Are you gearing up for a career in Wrap Knitting Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wrap Knitting Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

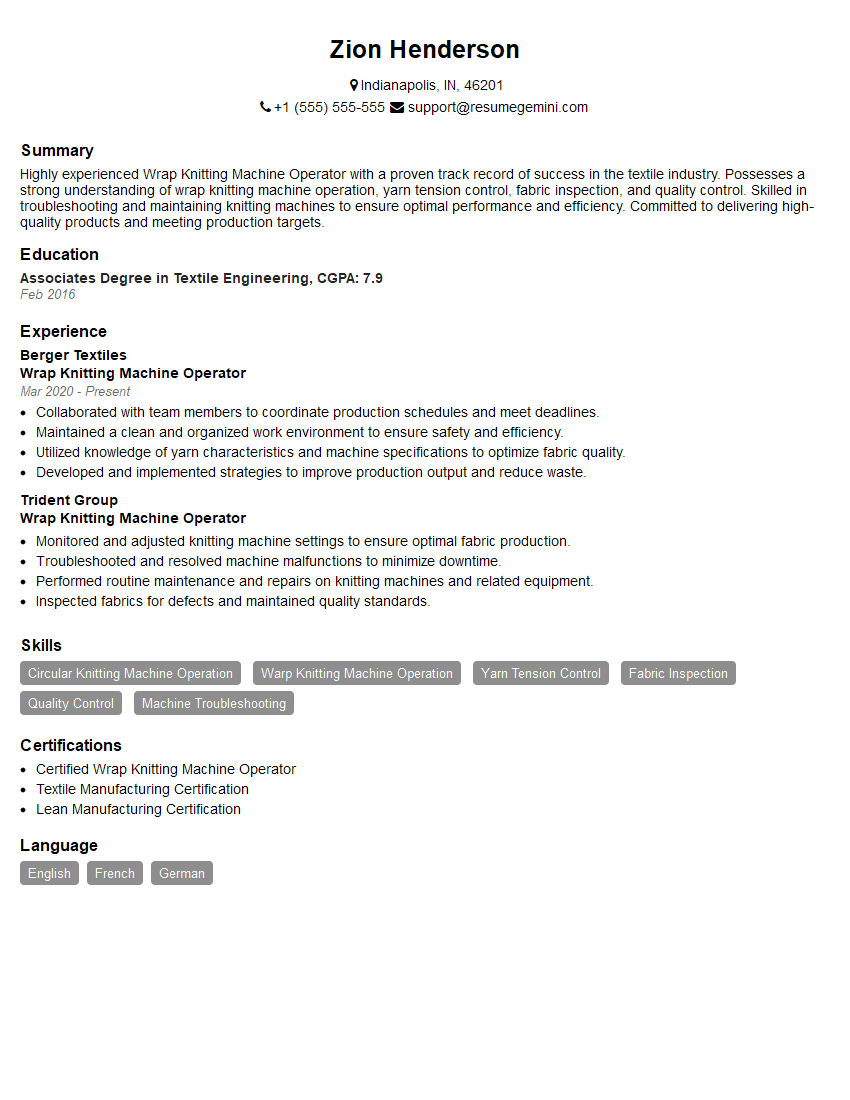

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wrap Knitting Machine Operator

1. Explain the process of preparing a wrap knitting machine for operation?

To prepare a wrap knitting machine for operation, I follow these steps:

- Check the machine for any signs of damage or wear and tear.

- Clean the machine thoroughly, removing any dust or debris.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the needles and yarn guides, making sure they are in good condition.

- Load the yarn onto the machine and thread it through the needles.

- Set the machine to the desired knitting pattern.

- Start the machine and check for any errors.

2. How do you troubleshoot a wrap knitting machine if it is not producing the desired fabric?

Wrong tension

- Check the tension settings and adjust them as needed.

- Check the yarn for any knots or breaks.

- Clean the tension discs.

Needle problems

- Check the needles for any damage or wear and tear.

- Replace any damaged or worn needles.

- Make sure the needles are properly adjusted.

Yarn problems

- Check the yarn for any knots or breaks.

- Replace the yarn if it is damaged.

- Make sure the yarn is properly threaded through the machine.

3. What are the different types of wrap knitting machines and what are their advantages and disadvantages?

- Circular knitting machines: These machines produce a continuous loop of fabric. They are fast and efficient, but they can only produce a limited range of fabrics.

- Flat knitting machines: These machines produce a flat piece of fabric. They are slower and less efficient than circular knitting machines, but they can produce a wider range of fabrics.

- Double-knitting machines: These machines produce a fabric that is double the thickness of a single-knit fabric. They are used to produce fabrics such as sweatshirts and sweatpants.

4. What are the safety precautions that must be followed when operating a wrap knitting machine?

- Wear appropriate safety clothing, including gloves, safety glasses, and earplugs.

- Keep the machine clean and free of debris.

- Never operate the machine with the guards removed.

- Be aware of the moving parts of the machine and keep your hands away from them.

- Stop the machine immediately if you notice any unusual noises or vibrations.

5. How do you maintain a wrap knitting machine to ensure it is in good working order?

- Clean the machine regularly, removing any dust or debris.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the needles and yarn guides regularly for any damage or wear and tear.

- Replace any damaged or worn parts as needed.

- Have the machine serviced by a qualified technician on a regular basis.

6. What are the different types of fabrics that can be produced on a wrap knitting machine?

- Single jersey

- Double jersey

- Rib

- Interlock

- Jacquard

7. What is the difference between a wrap knitting machine and a weft knitting machine?

- Wrap knitting machines knit fabric by wrapping the yarn around a series of needles. This creates a loop of yarn that is then drawn through the previous loop to form a stitch.

- Weft knitting machines knit fabric by inserting a weft yarn through a series of loops. This creates a stitch that is perpendicular to the direction of the yarn.

8. What are the advantages of using a wrap knitting machine?

- Wrap knitting machines are fast and efficient.

- They can produce a wide range of fabrics.

- They are relatively easy to operate.

9. What are the disadvantages of using a wrap knitting machine?

- Wrap knitting machines can be expensive.

- They require regular maintenance.

- They can produce only a limited range of fabrics.

10. What are the career opportunities for a wrap knitting machine operator?

- Production supervisor

- Quality control inspector

- Machine mechanic

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wrap Knitting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wrap Knitting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wrap Knitting Machine Operators are responsible for operating and maintaining wrap knitting machines used in the production of fabrics for various textile applications. Their primary duties include ensuring the smooth operation of the machines, monitoring the quality of the fabric, and troubleshooting any issues promptly. Here are some key job responsibilities of Wrap Knitting Machine Operators:

1. Machine Operation

Set up, operate, and monitor wrap knitting machines to produce fabric according to specifications.

- Thread machines with yarn, check tension, and make any necessary adjustments.

- Monitor machine operation continuously, observing fabric quality and identifying any issues.

2. Fabric Quality Control

Inspect and monitor the quality of the fabric produced by the machine, ensuring it meets required standards.

- Check fabric for defects, such as broken threads, uneven knitting, or color inconsistencies.

- Make adjustments to machine settings or tension to maintain fabric quality.

3. Machine Maintenance

Perform basic maintenance and troubleshooting tasks to keep machines in good working condition.

- Clean and lubricate machines regularly to prevent breakdowns and ensure smooth operation.

- Identify and resolve minor issues, such as thread breaks, tension problems, or sensor malfunctions.

4. Safety and Compliance

Adhere to safety regulations and industry standards while operating wrap knitting machines.

- Wear appropriate safety gear and follow established safety procedures.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help Wrap Knitting Machine Operator candidates ace their interviews:

1. Research the Company and Position

Take the time to learn about the company’s history, culture, and products. This will help you understand their needs and how your skills align with the Wrap Knitting Machine Operator position.

2. Practice Common Interview Questions

Prepare for common interview questions about your experience, skills, and motivations. Practice your answers to ensure they are clear, concise, and highlight your qualifications for the role.

3. Showcase Your Machine Expertise

Emphasize your technical knowledge and experience in operating wrap knitting machines. Describe your understanding of machine mechanics, fabric quality control, and maintenance procedures.

4. Highlight Your Attention to Detail

Wrap Knitting Machine Operators must have a keen eye for detail to ensure the quality of the fabric produced. In your interview, provide examples of your ability to identify defects and make necessary adjustments to maintain high standards.

5. Demonstrate Problem-Solving Skills

Highlight your ability to troubleshoot and resolve machine issues effectively. Describe situations where you identified problems, analyzed causes, and implemented solutions to minimize downtime and maintain productivity.

6. Ask Informed Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more about the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wrap Knitting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.