Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wood Pattern Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wood Pattern Maker so you can tailor your answers to impress potential employers.

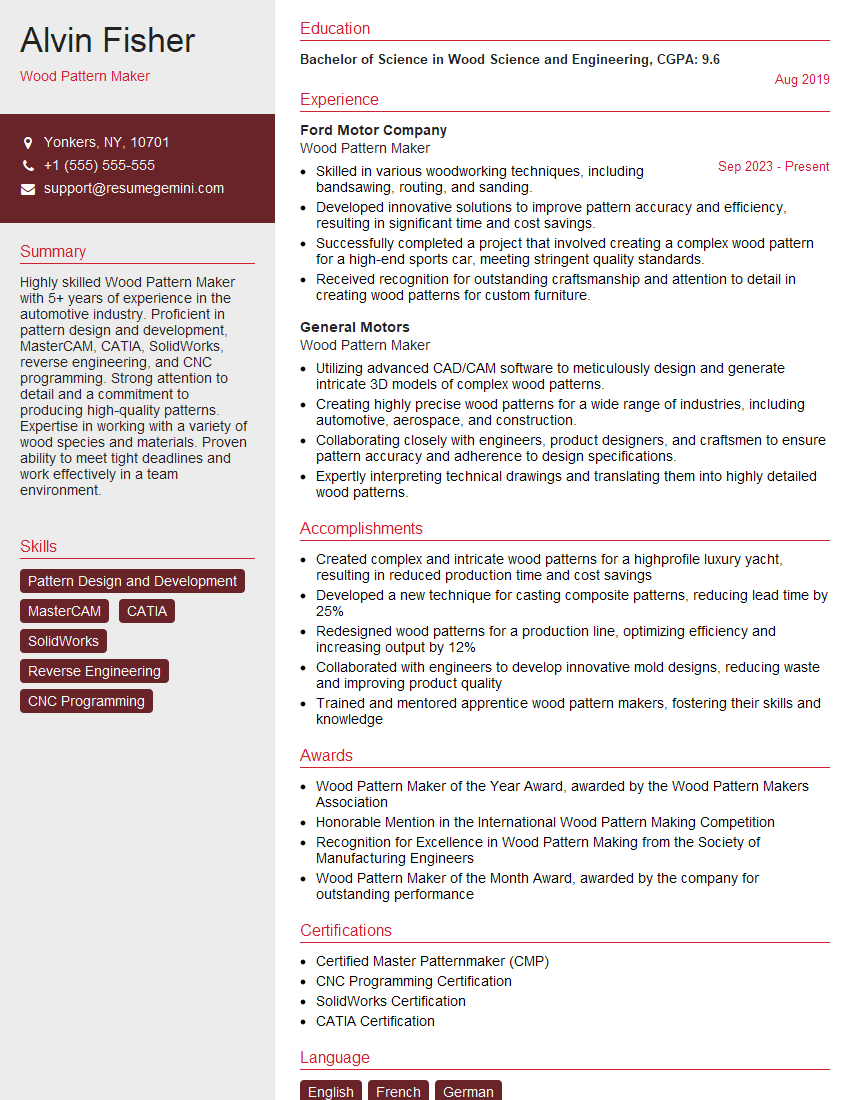

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Pattern Maker

1. How do you ensure the accuracy and precision of wood patterns?

To ensure the accuracy and precision of wood patterns, I employ a multi-step process:

- Detailed planning: I start by carefully reviewing the design specifications and creating detailed drawings.

- Precise measurements: Using calibrated measuring tools, I take precise measurements of all dimensions, ensuring adherence to specifications.

- Careful selection of materials: I select high-quality wood and other materials that meet the required specifications for strength, stability, and resistance to warping.

- Proper joinery techniques: I employ strong and durable joinery techniques, such as dovetail joints, to ensure the structural integrity of the pattern.

- Thorough inspection: Throughout the process, I conduct regular inspections to identify and correct any deviations from the design.

2. What types of joinery techniques are most commonly used in wood pattern making?

Strong and Durable Joints

- Dovetail joints: These interlocking joints provide exceptional strength and resistance to shear forces.

- Mortise and tenon joints: These joints connect perpendicular members, providing a secure and durable connection.

Adaptable Joints

- Dowel joints: These simple yet effective joints use dowels to align and reinforce the connection.

- Biscuit joints: These joints use oval-shaped biscuits to create a strong and concealed connection.

Specialized Joints

- Finger joints: These interlocking joints provide a strong and aesthetically pleasing connection.

- Box joints: These joints create a strong and durable connection with a decorative appearance.

3. What are the key considerations for selecting the right wood for a wood pattern?

When selecting the right wood for a wood pattern, I consider the following key factors:

- Strength and durability: The wood should have adequate strength and durability to withstand the rigors of handling and casting.

- Stability: The wood should be dimensionally stable, resisting warping and shrinking over time.

- Workability: The wood should be easy to machine, shape, and join, allowing for precise and efficient pattern making.

- Cost: The cost of the wood should be within the project budget.

- Availability: The wood should be readily available and in sufficient quantities.

4. What are the different types of molding used in wood pattern making and their applications?

There are various types of molding used in wood pattern making, each with specific applications:

- Crown molding: Used to create decorative transitions between walls and ceilings.

- Base molding: Used to cover the joint between the wall and floor, providing a finished look.

- Casing molding: Used to frame windows, doors, and other openings.

- Chair rail molding: Used to protect the wall from damage caused by chair backs.

- Picture frame molding: Used to create custom frames for pictures and artwork.

5. How do you ensure the proper alignment and spacing of pattern components?

Ensuring proper alignment and spacing of pattern components is crucial for successful casting. I employ several techniques:

- Precise measurements: I take accurate measurements and use jigs and templates to ensure consistent alignment.

- Parallel lines and perpendicular angles: I use precision tools to create parallel lines and perpendicular angles, ensuring the proper orientation of pattern components.

- Reference points: I establish reference points on the pattern and use them to align and space components accurately.

- Assembly fixtures: I may use custom assembly fixtures to hold and align pattern components during assembly.

6. What is the relationship between pattern shrinkage and casting accuracy?

Pattern shrinkage refers to the reduction in size or shape of a pattern over time due to changes in temperature and humidity.

- Effects on casting accuracy: Pattern shrinkage can have a significant impact on casting accuracy by altering the dimensions of the pattern and, consequently, the casting.

- Compensation techniques: To compensate for pattern shrinkage, I often adjust the dimensions of the pattern slightly larger than the desired final casting size.

- Alignment and spacing: I monitor and adjust the alignment and spacing of pattern components to minimize the impact of pattern shrinkage on casting accuracy.

7. How do you ensure the durability and longevity of wood patterns?

To ensure the durability and longevity of wood patterns, I follow these best practices:

- Proper storage: I store patterns in a climate-controlled environment to minimize warping, shrinking, and damage.

- Protective coatings: I apply protective coatings, such as shellac or polyurethane, to protect the surface of the pattern from moisture, stains, and wear.

- Regular maintenance: I conduct regular inspections and perform necessary maintenance, such as repairing any damage or loose joints.

- Handling precautions: I handle patterns carefully to avoid damage and maintain their accuracy.

8. What are the advantages of using composite materials in wood pattern making?

Composite materials offer several advantages in wood pattern making:

- Dimensional stability: Composite materials have low moisture absorption and are less prone to warping and shrinking than wood.

- Durability: Composites are highly durable and resistant to wear, impact, and chemicals.

- Workability: Composite materials can be easily machined and shaped, allowing for intricate designs.

- Cost-effectiveness: In some cases, composite materials can be more cost-effective than traditional wood patterns.

9. What are the key qualities of a successful wood pattern maker?

Successful wood pattern makers possess a combination of skills and qualities:

- Technical expertise: In-depth knowledge of wood pattern making techniques, materials, and equipment.

- Attention to detail: Meticulous attention to accuracy and precision in all aspects of pattern making.

- Problem-solving abilities: Ability to anticipate and overcome challenges in pattern design and construction.

- Communication skills: Effective communication to convey technical information and collaborate with other professionals.

- Teamwork: Collaborative and supportive teamwork skills to contribute to project success.

10. How do you stay updated with the latest advancements in wood pattern making technology?

To stay updated with the latest advancements in wood pattern making technology, I engage in the following practices:

- Industry events and conferences: Attend industry events and conferences to learn about emerging technologies and best practices.

- Trade publications: Read trade publications and online resources to stay informed about new materials, equipment, and techniques.

- Online courses and training: Participate in online courses and training programs to enhance my skills and knowledge.

- Collaboration with experts: Connect with experienced wood pattern makers and industry professionals to exchange knowledge and ideas.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Pattern Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Pattern Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Pattern Makers play a crucial role in the manufacturing process of intricate metal castings. Their primary responsibility is to design, construct, and maintain wooden patterns that serve as molds for creating metal parts.

1. Pattern Design and Development

Wood Pattern Makers collaborate closely with engineers and designers to develop patterns that precisely match the specifications of the desired metal castings. They leverage their knowledge of wood properties and machining techniques to create patterns that are both durable and functional.

- Interpret blueprints, sketches, and engineering drawings.

- Conduct thorough research on wood materials and their suitability for specific applications.

- Design and create detailed plans for wooden patterns, considering factors such as grain orientation and shrinkage.

2. Pattern Construction

Once the pattern designs are finalized, Wood Pattern Makers meticulously construct the physical patterns using various woodworking tools and machinery. Precision and accuracy are paramount at this stage to ensure that the patterns meet the exact specifications.

- Utilize hand and power tools, such as saws, planers, and sanders.

- Follow strict dimensional tolerances and quality control measures.

- Handle and store patterns with care to prevent any damage.

3. Pattern Maintenance and Repair

Wood Pattern Makers are responsible for maintaining and repairing patterns to ensure they continue to produce high-quality metal castings. This involves inspecting patterns for wear and tear, making necessary repairs, and performing regular maintenance to extend their lifespan.

- Conduct routine inspections and identify potential issues.

- Repair damaged patterns, replace worn-out components.

- Monitor patterns during use and make adjustments if necessary.

4. Quality Control and Documentation

Wood Pattern Makers play a vital role in ensuring the quality of the final metal castings. They inspect patterns to ensure they meet specifications, perform quality control checks, and document their findings. This helps identify and prevent any potential defects in the casting process.

- Inspect patterns regularly, check dimensions and tolerances.

- Document all quality checks and inspection findings.

- Communicate any deviations from specifications to relevant personnel.

Interview Tips

In addition to possessing a solid understanding of the job responsibilities, candidates preparing for a Wood Pattern Maker interview can enhance their chances of success by following some key tips:

1. Research the Company and Industry

Thoroughly research the company you are applying to and the overall industry. This will demonstrate your interest in the position and enable you to ask insightful questions during the interview.

- Visit the company’s website and social media profiles.

- Read industry publications and news to gain an understanding of current trends and challenges.

2. Highlight Your Skills and Experience

Clearly articulate your relevant skills and experience in your resume and during the interview. Showcase your proficiency in design, construction, and maintenance of wooden patterns. Provide specific examples of your work and the outcomes you achieved.

- Quantify your accomplishments whenever possible, using specific metrics and numbers.

- Demonstrate your understanding of different types of wood and machining techniques.

3. Prepare Industry-Specific Questions

Asking thoughtful questions related to the industry and the company’s specific requirements indicates your genuine interest. It also gives you an opportunity to clarify any aspects of the role or the company’s operations.

- Inquire about the company’s casting process and the types of patterns they typically work with.

- Ask about the company’s commitment to quality control and customer satisfaction.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic demeanor. Show genuine interest in the position and express your passion for the craft of pattern making. Remember to dress professionally and arrive on time for the interview.

- Start the interview with a firm handshake and a smile.

- Maintain eye contact and actively listen to the interviewer’s questions.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wood Pattern Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wood Pattern Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.