Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wood Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

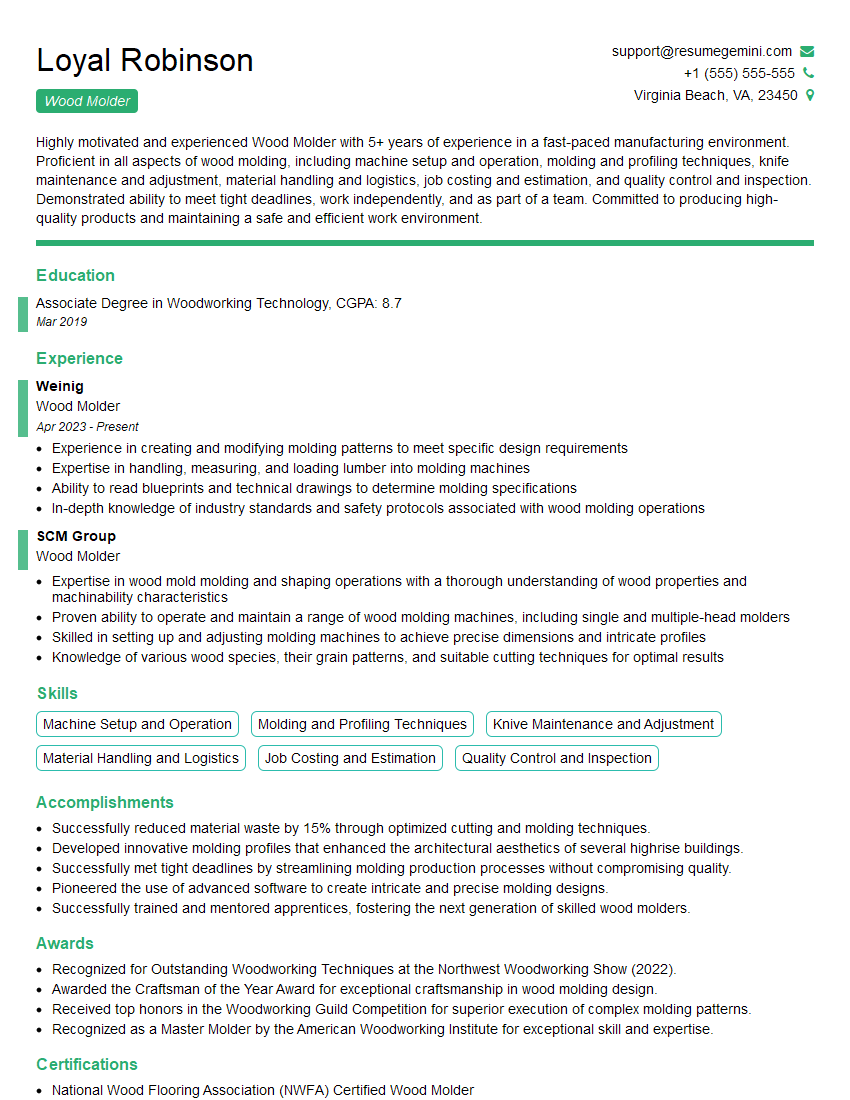

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Molder

1. What essential safety precautions should be followed when using a wood molder?

- Wear appropriate safety gear like safety glasses, hearing protection, and a dust mask.

- Inspect the machine thoroughly before use, checking for any loose parts or damage.

- Securely clamp the wood piece to the worktable to prevent it from moving during the molding process.

- Keep hands away from the cutter head and always use push sticks or blocks to guide the wood through the machine.

- Be aware of the direction of the cutter head rotation to avoid kickback.

2. Explain the process of setting up and operating a wood molder to achieve specific molding profiles.

Selecting the Cutter Head and Profile Knives

- Choose the appropriate cutter head for the desired molding profile.

- Install the profile knives in the correct sequence and ensure they are properly aligned and secured.

Adjusting the Feed Rate and Fence Position

- Set the feed rate according to the wood species and molding complexity.

- Adjust the fence position to control the depth of cut and the width of the molding.

Running the Woodpiece

- Securely clamp the woodpiece to the worktable.

- Feed the woodpiece through the machine while maintaining a firm grip on the push sticks.

- Monitor the molding process and make necessary adjustments as required.

3. How do you maintain the sharpness of the cutter head knives and ensure their optimal performance?

- Regularly sharpen the knives using a sharpening stone or a grinding machine.

- Inspect the knives for any damage or wear, and replace them if necessary.

- Clean the knives and the cutter head after each use to remove any wood shavings or resin buildup.

- Apply a light coat of lubricant to the knives to reduce friction and extend their lifespan.

4. Describe the different types of wood molders and their specific applications.

- Single-Head Molder: Used for basic molding profiles on smaller workpieces.

- Multi-Head Molder: Capable of creating complex molding profiles with multiple cutter heads.

- High-Speed Molder: Designed for high-volume production of moldings at faster feed rates.

- CNC Molder: Computer-controlled molder that allows for precise and intricate molding operations.

5. Explain the importance of grain direction when molding wood and how it affects the quality of the finished product.

- Molding with the grain direction reduces the risk of tear-out and improves the strength of the molding.

- Molding against the grain can result in chipping, splintering, and a weaker finished product.

- Identifying the grain direction of the wood is essential for selecting the appropriate feed direction and minimizing defects.

6. Describe the process of troubleshooting common issues that may arise during wood molding and how to resolve them.

Kickback

- Check the cutter head rotation direction and ensure it matches the feed direction.

- Use sharp knives and feed the woodpiece at an appropriate rate.

Tear-out

- Mold with the grain direction.

- Use a backer board to support the woodpiece during molding.

Uneven Molding

- Inspect the cutter head knives for damage or misalignment.

- Adjust the fence position to ensure a consistent depth of cut.

7. Explain the importance of maintenance and calibration in ensuring the accuracy and efficiency of a wood molder.

- Regular maintenance prevents breakdowns and extends the lifespan of the machine.

- Calibration ensures precise molding dimensions and consistent performance.

- Following manufacturer’s maintenance and calibration guidelines is crucial for optimal machine operation.

8. Describe the different types of wood molding cutters and their specific uses.

Beading Cutters

- Create rounded or semi-circular molding profiles.

- Used for decorative trim, picture frames, and furniture details.

Ogee Cutters

- Create S-shaped profiles with a concave and convex curve.

- Used for crown molding, baseboards, and chair rails.

Cove Cutters

- Create concave profiles with a curved bottom.

- Used for decorative trim, cabinetry, and architectural details.

9. Explain the concept of “back molding” and its applications in woodworking.

- Back molding is a technique where a reverse or complementary molding profile is created on the backside of a woodpiece.

- Used to create decorative effects, enhance structural strength, and hide unsightly joints.

- Applications include picture frames, cabinet doors, and furniture pieces.

10. Describe your experience in using specialized attachments or accessories with a wood molder, such as sanding heads or profiling attachments.

Sanding Heads

- Used for sanding and smoothing the surface of the molding.

- Can be used to refine the profile or remove imperfections.

Profiling Attachments

- Allow for the creation of intricate or custom molding profiles.

- Used in conjunction with dedicated cutter heads to produce unique and specialized moldings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wood Molder is responsible for operating a wood molding machine to create various shapes. Some of the key job responsibilities include:1. Machine Operation

Loading wood into the molding machine and ensuring it’s properly aligned and secured.

- Setting up and calibrating the machine according to the required specifications.

- Operating the machine to produce moldings of the desired shape and size.

2. Quality Control

Inspecting moldings for quality and accuracy.

- Noticing any defects or inconsistencies and taking corrective action.

- Making adjustments to the machine or process to maintain quality standards.

3. Maintenance and Troubleshooting

Keeping the molding machine clean and well-maintained.

- Performing routine maintenance and cleaning tasks.

- Troubleshooting any operational issues and making necessary repairs.

4. Safety and Compliance

Ensuring adherence to safety protocols.

- Wearing appropriate safety gear and following safety procedures.

- Complying with all applicable workplace regulations and standards.

Interview Tips

Preparation and practice are key to acing a job interview. Here are some tips to help you succeed:

1. Research the Company and Position

Demonstrate your interest and enthusiasm by learning about the company’s mission, values, and products or services.

- Go through the company website and social media profiles.

- Read industry news and articles to stay updated on the latest trends.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and why you’re interested in the position.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice answering questions aloud to improve your delivery and confidence.

3. Showcase Your Technical Skills

Highlight your proficiency in operating wood molding machines.

- Provide examples of projects or experience where you successfully produced moldings.

- Discuss your knowledge of different types of wood and molding techniques.

4. Emphasize Your Attention to Detail

Wood molding requires precision and attention to detail.

- Give examples of your ability to inspect products for defects and meet quality standards.

- Describe your approach to ensuring accuracy and consistency in your work.

5. Dress Professionally and Arrive Punctually

First impressions matter.

- Dress in business attire that is clean and well-fitting.

- Arrive on time for your interview to show respect and punctuality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!