Conducting adhesion tests to ensure coatings are properly bonded to the wood surface

- Identifying and correcting any defects or imperfections in the coating

4. Maintenance and Troubleshooting

Maintaining coating equipment, tools, and workspace.

- Cleaning and servicing brushes, rollers, and spray equipment

- Organizing and maintaining a clean and efficient workspace

- Troubleshooting and resolving common coating problems, such as uneven application or discoloration

Interview Tips

To prepare for an interview for a Wood Coater position, it is crucial to showcase your technical skills, attention to detail, and passion for woodworking.

1. Research the Company and Position

Thoroughly research the company and the specific Wood Coater position you are applying for. This will help you understand their business, values, and the requirements of the role.

- Visit the company website to learn about their products, services, and industry standing

- Review the job description carefully to identify the essential qualifications and responsibilities

2. Highlight Your Technical Skills

Emphasize your technical abilities in surface preparation, coating selection, and application. Provide specific examples of your experience and expertise.

- Describe the types of wood surfaces you have worked with and the techniques you used to prepare them

- Discuss your knowledge of different wood coatings, their properties, and their suitability for various applications

- Share your experience with different coating application methods and the quality control procedures you have followed

3. Showcase Your Attention to Detail

Wood coating requires precision and attention to detail. Emphasize your ability to work meticulously and ensure the highest quality standards.

- Provide examples of projects where you have achieved exceptional results in terms of surface smoothness, even coating application, and durability

- Explain your approach to identifying and correcting defects or imperfections in coated surfaces

- Highlight your experience with using measuring tools and gauges to ensure coating thickness and coverage meet specifications

4. Express Your Passion for Woodworking

Wood coating is a craft that requires passion and dedication. Express your enthusiasm for woodworking and explain how it motivates you to deliver exceptional results.

- Share your previous experience in woodworking or related fields, such as carpentry or furniture making

- Explain how your interest in the aesthetics and functionality of wood drives you to achieve excellence in coating

- Discuss your aspirations for professional growth and how you see this role as a step towards achieving your goals in the woodworking industry

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wood Coater role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.