Feeling lost in a sea of interview questions? Landed that dream interview for Wood Turner but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wood Turner interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

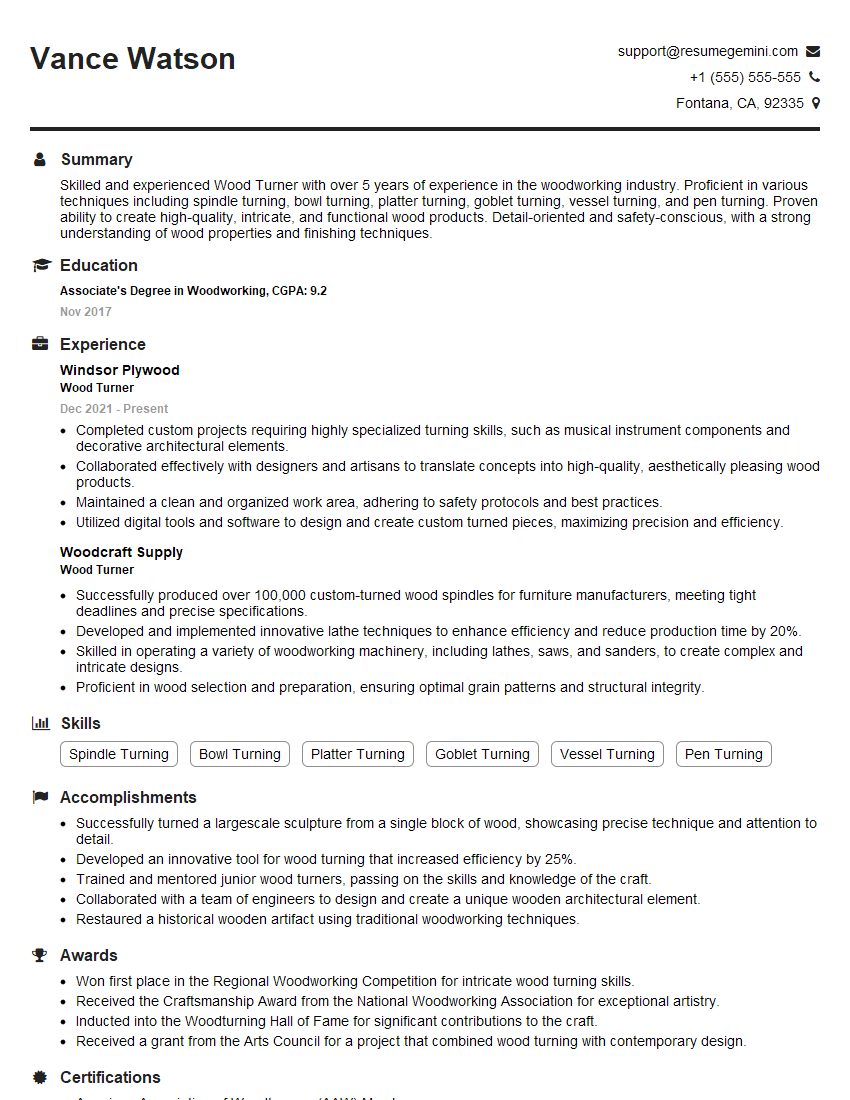

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Turner

1. Explain the different types of woodturning tools and their uses?

- Lathe: The lathe is the main tool used for woodturning. It spins the wood while you use other tools to shape it.

- Chisels: Chisels are used to remove wood from the workpiece. There are many different types of chisels, each with a specific purpose.

- Gouges: Gouges are similar to chisels, but they have a curved blade. They are used to create concave shapes in the wood.

- Scrapers: Scrapers are used to smooth the surface of the wood. They can also be used to create decorative effects.

- Sanders: Sanders are used to sand the wood to a smooth finish. There are many different types of sanders, each with a specific purpose.

2. What are the safety precautions that should be taken when woodturning?

Proper Clothing

- Wear close-fitting clothing that will not get caught in the lathe.

- Avoid wearing loose clothing, jewelry, or long hair that could get caught in the lathe.

Eye Protection

- Always wear safety glasses or goggles when woodturning.

- Wood chips and dust can fly off the lathe at high speeds, so it is important to protect your eyes.

Hand Protection

- Wear gloves when sanding or using other tools that could cause splinters.

- Never put your hands near the lathe while it is spinning.

3. How do you choose the right wood for a particular project?

The type of wood you choose for a project will depend on a number of factors, including the following:

- The purpose of the project: Some woods are better suited for certain purposes than others. For example, hardwoods are more durable and are often used for furniture and flooring, while softwoods are less durable and are often used for framing and other construction purposes.

- The availability of the wood: Some woods are more readily available than others. If you are on a budget, you may need to choose a wood that is less expensive and more readily available.

- The aesthetic appeal of the wood: Some woods have a more attractive appearance than others. If you are making a piece of furniture or other decorative item, you may want to choose a wood that has a beautiful grain pattern or color.

4. What are the different types of woodturning finishes?

- Oil finishes: Oil finishes are a good choice for protecting wood from moisture and wear. They are easy to apply and can be used on both indoor and outdoor projects.

- Varnish finishes: Varnish finishes are a good choice for protecting wood from moisture and wear. They are more durable than oil finishes, but they can be more difficult to apply.

- Lacquer finishes: Lacquer finishes are a good choice for protecting wood from moisture and wear. They are the most durable of the three types of finishes, but they can be the most difficult to apply.

- Wax finishes: Wax finishes are a good choice for protecting wood from moisture and wear. They are easy to apply and can be used on both indoor and outdoor projects.

5. What are some tips for troubleshooting common woodturning problems?

- The lathe is vibrating: This could be caused by a number of factors, including an unbalanced workpiece, a loose tailstock, or a dull tool.

- The tool is chattering: This could be caused by a number of factors, including a dull tool, an incorrect cutting angle, or a loose tool rest.

- The wood is burning: This could be caused by a number of factors, including a dull tool, an incorrect cutting speed, or too much pressure being applied to the tool.

- The workpiece is flying off the lathe: This could be caused by a number of factors, including an unbalanced workpiece, a loose tailstock, or a dull tool.

6. What are some of the most common mistakes that woodturners make?

- Not using sharp tools: Dull tools will not cut cleanly and can cause the wood to tear or burn.

- Not using the correct cutting speed: Cutting at the wrong speed can cause the wood to burn or tear.

- Not using the correct cutting angle: Cutting at the wrong angle can cause the tool to chatter or the wood to tear.

- Not supporting the workpiece properly: Not supporting the workpiece properly can cause it to vibrate or fly off the lathe.

7. What are some of the latest trends in woodturning?

- 3D woodturning: 3D woodturning is a technique that uses a CNC machine to create three-dimensional objects from wood.

- Fractal woodturning: Fractal woodturning is a technique that uses a CNC machine to create fractals, which are self-similar patterns that repeat at different scales.

- Pyrography: Pyrography is a technique that uses a heated tool to burn designs into wood.

- Wood carving: Wood carving is a technique that uses a knife or other sharp tool to carve designs into wood.

8. What are some of the benefits of woodturning?

- It is a relaxing and enjoyable hobby: Woodturning can be a great way to relieve stress and have some fun.

- It is a creative outlet: Woodturning allows you to express your creativity and make unique and beautiful objects.

- It is a rewarding experience: There is a great sense of accomplishment in completing a woodturning project.

- It is a skill that can be used to make useful and beautiful objects: Woodturning can be used to make a variety of objects, including furniture, bowls, vases, and toys.

9. What are some of the challenges of woodturning?

- It can be a dangerous hobby: Woodturning can be dangerous if you do not take proper safety precautions.

- It can be a time-consuming hobby: Woodturning can be a time-consuming hobby, especially if you are working on a large or complex project.

- It can be a physically demanding hobby: Woodturning can be a physically demanding hobby, especially if you are working on a large or complex project.

- It can be an expensive hobby: Woodturning can be an expensive hobby, especially if you need to purchase a lathe and other equipment.

10. What are your favorite types of wood to turn?

I enjoy turning a variety of woods, but I particularly enjoy turning hardwoods such as oak, maple, and cherry. These woods have a beautiful grain pattern and are very durable. I also enjoy turning softwoods such as pine and cedar. These woods are easier to turn and are a good choice for beginners.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Turner is a professional responsible for transforming raw wood pieces into intricate and functional items using a lathe. Here are the key job responsibilities:1. Woodworking Skills

Wood Turners possess exceptional woodworking skills, including the ability to use hand tools and lathes to shape, cut, and sand wood pieces with precision.

- Use manual and automated lathes to create various shapes and designs.

- Operate cutting tools to remove excess wood and create intricate patterns.

- Sand and finish wood surfaces to achieve desired textures and smoothness.

2. Design and Planning

Wood Turners work closely with designers or customers to interpret design concepts and translate them into tangible wood products.

- Follow design specifications to create products with the desired shape, size, and finish.

- Make suggestions for design improvements based on their expertise and experience.

- Develop and implement new techniques to enhance design and production efficiency.

3. Material Selection and Handling

Wood Turners are knowledgeable about different types of wood and their characteristics, enabling them to select the most appropriate wood for each project.

- Identify and select wood suitable for turning based on its grain pattern, hardness, and moisture content.

- Handle and store wood materials properly to prevent damage and maintain quality.

- Dispose of wood waste and byproducts in an environmentally responsible manner.

4. Quality Control and Inspection

Wood Turners ensure that the final products meet the required quality standards and customer specifications.

- Inspect finished products thoroughly for any defects, imperfections, or inconsistencies.

- Make necessary adjustments and repairs to ensure product quality and customer satisfaction.

- Maintain a clean and organized work area to facilitate quality control and safety.

Interview Tips

To ace a Wood Turner interview, candidates should prepare thoroughly and showcase their skills and experience in a compelling manner.

1. Research the Company and Position

Research the company’s history, values, and the specific requirements of the Wood Turner position. This will demonstrate your interest in the company and the role.

- Visit the company’s website and social media pages to gather information.

- Review the job description carefully to identify the key responsibilities and qualifications.

- Consider the company’s industry, products, and target market.

2. Highlight Your Skills and Experience

Prepare specific examples that showcase your woodworking skills, design capabilities, and attention to detail. Quantify your accomplishments whenever possible.

- Describe projects you have completed that demonstrate your technical proficiency and artistic vision.

- Provide examples of how you have used your design skills to improve product functionality or aesthetics.

- Share instances where you have exceeded customer expectations by delivering high-quality products.

3. Show Enthusiasm and Passion

Convey your passion for woodworking and your desire to contribute to the company. Express your excitement about the opportunity and how it aligns with your career goals.

- Discuss your favorite aspects of woodworking and why you enjoy the craft.

- Describe your aspirations to grow as a professional and enhance your skills.

- Explain how your values and work ethic align with the company’s culture.

4. Ask Informed Questions

Asking thoughtful questions not only shows your interest but also gives you an opportunity to assess the company’s culture and opportunities.

- Inquire about the company’s commitment to sustainability and environmental practices.

- Ask about the company’s plans for future product development and innovation.

- Request information about potential career growth opportunities within the company.

5. Practice and Prepare

Practice answering common interview questions aloud. This will help you articulate your thoughts clearly and confidently during the actual interview.

- Prepare answers to questions about your background, skills, and experience.

- Consider questions that may test your technical knowledge of woodworking techniques.

- Role-play interview scenarios with a friend or family member to gain feedback.

Next Step:

Now that you’re armed with the knowledge of Wood Turner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wood Turner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini