Are you gearing up for an interview for a Wood Drilling Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wood Drilling Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

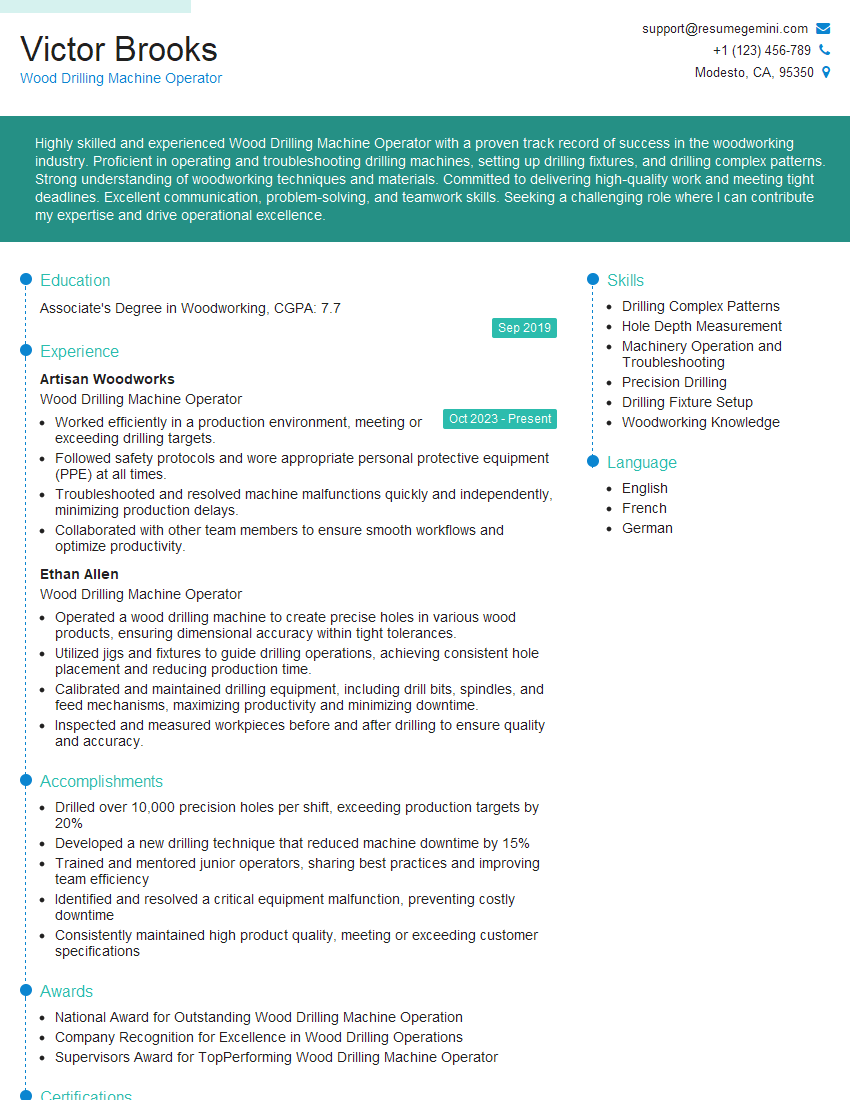

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Drilling Machine Operator

1. What are the different types of wood drilling machines?

There are various types of wood drilling machines, including:

- Benchtop drill presses: Compact and suitable for small-scale drilling operations

- Floor drill presses: Larger and more powerful, designed for heavy-duty drilling

- Radial arm drill presses: Allow for precise drilling at various angles and locations

- Multi-spindle drill presses: Equipped with multiple spindles for simultaneous drilling of multiple holes

- CNC drill presses: Computer-controlled machines for high-precision and repetitive drilling tasks

2. What factors should be considered when selecting drill bits for wood?

Material

- Different woods require specific drill bit materials, such as high-speed steel (HSS) for softwoods and carbide-tipped bits for hardwoods

Bit size

- Drill bit size should match the desired hole diameter and the thickness of the wood being drilled

Bit shape

- Twist drill bits are the most common, but specialty bits, such as brad point bits, are available for specific applications

Bit sharpness

- Sharp drill bits prevent tearing and ensure clean, precise holes

3. What are the common problems encountered when drilling wood?

Some common problems include:

- Tearing: Caused by dull drill bits or incorrect cutting speeds

- Splitting: Occurs when the drill bit exits the wood, especially when drilling near edges

- Burn Marks: Result from excessive friction or incorrect drilling speed

- Wobbly Holes: Caused by unstable machine setups or improper drill bit clamping

- Binding: Occurs when the drill bit becomes stuck in the wood, potentially causing damage

4. Describe the steps involved in setting up a wood drilling machine.

Typically, setting up a wood drilling machine involves the following steps:

- Mount the machine: Securely fasten the machine to a stable surface

- Install the drill bit: Select the appropriate drill bit and insert it into the chuck

- Set the speed and depth: Adjust the machine settings to match the wood type and desired hole size

- Align the workpiece: Position the workpiece securely on the table or fixture

- Engage the drill: Engage the drill and slowly feed the workpiece into the drill bit

5. How do you ensure safety when operating a wood drilling machine?

Safety measures include:

- Wear proper safety gear: Eye protection, gloves, and appropriate clothing

- Secure the workpiece: Prevent it from moving unexpectedly during drilling

- Maintain a clean work area: Remove debris and keep the machine clean

- Avoid loose clothing: Prevent it from getting caught in moving parts

- Inspect equipment regularly: Check for damaged wires, bits, or other components before each use

6. What maintenance tasks are required for a wood drilling machine?

Regular maintenance includes:

- Cleaning: Remove dirt, sawdust, and debris from the machine

- Oiling: Lubricate moving parts to reduce friction

- Drill bit sharpening: Ensure sharpness for optimal performance

- Chuck inspection: Check the chuck for wear or damage

- Belt replacement: Replace belts as needed to maintain proper tension

7. Describe the difference between a pilot hole and a countersink.

A pilot hole is a small hole drilled before the main hole to guide the drill bit and prevent splitting. Conversely, a countersink is a tapered hole drilled into the surface of the material to allow a screw or bolt head to sit flush or below the surface.

8. What techniques can be used to drill a straight hole in wood?

Techniques to ensure straight holes include:

- Using a drill guide: A jig that aligns the drill bit perpendicular to the workpiece

- Starting with a pilot hole: Creates a small hole to stabilize the drill bit and minimize wandering

- Clamping the workpiece securely: Prevents movement during drilling

- Applying even pressure: Maintaining consistent force while feeding the drill bit

9. How do you prevent drill bits from overheating?

To prevent overheating:

- Use sharp drill bits: Dull bits generate more heat

- Set the correct drilling speed: Too high speeds increase friction

- Apply cutting fluid: Lubricate the drill bit and reduce heat

- Allow the drill bit to cool: Periodically stop drilling to let it cool down

10. What are the different types of drilling operations performed on wood?

Common drilling operations include:

- Through-hole drilling: Creating a hole that extends through the entire thickness of the material

- Blind-hole drilling: Creating a hole that does not go all the way through

- Countersinking: Creating a tapered hole for a screw or bolt head

- Dowel drilling: Drilling holes for dowel joints

- Plug cutting: Drilling holes and cutting plugs to conceal screw or nail holes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Drilling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Drilling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wood Drilling Machine Operator is responsible for operating and maintaining a wood drilling machine to create precise holes in wood materials. Their key job responsibilities include:

1. Machine Operation

Operate wood drilling machines to create holes in wood components as per specifications

- Set up and adjust drilling machines for various hole sizes and depths

- Load and secure wood pieces into the machine

- Drill holes accurately and efficiently, ensuring the required precision

2. Machine Maintenance

Perform routine maintenance and repairs on wood drilling machines

- Inspect machines regularly for any wear or damage

- Clean and lubricate machines as per recommended guidelines

- Identify and resolve minor technical issues, or report major problems to supervisors

3. Material Handling

Handle wood materials and components safely and efficiently

- Load and unload wood pieces from the machine

- Move heavy or bulky wood materials using appropriate equipment

- Maintain a clean and organized work area

4. Quality Control

Ensure the quality and accuracy of drilled holes

- Inspect drilled holes for precision, size, and depth

- Adhere to established quality standards and specifications

- Maintain accurate records of machine settings and hole dimensions

Interview Tips

To ace an interview for a Wood Drilling Machine Operator position, it’s essential to prepare effectively and demonstrate your skills and knowledge. Here are some interview tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific role you’re applying for. This will give you a good understanding of their business, industry, and the requirements of the job.

- Visit the company website to learn about their products, services, and values.

- Read job descriptions carefully to identify the key responsibilities and qualifications.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience. Practice delivering your answers clearly and confidently.

- Prepare answers to questions about your drilling machine operation experience, maintenance knowledge, and quality control procedures.

- Practice describing your ability to work in a team environment and meet deadlines.

3. Highlight Your Safety Awareness

In this role, safety is paramount. Emphasize your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Explain how you follow established safety procedures and use personal protective equipment.

- Discuss your experience in identifying and mitigating potential hazards.

4. Show Your Attention to Detail

As a Wood Drilling Machine Operator, precision and accuracy are crucial. Showcase your attention to detail by providing examples of your ability to follow instructions carefully and achieve desired results.

- Describe your experience in measuring and marking wood pieces accurately.

- Explain how you ensure that drilled holes meet the required specifications.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the position and the company. This shows that you’re engaged and eager to learn more.

- Ask about the company’s growth plans and industry trends.

- Inquire about opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Drilling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!