Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wood Dowel Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wood Dowel Machine Operator so you can tailor your answers to impress potential employers.

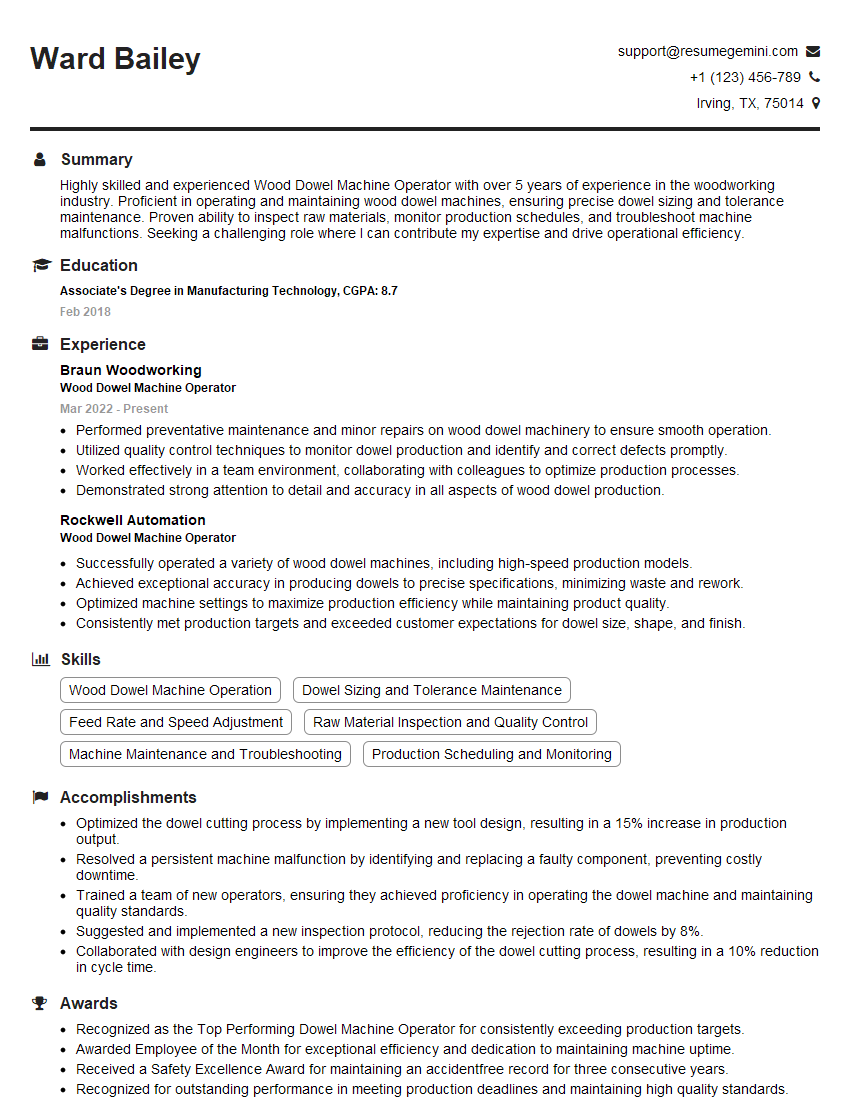

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Dowel Machine Operator

1. Explain the process of setting up a wood dowel machine?

- Inspect the machine for any safety hazards or damage.

- Mount the appropriate dowel forming head and adjust it to the desired dowel diameter.

- Load the raw wood stock into the machine’s feed hopper.

- Set the machine’s speed and feed rate according to the type of wood and the desired dowel size.

- Calibrate the machine’s sensors to ensure accurate dowel length and diameter.

2. How do you ensure the quality of the dowels produced by the machine?

Inspecting Raw Materials

- Check the wood stock for knots, cracks, or other defects that could affect dowel quality.

- Ensure that the wood is properly seasoned to prevent warping or splitting.

Monitoring Machine Performance

- Regularly check the machine’s settings to ensure they are within specifications.

- Monitor the dowel diameter and length to detect any deviations from the desired dimensions.

- Listen for unusual noises or vibrations that may indicate machine malfunctions.

Conducting Quality Control

- Randomly sample dowels from the production line and measure their dimensions.

- Inspect the dowels for surface defects, such as scratches or splinters.

- Perform destructive testing to assess the dowel’s strength and durability.

3. Describe the safety precautions that you follow when operating a wood dowel machine?

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Keep the work area clean and free of debris to prevent slips and falls.

- Never operate the machine without the appropriate guards and shields in place.

- Be aware of the moving parts of the machine and keep hands and clothing clear.

- Follow all manufacturer’s instructions and safety guidelines for the specific machine model.

4. What types of maintenance tasks are required for a wood dowel machine?

- Regularly clean and lubricate the machine’s moving parts, such as bearings, gears, and chains.

- Inspect the machine’s electrical components for any damage or loose connections.

- Check the machine’s cutting head for wear or damage and replace it if necessary.

- Calibrate the machine’s sensors and gauges to ensure accurate measurements.

- Perform scheduled maintenance as recommended by the machine manufacturer.

5. How do you handle production issues, such as machine downtime or quality defects?

- Identify the root cause of the issue by troubleshooting the machine and the production process.

- Take immediate action to resolve the issue, such as repairing the machine or adjusting the settings.

- Communicate with the supervisor and other relevant personnel to coordinate a solution.

- Document the issue and the steps taken to resolve it for future reference.

6. What experience do you have in optimizing wood dowel machine performance?

- Worked with engineers to analyze machine data and identify areas for improvement.

- Implemented process modifications, such as adjusting feed rates and cutter speeds, to increase efficiency.

- Conducted experiments to evaluate the effects of different cutting tools and materials on dowel quality.

- Developed and implemented maintenance schedules to minimize downtime and improve machine reliability.

7. How do you keep up with advancements in wood dowel machine technology?

- Attend industry conferences and trade shows to learn about new technologies and best practices.

- Read technical journals and online resources to stay informed about the latest developments.

- Network with other Wood Dowel Machine Operators and industry professionals to share knowledge and insights.

- Seek opportunities for training and certification to enhance my skills and stay up-to-date with the latest technology.

8. What is your understanding of the different types of wood dowels and their applications?

- Hardwood dowels (e.g., oak, maple, birch): Stronger and more durable, used in furniture, flooring, and structural applications.

- Softwood dowels (e.g., pine, fir, spruce): Less expensive and easier to work with, used in crafts, DIY projects, and non-structural applications.

- Treated dowels: Treated with chemicals to resist moisture, insects, and decay, suitable for outdoor use.

- Fluted dowels: Feature spiral grooves that improve glue adhesion, used in furniture making and dowel joints.

9. How do you ensure that the dowels produced meet the customer’s specifications?

- Review the customer’s specifications carefully.

- Inspect the dowels for length, diameter, and surface quality.

- Measure the dowels using precision instruments to ensure they meet the desired dimensions.

- Perform destructive or non-destructive testing to verify the dowel’s strength and durability.

- Maintain accurate records of the inspection and testing results.

10. Describe a time when you had to troubleshoot a problem with a wood dowel machine.

- Identified the problem as worn cutting heads.

- Replaced the cutting heads with new ones.

- Adjusted the machine settings to compensate for the new cutting heads.

- Verified the dowel quality and dimensions.

- Documented the troubleshooting process and the solution for future reference.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Dowel Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Dowel Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wood Dowel Machine Operator is responsible for operating and maintaining wood dowel machines, used to create cylindrical dowels from wood. Their primary duties include:

1. Machine Operation

Setting up and operating wood dowel machines, ensuring proper feed rates, speeds, and settings.

- Monitoring machine performance, making necessary adjustments to optimize production.

- Inspecting finished dowels for defects and ensuring they meet specifications.

2. Maintenance and Troubleshooting

Performing routine maintenance on wood dowel machines, including cleaning, lubrication, and minor repairs.

- Identifying and resolving machine malfunctions, diagnosing problems and implementing appropriate solutions.

3. Quality Control

Maintaining the quality of dowel products by adhering to established standards and specifications.

- Conducting inspections throughout the production process to ensure quality.

- Taking corrective actions to address any deviations from quality standards.

4. Production Optimization

Maximizing machine efficiency and productivity by implementing best practices and identifying areas for improvement.

- Working closely with production team to optimize workflow and minimize downtime.

- Suggesting and implementing process improvements to increase efficiency.

Interview Tips

To ace an interview for a Wood Dowel Machine Operator position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry standing. Understand the specific responsibilities and requirements of the Wood Dowel Machine Operator role.

- Practice answering common interview questions related to your skills, experience, and qualifications.

- Prepare thoughtful questions to ask the interviewer, demonstrating your interest and engagement.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating and maintaining wood dowel machines. Quantify your experience and accomplishments, using specific examples to demonstrate your abilities.

- Discuss your knowledge of wood doweling techniques, including feed rates, speeds, and quality control measures.

- Share instances where you identified and resolved machine malfunctions, showcasing your troubleshooting skills.

3. Showcase Quality Consciousness

Convey your strong commitment to maintaining high-quality standards. Describe your attention to detail and ability to consistently produce exceptional dowel products.

- Mention your understanding of industry standards and regulations related to wood dowel production.

- Provide examples of how you have implemented quality control measures to ensure product excellence.

4. Demonstrate Continuous Improvement Mindset

Express your eagerness to learn, grow, and improve your skills as a Wood Dowel Machine Operator.

- Discuss your interest in staying up-to-date with the latest industry advancements and best practices.

- Share your ideas for optimizing machine performance and increasing productivity.

Next Step:

Now that you’re armed with the knowledge of Wood Dowel Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wood Dowel Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini