Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wood Heel Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

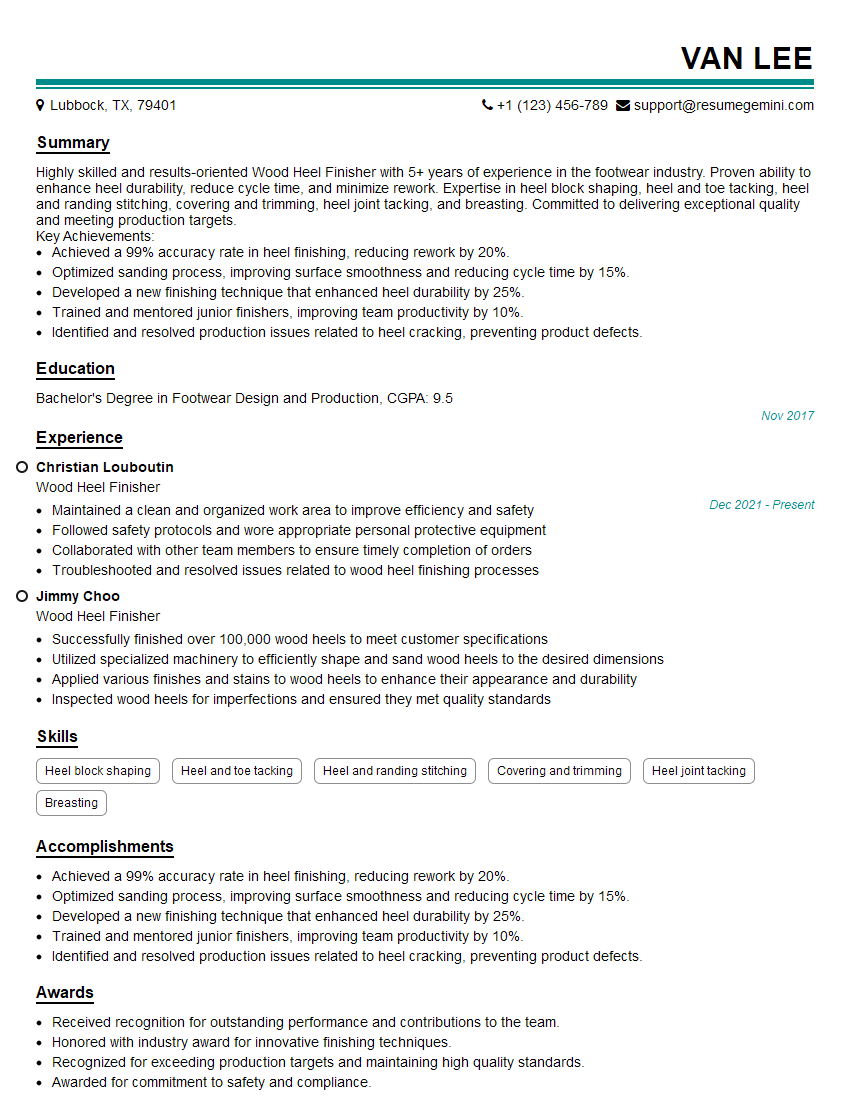

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Heel Finisher

1. Describe the process of heel attaching?

The process of heel attaching involves several steps:

- Preparing the heel and the shoe upper by sanding and applying adhesive.

- Positioning the heel on the upper and aligning it correctly using a nailing machine or a press.

- Attaching the heel securely by driving nails or applying pressure.

- Trimming any excess material and sanding the heel to achieve a smooth and finished appearance.

2. What are the different types of heels and their characteristics?

Stiletto heels

- Thin, high heels that are typically 2-4 inches in height.

- Provide a sophisticated and elegant look.

Block heels

- Square or rectangular heels with a wider base.

- Offer stability and comfort while still providing height.

3. What safety measures should be taken while operating a nailing machine?

When operating a nailing machine, it is crucial to adhere to the following safety measures:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Ensure that the machine is properly set up and calibrated.

- Keep the work area clear of obstructions and debris.

- Inspect the nails regularly to ensure they are not bent or damaged.

- Never place hands or fingers near the nailing point.

4. How do you ensure that the heels are attached straight and evenly?

To ensure that the heels are attached straight and evenly, I employ the following techniques:

- Using a marking tool or template to align the heels on the upper before attaching.

- Positioning the heel in the nailing machine or press carefully and adjusting as needed.

- Checking the alignment of the heel periodically during the attaching process.

- Utilizing a sanding block or other tools to smooth out any unevenness after attachment.

5. What are the common defects that can occur during heel attaching and how do you prevent them?

Common defects that can occur during heel attaching include:

- Misalignment: Prevent by using alignment tools and checking regularly.

- Uneven nailing: Prevent by ensuring proper machine calibration and careful nail placement.

- Splitting: Prevent by using the correct nail size and avoiding over-nailing.

6. How do you handle variations in heel height and shape?

To handle variations in heel height and shape, I:

- Adjust the height and pressure settings on the nailing machine or press accordingly.

- Use different nailing patterns or placements to accommodate different heel shapes.

- Manually sand or trim the heel after attachment to achieve the desired height and shape.

7. What is your approach to quality control in heel finishing?

My approach to quality control in heel finishing involves:

- Regularly inspecting heels for defects, such as misalignment, uneven nailing, or splitting.

- Using precision tools and techniques to ensure accuracy and consistency.

- Seeking feedback from colleagues or supervisors to improve quality.

8. How do you stay updated with industry best practices and technological advancements in heel finishing?

I stay updated with industry best practices and technological advancements in heel finishing through:

- Attending industry events, workshops, and conferences.

- Reading trade publications and online resources.

- Consulting with experts and manufacturers.

9. What is the importance of teamwork in the production environment?

Teamwork is crucial in the production environment for several reasons:

- Increased efficiency: Collaboration allows for sharing of knowledge, skills, and resources.

- Improved quality: Different perspectives and expertise contribute to better decision-making.

- Enhanced productivity: Teamwork can motivate individuals and foster a sense of accountability.

10. How do you handle pressure and prioritize tasks in a fast-paced production environment?

To handle pressure and prioritize tasks in a fast-paced production environment, I:

- Stay organized and manage my time effectively.

- Prioritize tasks based on urgency and importance.

- Delegate responsibilities to team members when necessary.

- Take breaks when needed to stay focused and productive.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Heel Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Heel Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Wood Heel Finisher is a crucial member of the production team, ensuring the quality and accuracy of wooden shoe heels. Their primary responsibilities include:

1. Heel Finishing

Using specialized machinery, sand and smooth wooden heels to achieve a polished and consistent finish.

2. Shaping and Profiling

Contour and shape heels according to specifications, using jigs, templates, and cutting tools.

3. Stain and Color Application

Apply stains or colors to enhance the appearance and durability of heels, following established color standards.

4. Assembly and Inspection

Attach heels to shoes securely, ensuring proper alignment and balance; inspect finished products for quality and adherence to specifications.

Interview Tips

To ace your Wood Heel Finisher interview, follow these tips:

1. Research the Company and Position

Thoroughly research the company and the specific role to demonstrate your interest and understanding of the industry.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience in wood finishing, machine operation, and quality control. Share specific examples of your craftsmanship and attention to detail.

3. Showcase Safety Knowledge and Compliance

Wood finishing processes can involve the use of hazardous materials and equipment. Stress your knowledge of safety protocols, proper handling techniques, and OSHA regulations.

4. Demonstrate Problem-Solving Abilities

Provide examples of how you solved production issues or implemented improvements in previous roles. This shows your ability to identify and resolve challenges.

5. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer about the company’s production processes, quality standards, and growth opportunities. This reflects your engagement and enthusiasm.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wood Heel Finisher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.