Are you gearing up for an interview for a Wood Mechanist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wood Mechanist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

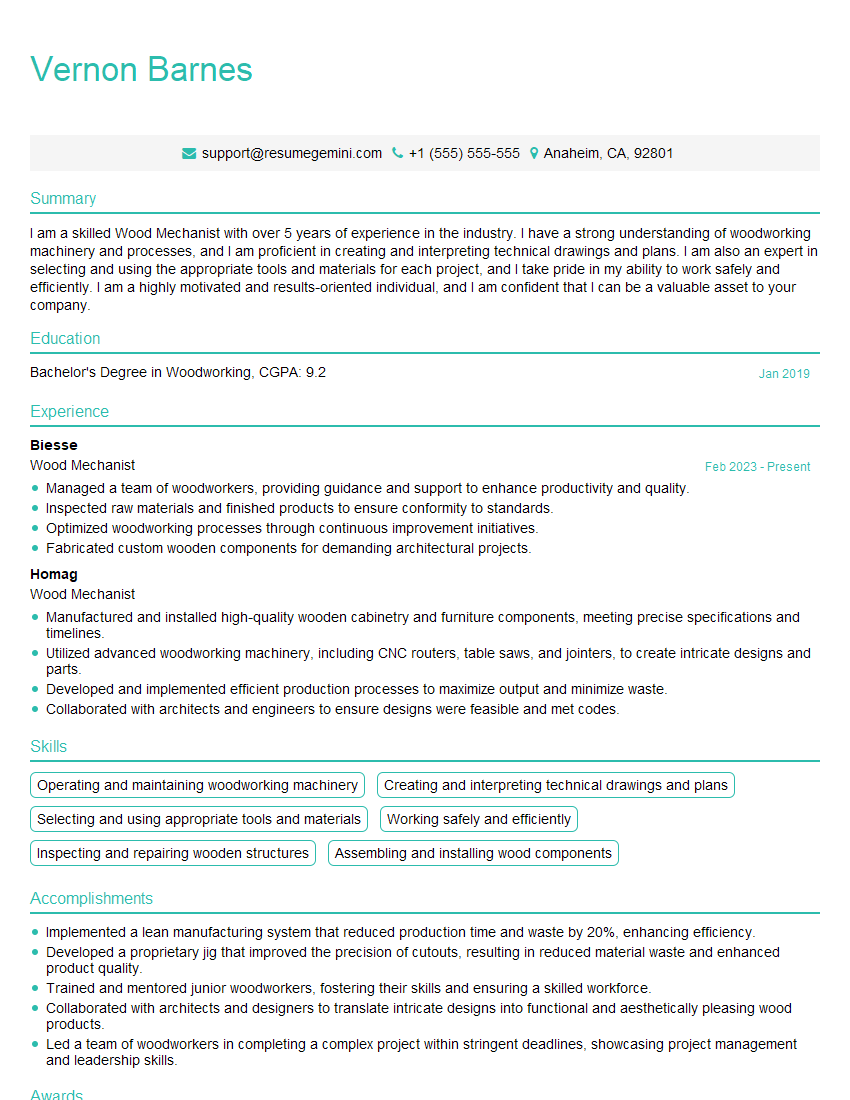

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Mechanist

1. What are the different types of wood joints used in woodworking?

There are many different types of wood joints used in woodworking, each with its own advantages and disadvantages. Some of the most common types of wood joints include:

- Butt joint

- Edge joint

- Mitre joint

- Mortise and tenon joint

- Dovetail joint

2. What is the difference between hardwood and softwood?

Properties of Hardwood

- Denser and stronger than softwood

- More durable and resistant to rot and decay

- More difficult to work with and requires specialized tools

Properties of Softwood

- Less dense and weaker than hardwood

- Less durable and more susceptible to rot and decay

- Easier to work with and requires less specialized tools

3. What are the different types of wood finishes?

There are many different types of wood finishes, each with its own unique properties and applications. Some of the most common types of wood finishes include:

- Oil finish

- Varnish finish

- Lacquer finish

- Shellac finish

- Polyurethane finish

4. What are the different types of woodworking machines?

There are many different types of woodworking machines, each designed for a specific task. Some of the most common types of woodworking machines include:

- Table saw

- Circular saw

- Miter saw

- Jointer

- Planer

- Drill press

- Sander

- Lathe

5. What are the safety precautions that should be taken when working with wood?

There are many safety precautions that should be taken when working with wood, including:

- Wear appropriate safety gear, including eye protection, hearing protection, and respiratory protection

- Use sharp tools and keep them in good condition

- Be aware of your surroundings and avoid tripping hazards

- Never operate woodworking machines without proper training

- Follow all manufacturer’s instructions for safe operation of woodworking machines

6. What are the different types of wood adhesives?

There are many different types of wood adhesives, each with its own unique properties and applications. Some of the most common types of wood adhesives include:

- PVA glue

- Epoxy glue

- Cyanoacrylate glue

- Hot melt glue

- Hide glue

7. What are the different types of wood stains?

There are many different types of wood stains, each with its own unique color and finish. Some of the most common types of wood stains include:

- Water-based stain

- Oil-based stain

- Gel stain

- Penetrating stain

- Wipe-on stain

8. What are the different types of wood preservatives?

There are many different types of wood preservatives, each with its own unique properties and applications. Some of the most common types of wood preservatives include:

- Water-repellent preservatives

- Oil-based preservatives

- Salt-based preservatives

- Borate-based preservatives

- Copper-based preservatives

9. What are the different types of woodworking tools?

There are many different types of woodworking tools, each designed for a specific task. Some of the most common types of woodworking tools include:

- Hand tools

- Power tools

- Measuring tools

- Marking tools

- Cutting tools

- Shaping tools

- Finishing tools

10. What is your experience with woodworking?

I have over 10 years of experience in woodworking, and I have worked on a wide variety of projects, including furniture making, cabinetry, and home improvement. I am proficient in the use of a variety of woodworking tools and machines, and I have a strong understanding of woodworking techniques and materials. I am also a certified woodworker.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Mechanist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Mechanist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Mechanists are responsible for operating and maintaining woodworking machinery to produce various wood products. Their key responsibilities include:

1. Machine Operation

Operating various woodworking machines, such as saws, drills, lathes, and routers, to cut, shape, and join wood components.

- Setting up and calibrating machines according to specifications.

- Ensuring machines are in good working order and conducting routine maintenance.

2. Material Handling

Handling and moving raw wood materials and finished products safely and efficiently.

- Inspecting and selecting suitable wood for the project.

- Loading and unloading materials from machines.

3. Production Planning

Working with supervisors and other team members to plan and schedule production activities.

- Estimating material requirements and production time.

- Monitoring production progress and identifying bottlenecks.

4. Quality Control

Inspecting finished products for defects and ensuring they meet quality standards.

- Using measuring tools and gauges to check dimensions and tolerances.

- Identifying and correcting any non-conforming products.

Interview Tips

Preparing for a Wood Mechanist interview can help you showcase your skills and increase your chances of success. Here are some helpful interview tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Wood Mechanist position you are applying for. This will demonstrate your interest in the opportunity and help you tailor your answers to the company’s needs.

- Visit the company website to learn about their products, services, and company culture.

- Review the job description to identify the key responsibilities and qualifications required for the role.

2. Highlight Your Skills and Experience

During the interview, emphasize your technical skills and experience as a Wood Mechanist. Provide specific examples of your proficiency in operating different types of woodworking machinery and your ability to produce high-quality products.

- Describe your experience in setting up and calibrating woodworking machines.

- Share examples of your problem-solving abilities in troubleshooting and resolving machine issues.

3. Demonstrate Your Safety Awareness

Woodworking involves the use of potentially hazardous machinery. In the interview, stress your strong safety awareness and adherence to safety protocols. Explain how you prioritize safety in your work environment.

- Describe your understanding of workplace safety regulations and industry best practices.

- Provide examples of how you ensure your own safety and the safety of those around you.

4. Show Your Motivation and Passion

Woodworking requires a combination of technical skills and passion for the craft. In the interview, show your enthusiasm for the profession and your desire to contribute to the company’s success.

- Express your interest in the company’s products and how you would like to use your skills to contribute.

- Discuss your hobbies or personal projects related to woodworking, demonstrating your commitment to the field.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wood Mechanist role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.