Are you gearing up for an interview for a Wood Handler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wood Handler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

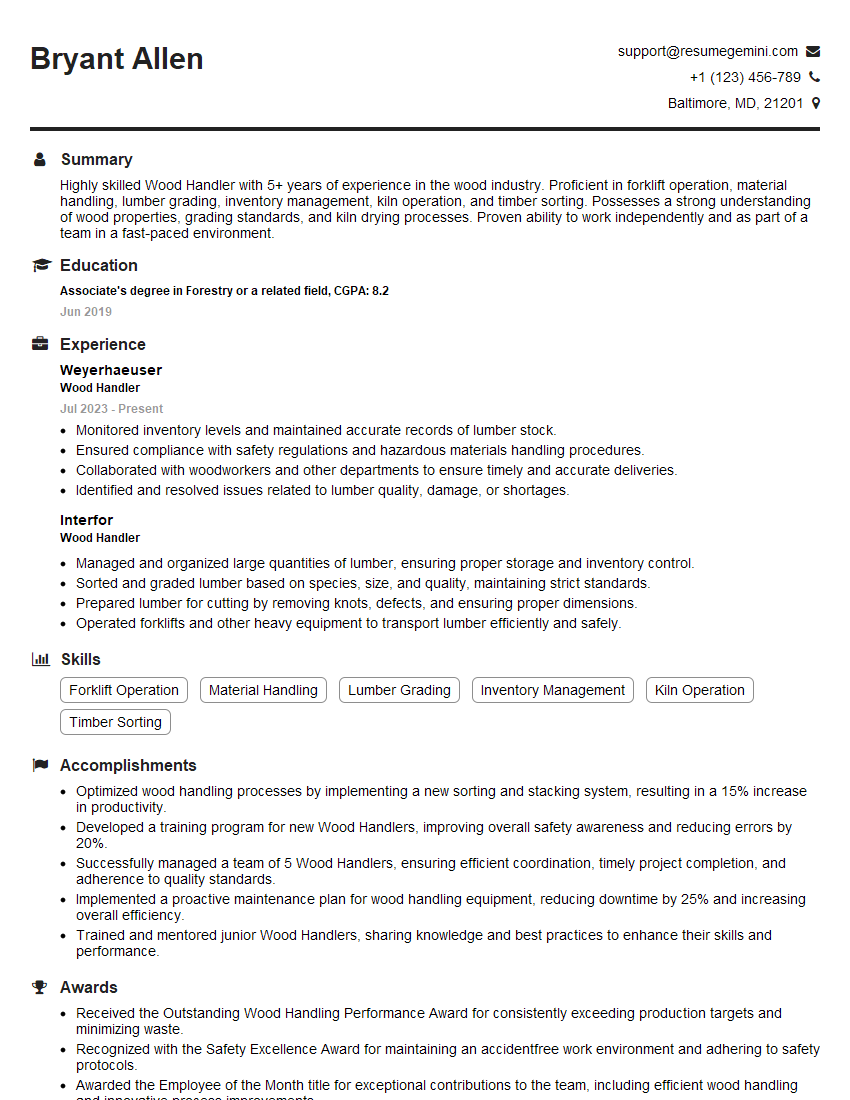

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Handler

1. What are the different types of wood used in woodworking?

There are various types of wood used in woodworking, each with its unique properties and applications. Some of the most common types include:

- Hardwoods: Hardwoods are derived from deciduous trees, and they are generally denser, more durable, and more expensive than softwoods. Examples include oak, maple, cherry, and mahogany.

- Softwoods: Softwoods come from coniferous trees, and they are typically lighter, less durable, and less expensive than hardwoods. Common softwoods include pine, fir, spruce, and cedar.

- Engineered Wood: Engineered wood is manufactured by combining wood pieces with adhesives or other materials to create a composite material. Types of engineered wood include plywood, particleboard, and medium-density fiberboard (MDF).

2. How do you prepare wood for woodworking?

Before Cutting

- Safety First: Wear appropriate safety gear, including eye protection, gloves, and a dust mask.

- Select Suitable Wood: Choose wood that is appropriate for the project in terms of species, grain pattern, and moisture content.

- Moisture Content: Check the moisture content of the wood using a moisture meter. Ideal moisture content for woodworking is between 6% and 8%.

Cutting

- Sharpen Tools: Ensure that your saws, chisels, and other cutting tools are sharp for clean and precise cuts.

- Use Proper Techniques: Follow proper cutting techniques, such as using a miter saw for cross-cuts and a table saw for rip-cuts.

- Measure Accurately: Use measuring tapes, rulers, and squares to ensure precise measurements and cuts.

3. What are the different types of woodworking joints?

There are numerous types of woodworking joints, each serving a specific purpose. Here are some common types:

- Butt Joint: A simple joint where two pieces of wood are placed side by side and glued or nailed.

- Miter Joint: Two pieces of wood are cut at a 45-degree angle and joined to form a corner.

- Lap Joint: One piece of wood overlaps another, creating a stronger joint than a butt joint.

- Dado Joint: A groove is cut into one piece of wood, and the other piece fits into the groove, providing a strong and concealed joint.

- Mortise and Tenon Joint: A mortise (hole) is cut into one piece of wood, and a tenon (projection) is cut on the other piece, which fits into the mortise, creating a very strong joint.

4. What are the different types of woodworking machines and their uses?

Woodworking machines are essential tools for efficient and precise woodworking. Some common types include:

- Table Saw: Used for ripping, cross-cutting, and angled cuts.

- Miter Saw: Specifically designed for making precise miter cuts.

- Jointer: Flattens and straightens the edges of boards.

- Planer: Removes material from the surface of the wood to achieve a smooth and even finish.

- Drill Press: Used for drilling precise holes.

5. What are the safety precautions to consider when working with wood?

- Wear Protective Gear: Always wear eye protection, gloves, and a dust mask to protect against flying wood chips and dust.

- Use Sharp Tools: Dull tools can slip and cause accidents. Keep your tools sharp for safe and efficient cutting.

- Control the Workpiece: Securely clamp or hold the workpiece before cutting or shaping to prevent accidents.

- Be Aware of Your Surroundings: Keep the work area clean and free of clutter to avoid tripping or bumping into equipment.

- Follow Machine Instructions: Always read and follow the instructions for each machine you use to ensure safe operation.

6. How do you grain-match wood for a seamless appearance?

- Identify the Grain Pattern: Examine the wood pieces and determine the direction of the wood grain.

- Align the Grain: Place the wood pieces side by side and align the grain patterns to create a smooth transition.

- Use Clamps or Tape: Secure the wood pieces together using clamps or tape to hold them in place during gluing.

- Apply Glue Sparingly: Apply a thin layer of wood glue to the mating surfaces and press the pieces together firmly.

- Wipe Excess Glue: Use a damp cloth to wipe away any excess glue that squeezes out from the joint.

7. How do you repair common wood defects, such as knots or cracks?

Repairing wood defects requires different techniques depending on the type of defect:

- Knots: Small knots can be filled with wood filler or epoxy. For larger knots, a knot hole can be drilled, and a dowel or plug can be inserted and glued in place.

- Cracks: Fine cracks can be filled with wood filler or cyanoacrylate glue. For wider cracks, a spline or butterfly joint can be used to reinforce the joint and prevent further cracking.

- Splits: Splits can be repaired by gluing and clamping the split pieces back together. Reinforce the repair with screws or dowels for added strength.

8. How do you maintain and sharpen woodworking tools?

- Clean Tools Regularly: Remove sawdust, glue, and other debris from your tools after each use to prevent rust and buildup.

- Sharpen Cutting Tools: Use a whetstone, sharpening stone, or honing guide to sharpen your saws, chisels, and other cutting tools regularly.

- Lubricate Moving Parts: Apply a light lubricant, such as machine oil or WD-40, to moving parts of your tools to reduce friction and extend their lifespan.

- Store Tools Properly: Store your tools in a dry and organized manner to prevent damage and rust.

9. What are the different types of wood finishes and their applications?

- Oil Finishes: Penetrate the wood to protect and enhance the natural grain. Examples include linseed oil, tung oil, and Danish oil.

- Varnish: Creates a hard, protective coating on the wood. Available in gloss, semi-gloss, and matte finishes.

- Polyurethane: Similar to varnish, but more durable and resistant to wear and tear.

- Lacquer: A quick-drying finish that provides a high-gloss shine. Often used on musical instruments and furniture.

- Wax: Provides a protective and water-resistant coating. Easy to apply and maintain.

10. How do you handle and transport large or heavy pieces of wood?

- Use Proper Equipment: Utilize dollies, hand trucks, or forklifts to move heavy pieces of wood safely.

- Team Up: For exceptionally large or heavy pieces, work with a partner or team to lift and carry.

- Protect the Wood: Use blankets, straps, or padding to protect the wood from damage during transportation.

- Secure the Load: Ensure that the wood is securely fastened to the transportation vehicle to prevent shifting and damage.

- Be Aware of Your Surroundings: Plan the route and be aware of potential obstacles or hazards during transportation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Handler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Handler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood handlers, also known as lumber handlers, play a crucial role in the movement, storage, and handling of wood and lumber products within various industries, including construction, manufacturing, and forestry.

1. Loading and Unloading Materials

Wood handlers are primarily responsible for loading and unloading wood and lumber products from trucks, trailers, railcars, and other modes of transportation.

- Operate forklifts, cranes, and other heavy equipment to load and unload materials.

- Ensure proper loading and unloading techniques to prevent damage to materials and equipment.

2. Storing and Inventory Management

They maintain a clean and organized storage area for wood and lumber products, ensuring proper inventory management.

- Stack and store lumber correctly according to size, species, and moisture content.

- Maintain accurate inventory records and monitor stock levels.

3. Quality Control

Wood handlers inspect wood and lumber products for any defects or damage before loading, unloading, or storing.

- Identify and reject damaged or defective materials.

- Ensure that lumber meets specified quality standards.

4. Safety and Equipment Maintenance

They adhere to safety regulations and maintain a safe work environment by following proper procedures for handling heavy equipment.

- Operate equipment safely and efficiently.

- Inspect and maintain equipment regularly to ensure proper functioning.

Interview Tips

Preparing thoroughly for a Wood Handler interview is essential to showcase your skills and experience and increase your chances of success.

1. Research the Company and Industry

Learn about the company’s operations, industry trends, and specific requirements for the Wood Handler role.

- Research the company’s website, LinkedIn page, and industry publications.

- Identify the key responsibilities and qualifications for the position.

2. Highlight Relevant Experience and Skills

Emphasize your experience in material handling, inventory management, and quality control.

- Quantify your accomplishments using specific metrics, such as the number of loads handled or inventory accuracy rates achieved.

- Demonstrate your proficiency in operating forklifts, cranes, and other heavy equipment.

3. Prepare for Safety and Equipment Knowledge Questions

Interviewers will likely assess your understanding of safety regulations and equipment maintenance.

- Review industry safety standards and best practices.

- Familiarize yourself with common equipment maintenance procedures.

4. Practice Your Answers to Behavioral Questions

Be prepared to answer questions about your teamwork skills, problem-solving abilities, and attention to detail.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide specific examples that demonstrate your relevant skills and experience.

5. Ask Thoughtful Questions

Ask insightful questions at the end of the interview to show your interest and engagement.

- Inquire about the company’s safety culture and training opportunities.

- Ask about the expectations and growth potential for the Wood Handler role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wood Handler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.