Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wood Preserving Plant Laborer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wood Preserving Plant Laborer so you can tailor your answers to impress potential employers.

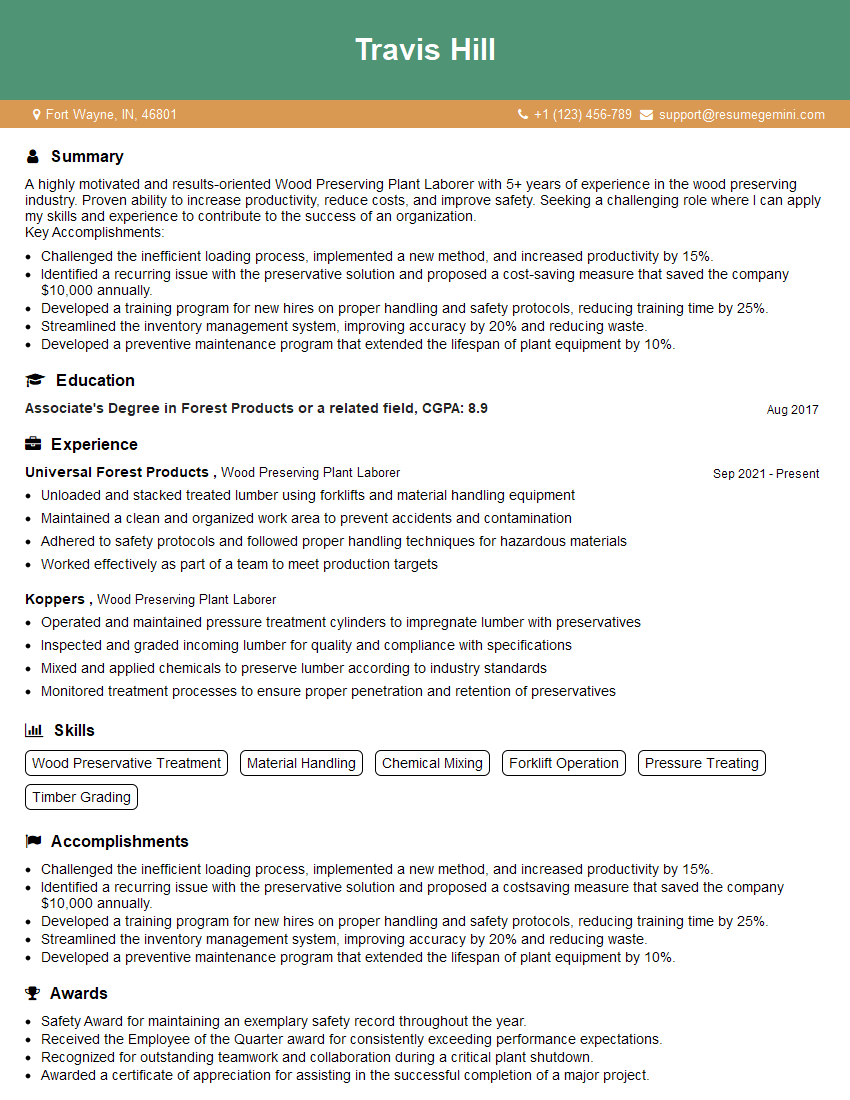

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Preserving Plant Laborer

1. What is the process of wood preservation?

Wood preservation involves treating wood with chemicals to protect it from decay and insects. The process typically includes the following steps:

- Preparation: The wood is prepared by removing bark and other debris, and cutting it to the desired size.

- Treatment: The wood is treated with a preservative, which may be applied by soaking, spraying, or brushing.

- Drying: The treated wood is dried to remove excess preservative.

- Conditioning: The treated wood is conditioned to stabilize its moisture content and prevent warping.

2. What are the different types of wood preservatives?

- Creosote: A heavy oil that is effective against decay and insects, but has a strong odor.

- Pentachlorophenol (PCP): A synthetic chemical that is effective against decay and insects, but is toxic to humans and animals.

- Copper naphthenate: A copper-based preservative that is effective against decay and insects, but is not as toxic as PCP.

- Ammoniacal copper zinc arsenate (ACZA): A water-based preservative that is effective against decay and insects, but is restricted for use on certain types of wood.

- Borates: Water-soluble chemicals that are effective against decay and insects, but are not as durable as other preservatives.

3. What are the safety precautions that must be taken when working with wood preservatives?

When working with wood preservatives, it is important to take the following safety precautions:

- Wear protective clothing, including gloves, goggles, and a respirator.

- Avoid contact with skin and eyes.

- Do not ingest wood preservatives.

- Work in a well-ventilated area.

- Follow all manufacturer’s instructions.

4. What are the different types of wood treating equipment?

- Pressure treating: A process in which wood is treated under pressure with a preservative.

- Vacuum treating: A process in which wood is treated under vacuum with a preservative.

- Steaming treating: A process in which wood is treated with steam before being treated with a preservative.

- Soaking treating: A process in which wood is soaked in a preservative.

- Brushing treating: A process in which a preservative is applied to the surface of the wood with a brush.

5. What is the quality control process for wood preservation?

The quality control process for wood preservation typically includes the following steps:

- Inspection of wood: The wood is inspected to ensure that it is free of defects.

- Treatment of wood: The wood is treated with a preservative in accordance with the manufacturer’s instructions.

- Drying of wood: The treated wood is dried to remove excess preservative.

- Conditioning of wood: The treated wood is conditioned to stabilize its moisture content and prevent warping.

- Testing of wood: The treated wood is tested to ensure that it meets the required standards.

6. What are the environmental concerns associated with wood preservation?

The environmental concerns associated with wood preservation include the following:

- Pollution of water and soil: Wood preservatives can leach into water and soil, contaminating these resources.

- Air pollution: Wood preservatives can release volatile organic compounds (VOCs) into the air, contributing to air pollution.

- Human health: Wood preservatives can be harmful to human health if they are ingested, inhaled, or absorbed through the skin.

7. What are the different types of wood used in wood preservation?

- Softwoods: Softwoods are typically used for construction and other outdoor applications. Examples of softwoods include pine, fir, and spruce.

- Hardwoods: Hardwoods are typically used for furniture and other indoor applications. Examples of hardwoods include oak, maple, and mahogany.

- Tropical hardwoods: Tropical hardwoods are typically used for outdoor applications where durability is required. Examples of tropical hardwoods include teak, mahogany, and ipe.

8. What is the difference between treated and untreated wood?

- Treated wood: Treated wood has been treated with a preservative to protect it from decay and insects.

- Untreated wood: Untreated wood has not been treated with a preservative and is therefore susceptible to decay and insects.

9. What are the advantages and disadvantages of treated wood?

Advantages of treated wood:

- Durability: Treated wood is more durable than untreated wood and can last for many years.

- Resistance to decay and insects: Treated wood is resistant to decay and insects, making it a good choice for outdoor applications.

- Low maintenance: Treated wood requires less maintenance than untreated wood.

Disadvantages of treated wood:

- Cost: Treated wood is more expensive than untreated wood.

- Environmental concerns: Treated wood contains chemicals that can be harmful to the environment.

- Safety concerns: Treated wood can be harmful to human health if it is not handled properly.

10. What are the applications of wood preservation?

- Construction: Treated wood is used in a wide variety of construction applications, including decks, fences, and siding.

- Landscaping: Treated wood is used in landscaping applications, including mulch, raised beds, and pathways.

- Marine: Treated wood is used in marine applications, including docks, piers, and pilings.

- Industrial: Treated wood is used in industrial applications, including pallets, crates, and railroad ties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Preserving Plant Laborer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Preserving Plant Laborer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Preserving Plant Laborers play a crucial role in ensuring the smooth and efficient operation of wood preserving facilities. Their responsibilities encompass a wide range of tasks, including:

1. Lumber Handling and Preparation

Receiving and unloading incoming lumber, ensuring proper storage

- Inspecting lumber for quality and defects

- Preparing lumber for treatment, including cutting, shaping, and cleaning

2. Treatment Process

Operating and monitoring wood treatment equipment, such as pressure vessels and kilns

- Loading and unloading lumber into and out of treatment chambers

- Maintaining records and logs of treatment parameters

3. Quality Assurance

Inspecting treated lumber for proper penetration and adherence to specifications

- Conducting quality control tests, such as borax retention assays

- Ensuring compliance with environmental and safety regulations

4. Maintenance and Housekeeping

Cleaning and maintaining equipment, work areas, and facilities

- Performing minor repairs and troubleshooting equipment issues

- Maintaining a clean and organized work environment

Interview Tips

Preparing for a job interview can be daunting, but with the right approach, you can present yourself confidently and increase your chances of success. Here are some interview tips and tricks to help you ace your interview for the Wood Preserving Plant Laborer position:

1. Research the Company and Role

Take the time to thoroughly research the company and the specific role you are applying for. Understand their values, mission, and the responsibilities of the position. This knowledge will help you tailor your answers and demonstrate your understanding of the company’s needs.

2. Practice Common Interview Questions

Prepare by practicing answering common interview questions, such as “Tell me about yourself” or “Why are you interested in this role?” These questions are often asked to assess your communication skills and enthusiasm for the position.

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are most relevant to the role. Focus on transferable skills, such as physical strength, attention to detail, and a positive attitude. Use specific examples to demonstrate your abilities.

4. Be Enthusiastic and Positive

Showcase your enthusiasm for the role and your desire to contribute to the team. A positive attitude and a willingness to learn can make a strong impression on the interviewer.

5. Ask Thoughtful Questions

Towards the end of the interview, take the opportunity to ask thoughtful questions that demonstrate your interest in the company and the role. This shows that you are engaged and eager to learn more.

6. Dress Professionally and Be Punctual

First impressions matter! Dress professionally and arrive for your interview on time. This shows respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Preserving Plant Laborer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!