Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Woodworking Craftsman interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Woodworking Craftsman so you can tailor your answers to impress potential employers.

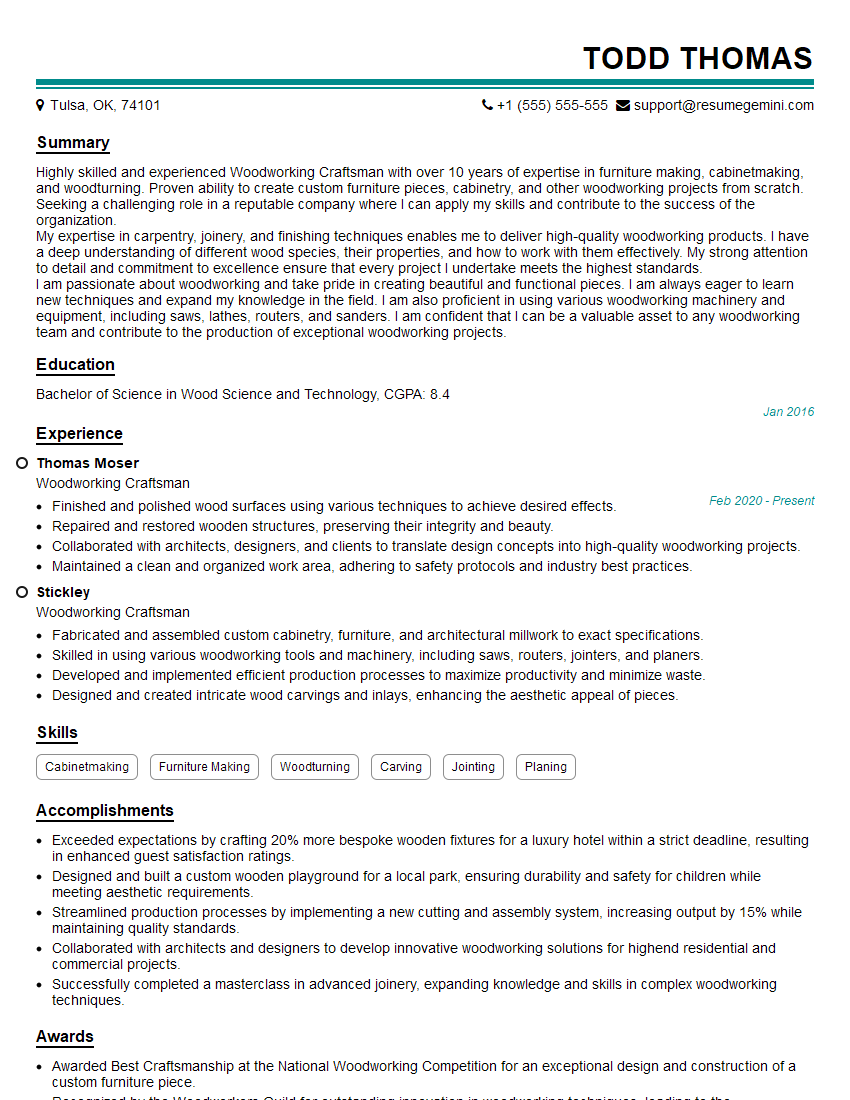

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Woodworking Craftsman

1. What types of joints are commonly used in woodworking?

- Butt joints

- Mitre joints

- Dado joints

- Rabbet joints

- Dovetail joints

2. What is the purpose of using different types of sandpaper grits?

Explain the use of each grit

- Coarse grit (60-80): Used to remove large amounts of material quickly.

- Medium grit (120-150): Used to smooth out surfaces and remove scratches from coarse grit.

- Fine grit (220-240): Used to create a smooth, polished finish.

3. What are the different types of wood finishes, and what are their advantages and disadvantages?

- Oil-based finishes: Durable, water-resistant, and easy to apply. However, they can be slow to dry and emit fumes.

- Water-based finishes: Fast-drying, low-VOC, and easy to clean up. However, they may not be as durable as oil-based finishes.

- Shellac: A natural finish that is easy to apply and dries quickly. However, it is not as durable as other finishes and can be damaged by alcohol.

- Lacquer: A durable, high-gloss finish that is resistant to water and scratches. However, it can be difficult to apply and may require multiple coats.

4. What are the safety precautions that should be taken when working with power tools in a workshop?

- Always wear safety glasses, earplugs, and a dust mask.

- Keep your work area clean and free of clutter.

- Inspect power tools before each use and ensure they are in good working order.

- Never operate power tools while under the influence of alcohol or drugs.

- Be aware of the location of the emergency stop button on all power tools.

5. How do you determine the correct size and type of nails or screws to use for a specific woodworking project?

- Consider the thickness and type of wood being used.

- Determine the strength required for the joint.

- Choose the correct nail or screw size for the thickness of the wood being joined.

- Use the appropriate type of nail or screw for the specific application (e.g., framing nails, finishing nails, drywall screws, etc.).

6. How do you measure and cut angles accurately using a miter saw?

- Set the miter saw to the desired angle.

- Measure and mark the length of the cut on the workpiece.

- Align the workpiece with the saw blade and secure it in place.

- Slowly lower the saw blade onto the workpiece and make the cut.

- Check the accuracy of the cut using a protractor or angle finder.

7. What are the different types of clamps used in woodworking, and what are their specific uses?

- Bar clamps: Used to apply pressure evenly over a long surface.

- C-clamps: Used to hold small pieces of wood in place or to clamp joints.

- Spring clamps: Used to hold small pieces of wood in place or to clamp joints, and are available in a variety of sizes.

- Pipe clamps: Used to clamp large or irregularly shaped pieces of wood.

- Band clamps: Used to clamp large or curved pieces of wood.

8. How do you finish the edges of plywood to prevent them from splintering or delaminating?

- Apply a thin coat of wood glue to the edges of the plywood.

- Seal the edges with a sanding sealer or clear finish.

- Use a router to create a decorative edge on the plywood.

- Apply a strip of veneer or edge banding to the edges of the plywood.

9. What is the difference between a rip cut and a crosscut, and how do you make each type of cut using a circular saw?

- Rip cut: A cut made parallel to the grain of the wood.

- Crosscut: A cut made perpendicular to the grain of the wood.

- To make a rip cut, align the saw blade parallel to the grain of the wood and slowly lower the blade into the workpiece.

- To make a crosscut, align the saw blade perpendicular to the grain of the wood and slowly lower the blade into the workpiece.

10. How do you repair a loose or broken joint in a piece of furniture?

- Identify the type of joint that is loose or broken.

- Disassemble the joint if possible.

- Clean the mating surfaces of the joint and apply wood glue.

- Reassemble the joint and clamp it in place until the glue has dried.

- If the joint is a dowel joint, you may need to replace the broken dowels.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Woodworking Craftsman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Woodworking Craftsman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Woodworking Craftsmen are highly skilled professionals specializing in crafting and repairing wooden structures and furnishings. Their key responsibilities include:

1. Fabrication and Assembly

Using various woodworking equipment and techniques, they design and construct wooden structures, furniture, and other products from scratch. They ensure the accuracy and precision of measurements, cuts, and assembly to meet client specifications.

- Interpreting blueprints and drawings to fabricate custom pieces

- Selecting appropriate wood materials based on durability, aesthetics, and functionality

2. Repair and Restoration

They assess, repair, and restore damaged or worn wooden structures, furniture, and other wooden items. This involves identifying the cause of the damage, selecting appropriate repair techniques, and restoring the items to their original condition.

- Assessing the extent of damage and determining the best course of action

- Using specialized tools and techniques to repair cracks, dents, and other imperfections

3. Finishing and Detailing

They apply various finishes to wooden surfaces to enhance their appearance and protect them from wear and tear. They also add decorative details and moldings to enhance the aesthetic appeal.

- Applying stains, paints, varnishes, and other finishes to protect and enhance wood surfaces

- Creating intricate carvings, moldings, and other decorative elements to add visual interest

4. Quality Control and Inspection

They inspect their work at various stages to ensure accuracy, precision, and compliance with quality standards. They also inspect and verify the work of other craftsmen to maintain a consistent level of quality.

- Adhering to established quality standards and specifications

- Conducting thorough inspections at critical stages to identify and correct any defects

Interview Tips

To ace the interview for a Woodworking Craftsman position, candidates should consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and the specific requirements of the job you’re applying for. This will enable you to tailor your answers and demonstrate your interest in the position.

- Visit the company website to learn about their history, mission, and products

- Study the job description carefully to identify the key skills and qualities required

2. Highlight Your Skills and Experience

Emphasize your proficiency in various woodworking techniques and equipment. Quantify your experience and accomplishments whenever possible to provide concrete evidence of your abilities. Use specific examples to showcase your skills and how they benefit the company.

- Describe your expertise in using different types of woodworking tools and machinery

- Provide examples of projects you’ve completed that demonstrate your craftsmanship and problem-solving abilities

3. Showcase Your Portfolio

If you have a portfolio of your work, bring it to the interview or prepare a digital presentation to showcase your skills. Visual evidence of your craftsmanship can significantly impress the interviewer.

- Include photos or sketches of your previous projects, highlighting the quality of your work

- Be prepared to discuss the techniques and materials used in your portfolio pieces

4. Be Enthuastic and Professional

Demonstrate your passion for woodworking and your commitment to delivering high-quality work. Dress professionally, maintain eye contact, and engage in the interview with enthusiasm and sincerity.

- Share your reasons for pursuing a career in woodworking and what drives your passion

- Ask thoughtful questions to show your interest and understanding of the role

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Woodworking Craftsman interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!