Feeling lost in a sea of interview questions? Landed that dream interview for Wood Getter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wood Getter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

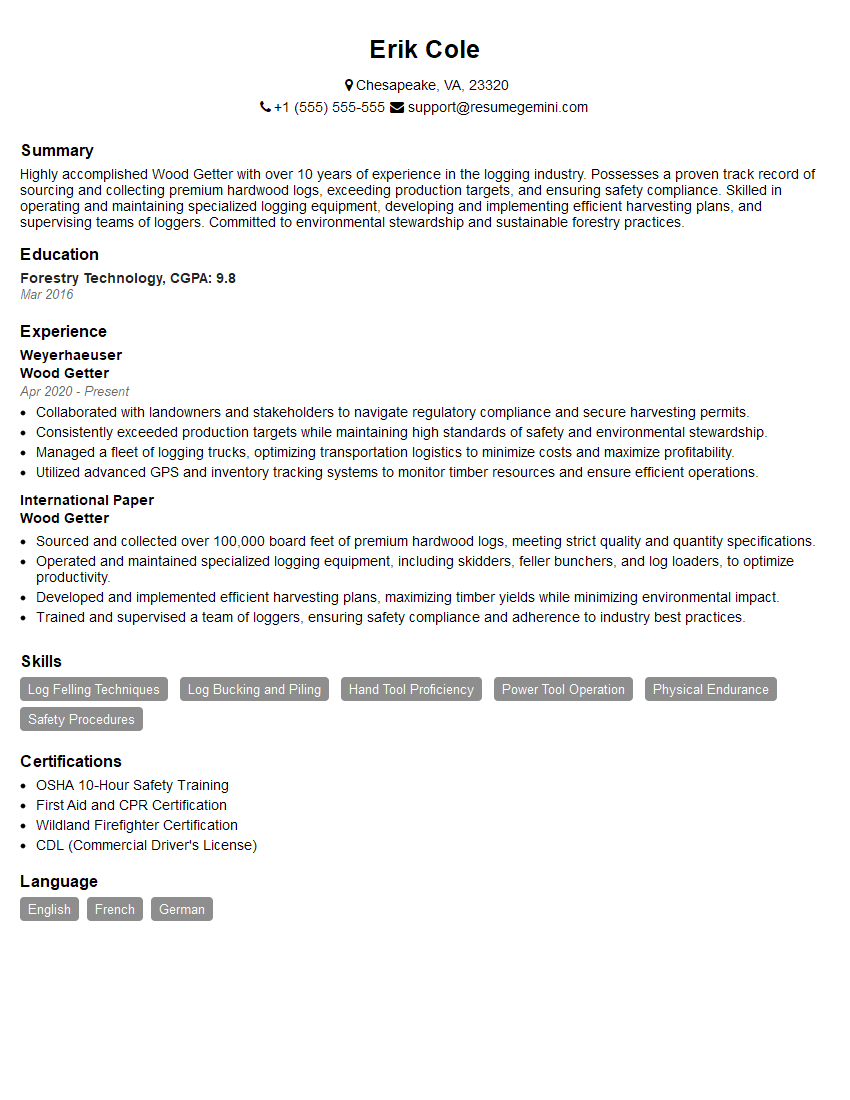

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Getter

1. How do you ensure that the wood you get is of high quality?

When selecting wood, we follow a rigorous quality control process to guarantee its optimal condition:

- Visual Inspection: We carefully examine each piece for any visible defects, such as knots, cracks, or discoloration, to ensure it meets our quality standards.

- Moisture Content Testing: Using moisture meters, we measure the wood’s moisture content to ensure it is within the acceptable range. This prevents warping, splitting, or other problems during use.

- Strength and Durability Tests: We perform various tests, including bending and compression tests, to assess the wood’s strength and durability. This helps us determine its suitability for different applications.

- Species Identification: We use our expertise in wood identification to verify the species of each piece and ensure it aligns with the desired characteristics and performance.

2. What are the different types of wood that you are familiar with and their properties?

Hardwoods

- Oak: Known for its strength, durability, and resistance to rot.

- Mahogany: Highly prized for its rich color, fine grain, and resistance to decay.

- Maple: Characterized by its hardness, light color, and resistance to wear.

Softwoods

- Pine: Widely used for construction due to its availability, affordability, and ease of workability.

- Fir: Known for its straight grain, light weight, and good strength-to-weight ratio.

- Cedar: Highly resistant to decay and insects, making it ideal for outdoor applications.

3. How do you manage the inventory of wood and ensure that you have the right amount of different types of wood in stock?

We employ a comprehensive inventory management system to effectively manage our wood stock and maintain optimal levels of each type of wood:

- Real-Time Inventory Tracking: We utilize software to track inventory levels in real time, providing accurate information on available stock.

- Demand Forecasting: We analyze historical data and market trends to forecast demand for different types of wood, ensuring we have sufficient quantities.

- Supplier Relationships: We maintain strong relationships with our suppliers to secure a reliable supply of various wood species and grades.

- Regular Stock Audits: We conduct regular physical audits of our inventory to verify accuracy and identify any discrepancies.

4. What are the common challenges you face in your role as a Wood Getter, and how do you overcome them?

As a Wood Getter, we encounter various challenges, but we proactively address them to ensure efficient operations:

- Fluctuating Market Prices: We monitor market trends and adjust our procurement strategies to mitigate the impact of price fluctuations.

- Supply Chain Disruptions: We have established alternative supply chains and maintain close relationships with multiple suppliers to minimize the risk of disruptions.

- Quality Control: We implement rigorous quality assurance measures at every stage, from sourcing to delivery, to ensure the quality of our wood.

- Environmental Regulations: We stay updated on environmental regulations and adhere to sustainable practices throughout our operations.

5. How do you stay informed about the latest industry trends and advancements in wood processing techniques?

To stay up-to-date with industry trends and advancements, we engage in continuous learning and knowledge acquisition:

- Industry Publications: We subscribe to industry magazines, journals, and newsletters to stay informed about the latest news and insights.

- Conferences and Trade Shows: We attend industry events to network with experts, learn about new technologies, and explore innovative solutions.

- Online Resources: We utilize online databases, websites, and forums to access a wealth of information and connect with industry professionals.

- Collaboration with Suppliers: We partner with suppliers who are at the forefront of wood processing advancements to gain knowledge and access to their expertise.

6. What is your understanding of sustainable forestry practices, and how do you incorporate them into your work?

Sustainable forestry practices are crucial in our operations, and we actively incorporate them to ensure the long-term health of forests:

- Responsible Harvesting: We follow sustainable harvesting techniques to minimize environmental impact and promote forest regeneration.

- Reforestation Initiatives: We participate in reforestation programs to replenish forests and contribute to biodiversity conservation.

- Supplier Certification: We work with suppliers who adhere to recognized forestry certifications, such as FSC or SFI, to ensure responsible sourcing.

- Compliance with Regulations: We comply with all applicable environmental regulations and guidelines to protect forests and ecosystems.

7. How do you ensure that the wood you supply meets the specific requirements and specifications of your customers?

To meet our customers’ unique needs, we follow a comprehensive process:

- Detailed Specifications: We establish clear and detailed specifications for each order, including dimensions, grade, and quality requirements.

- Custom Sourcing: We are able to source specific types of wood based on the customer’s requirements, even if it involves locating rare or exotic species.

- Quality Control: We conduct thorough quality inspections before shipment to ensure that the wood meets the agreed-upon specifications and standards.

- Customer Communication: We maintain open communication with customers throughout the process, providing updates and addressing any concerns.

8. Describe your experience in managing large-scale wood procurement projects.

I have extensive experience in managing large-scale wood procurement projects, ensuring the timely delivery of high-quality wood:

- Project Planning: I meticulously plan and coordinate each project, establishing timelines, budgets, and resource allocation strategies.

- Supplier Negotiations: I negotiate contracts with suppliers to secure the most favorable terms, including pricing, delivery schedules, and quality guarantees.

- Logistics Management: I oversee the transportation and logistics of wood shipments, ensuring efficient delivery to the project site.

- Quality Control: I implement comprehensive quality control measures throughout the project, monitoring the wood’s condition and adherence to specifications.

9. How do you measure and evaluate the performance of your wood procurement operations?

I employ various metrics and strategies to evaluate the performance of my wood procurement operations:

- Cost Analysis: I track and analyze procurement costs to optimize spending and identify areas for improvement.

- Quality Control Metrics: I monitor quality control data to assess the effectiveness of our quality assurance processes and identify any quality issues.

- Delivery Performance: I track delivery times and customer satisfaction to evaluate the efficiency and reliability of our supply chain.

- Customer Feedback: I gather and analyze customer feedback to identify areas for improvement and ensure customer satisfaction.

10. How do you stay motivated and driven in your role as a Wood Getter?

I find immense motivation and drive in my role as a Wood Getter due to several factors:

- Contribution to Sustainability: I am passionate about contributing to sustainable forestry practices and providing eco-friendly materials.

- Variety and Challenges: The constant variety and challenges of my role keep me engaged and motivated to find innovative solutions.

- Customer Satisfaction: Meeting and exceeding customer expectations gives me a sense of accomplishment and drives me to deliver the best possible results.

- Personal Growth: The opportunity for professional development and continuous learning in the wood industry fuels my motivation to excel.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Getter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Getter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Getters are responsible for cutting, splitting, and stacking firewood, among other tasks. They must be able to work independently and as part of a team, and they must be able to lift heavy objects. Wood Getters typically work outdoors in all types of weather, and they must be able to work in a variety of terrain.

1. Cut down trees

Wood Getters use axes, chainsaws, and other tools to cut down trees. They must be able to safely and efficiently fell trees, and they must be able to work in a variety of terrain.

- Use axes, chainsaws, and other tools to cut down trees.

- Safely and efficiently fell trees.

- Work in a variety of terrain.

2. Split and stack firewood

Wood Getters use axes, mauls, and other tools to split and stack firewood. They must be able to split firewood into uniform pieces, and they must be able to stack firewood in a way that prevents it from falling over.

- Use axes, mauls, and other tools to split firewood.

- Split firewood into uniform pieces.

- Stack firewood in a way that prevents it from falling over.

3. Load and unload firewood

Wood Getters load and unload firewood from trucks and other vehicles. They must be able to lift heavy objects, and they must be able to work in a variety of terrain.

- Load and unload firewood from trucks and other vehicles.

- Lift heavy objects.

- Work in a variety of terrain.

4. Maintain equipment

Wood Getters maintain their own equipment, including axes, chainsaws, and other tools. They must be able to sharpen axes and chainsaws, and they must be able to repair minor equipment problems.

- Maintain their own equipment, including axes, chainsaws, and other tools.

- Sharpen axes and chainsaws.

- Repair minor equipment problems.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go to an interview, it is important to do your research. Learn as much as you can about the company, the position you are applying for, and the industry. This will help you answer questions intelligently and show that you are genuinely interested in the opportunity.

- Visit the company’s website.

- Read articles about the company and the industry.

- Talk to people who work for the company.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- How do you handle stress?

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you are applying for.

- Wear a suit or dress pants and a button-down shirt.

- Avoid wearing jeans, t-shirts, or athletic shoes.

- Make sure your clothes are clean and pressed.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, call or email the interviewer to let them know.

- Give yourself plenty of time to get to the interview location.

- If you are running late, call or email the interviewer.

- Do not be more than 15 minutes late for your interview.

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and direct in your answers.

- Don’t try to be someone you’re not.

- Let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Getter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.