Feeling lost in a sea of interview questions? Landed that dream interview for Wood Scaler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wood Scaler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

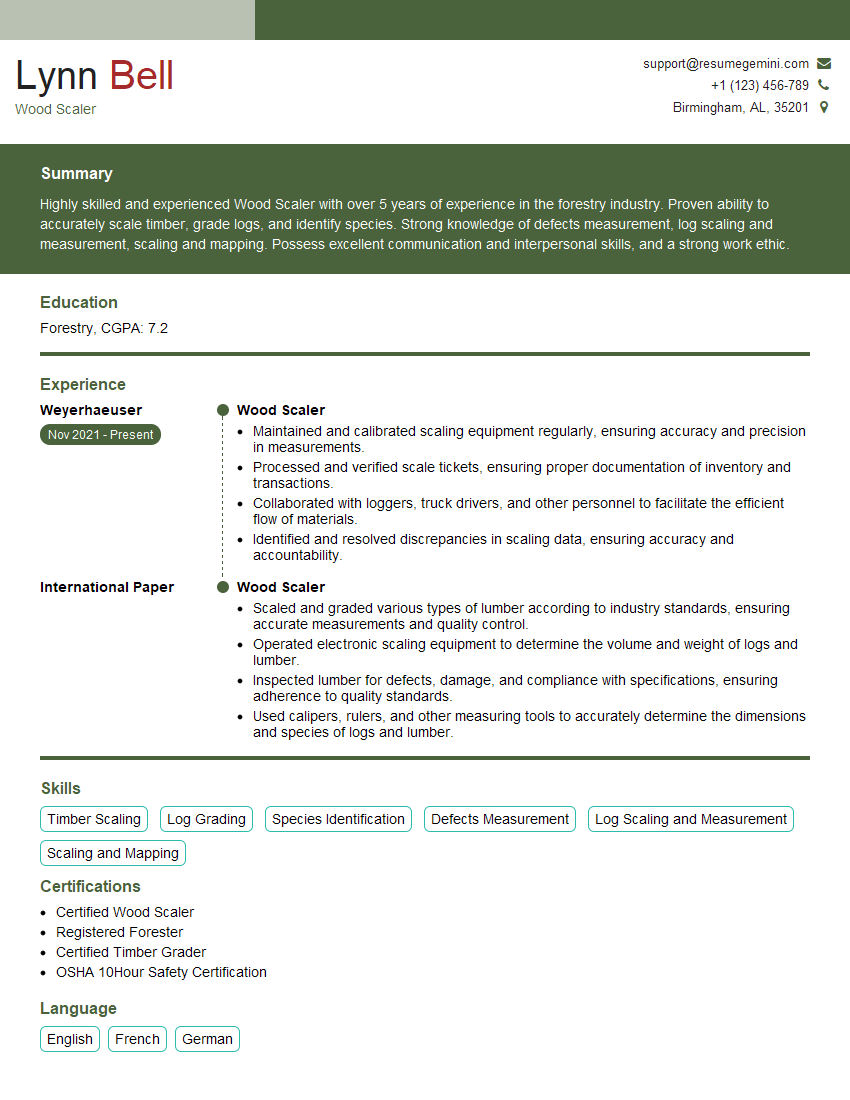

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Scaler

1. What are the different types of wood scalers and their uses?

Answer:

- Linear Wood Scalers: These scalers are used for scaling logs of uniform diameter and length. They are typically used in sawmills and veneer plants.

- Rotary Wood Scalers: These scalers are used for scaling logs of varying diameter and length. They are typically used in pulp and paper mills.

- Optical Wood Scalers: These scalers use computer vision technology to measure the diameter and length of logs. They are typically used in large-scale sawmills and pulp and paper mills.

2. What are the key factors that affect the accuracy of wood scaling?

Factors affecting Wood Scaling

- Log Shape: The shape of the log can affect the accuracy of the scaling. Logs that are tapered or have irregular shapes can be difficult to scale accurately.

- Log Density: The density of the wood can also affect the accuracy of the scaling. Denser woods are more difficult to scale accurately than less dense woods.

- Log Moisture Content: The moisture content of the wood can also affect the accuracy of the scaling. Wet logs are more difficult to scale accurately than dry logs.

Factors affecting Wood Scaler’s work

- Scaler’s Experience: The experience of the scaler can also affect the accuracy of the scaling. More experienced scalers are typically more accurate than less experienced scalers.

- Scaler’s Equipment: The equipment that the scaler uses can also affect the accuracy of the scaling. Well-maintained and calibrated equipment is typically more accurate than poorly maintained and uncalibrated equipment.

3. What are the safety precautions that should be taken when operating a wood scaler?

Answer:

- Wear appropriate safety gear: This includes hard hat, safety glasses, earplugs, and gloves.

- Be aware of your surroundings: Be aware of moving equipment and other hazards in the area.

- Use caution when handling logs: Logs can be heavy and awkward to handle. Use proper lifting techniques and be aware of your surroundings.

- Never operate a wood scaler while under the influence of drugs or alcohol.

- Follow all manufacturer’s instructions for the safe operation of the wood scaler.

4. What are the different methods of wood scaling?

Answer:

- Manual Scaling: This method involves using a tape measure to measure the diameter and length of each log. It is the most accurate method of scaling, but it is also the most time-consuming.

- Automated Scaling: This method uses a computer-controlled machine to measure the diameter and length of each log. It is faster than manual scaling, but it is not as accurate.

- Photo Scaling: This method uses a camera to take pictures of each log. The pictures are then analyzed by a computer to determine the diameter and length of each log. It is the fastest method of scaling, but it is not as accurate as manual or automated scaling.

5. What are the different types of wood scaling reports?

Answer:

- Inventory Reports: These reports show the total volume of wood in a given area. They are used for planning logging operations and for managing forest resources.

- Sale Reports: These reports show the volume of wood that has been sold. They are used for accounting purposes and for tracking the progress of logging operations.

- Cruise Reports: These reports show the volume of wood that is available in a given area. They are used for planning logging operations and for managing forest resources.

6. What are the different types of wood scaling software?

Answer:

- Log Scaling Software: This software is used for measuring the diameter and length of logs. It can be used for manual, automated, and photo scaling.

- Inventory Management Software: This software is used for tracking the volume of wood in a given area. It can be used to generate inventory reports, sale reports, and cruise reports.

- Forest Management Software: This software is used for managing forest resources. It can be used to track the growth and yield of trees, and to plan logging operations.

7. What are the different types of wood scaling equipment?

Answer:

- Tape Measures: Tape measures are used for manual scaling to measure the diameter and length of logs.

- Log Scalers: Log scalers are computer-controlled machines that are used for automated scaling to measure the diameter and length of logs.

- Cameras: Cameras are used for photo scaling to take pictures of each log. The pictures are then analyzed by a computer to determine the diameter and length of each log.

- Computers: Computers are used to run wood scaling software. Wood scaling software can be used for manual, automated, and photo scaling.

8. What are the different types of wood scaling applications?

Answer:

- Inventory Management: Wood scaling is used for inventory management to track the volume of wood in a given area.

- Sale Management: Wood scaling is used for sale management to track the volume of wood that has been sold.

- Cruise Management: Wood scaling is used for cruise management to track the volume of wood that is available in a given area.

- Logging Planning: Wood scaling is used for logging planning to plan logging operations and to track the progress of logging operations.

- Forest Management: Wood scaling is used for forest management to manage forest resources and to track the growth and yield of trees.

9. What are the different types of wood scaling standards?

Answer:

- National Hardwood Lumber Association (NHLA) Rules: These rules are used for scaling hardwood logs in the United States.

- International Log Scaling Rule (ILSR): This rule is used for scaling softwood logs in Canada.

- Scribner Decimal C Log Rule: This rule is used for scaling softwood logs in the United States.

- Doyle Log Rule: This rule is used for scaling softwood logs in the United States.

10. What are the different types of wood scaling certifications?

Answer:

- Certified Log Scaler (CLS): This certification is offered by the National Hardwood Lumber Association (NHLA).

- Registered Professional Forester (RPF): This certification is offered by the Society of American Foresters (SAF).

- Certified Forester (CF): This certification is offered by the American Forest Foundation (AFF).

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Scaler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Scaler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Scalers are responsible for measuring and assessing the volume and quality of logs and timbers, ensuring accurate records and compliance with company standards. Their key responsibilities include:

1. Measurement and Assessment

Measuring logs using scaling sticks or electronic devices to determine their length, diameter, and volume.

- Applying appropriate scaling rules and formulas to calculate the volume of logs and timbers accurately.

- Assessing the logs’ quality, including grade, species, and defects, to determine their value and marketability.

2. Record Keeping and Reporting

Maintaining accurate records of measurements, assessments, and other relevant data.

- Preparing reports summarizing the quality and quantity of logs scaled, identifying any issues or discrepancies.

- Communicating findings to supervisors and other stakeholders to inform decision-making.

3. Quality Control

Monitoring the quality of logs and timbers throughout the scaling process.

- Identifying and reporting any non-conformances or irregularities in the logs or scaling practices.

- Ensuring compliance with company standards and industry regulations.

4. Equipment Maintenance

Maintaining and calibrating scaling equipment to ensure accuracy and precision.

- Conducting regular inspections and repairs to keep equipment in optimal working condition.

- Following safety protocols and operating procedures.

Interview Tips

To ace the interview and showcase your skills as a Wood Scaler, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s operations, the industry standards, and current trends. This shows your interest and enthusiasm for the role.

- Visit the company’s website to learn about their products, services, and mission.

- Read industry publications and attend webinars to stay informed about best practices and advancements.

2. Highlight Your Scaling Experience

Emphasize your skills in measuring and assessing logs and timbers. Provide specific examples of your accuracy and efficiency.

- Quantify your accomplishments, such as reducing measurement errors by a certain percentage.

- Describe your experience using different scaling methods and equipment.

3. Showcase Your Quality Assurance Skills

Discuss your ability to maintain quality standards and identify non-conformances. Highlight your attention to detail and commitment to accuracy.

- Provide examples of how you implemented quality control measures to improve the scaling process.

- Explain your understanding of industry standards and regulations related to log scaling.

4. Demonstrate Your Equipment Expertise

Emphasize your proficiency in maintaining and calibrating scaling equipment. Explain your understanding of the equipment’s operation and troubleshooting techniques.

- Describe your experience in calibrating scaling sticks and electronic devices.

- Discuss your knowledge of safety protocols and operating procedures for scaling equipment.

5. Prepare for Behavioral Questions

Be prepared to answer behavioral questions that explore your teamwork, problem-solving, and communication skills.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Provide specific examples that demonstrate your abilities in these areas.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Scaler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!