Are you gearing up for a career in Wrap Turner? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wrap Turner and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

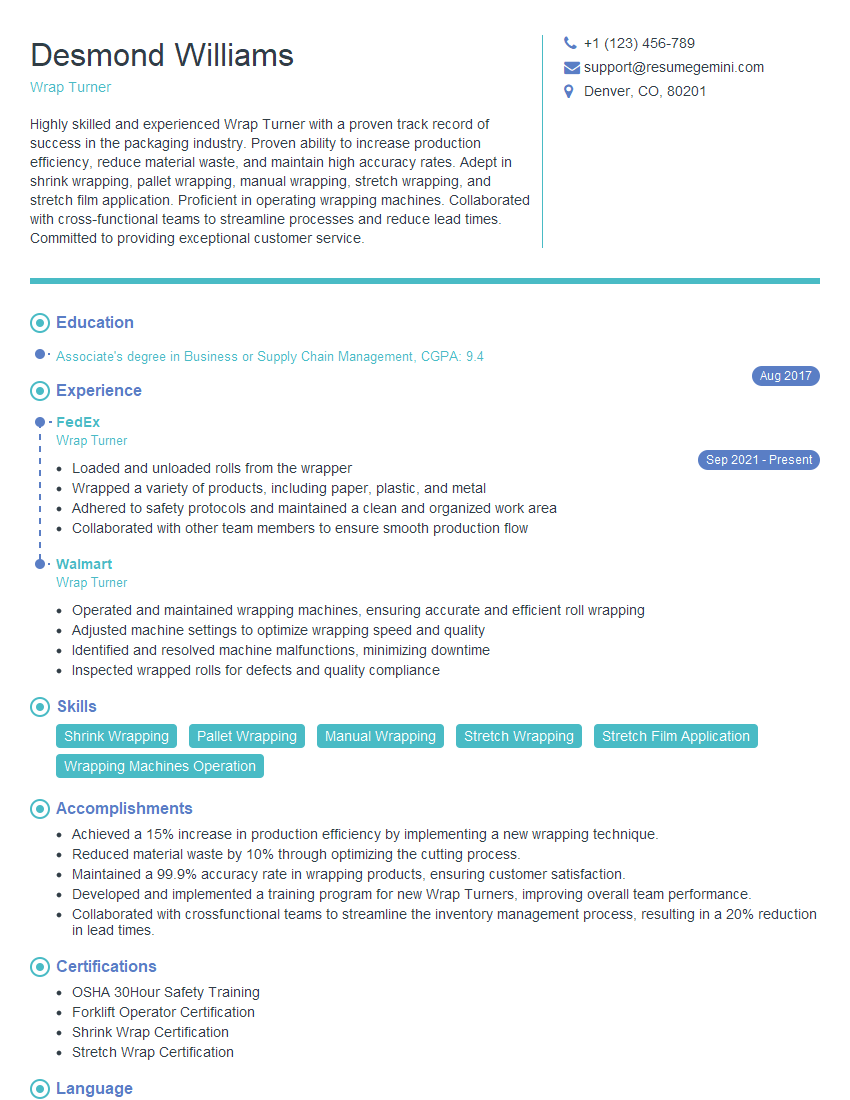

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wrap Turner

1. What are the different types of wrapping machines used in the industry?

- Manual wrapping machines: These machines are operated by hand and require the operator to manually wrap the product.

- Semi-automatic wrapping machines: These machines are partially automated and require the operator to load and unload the product. The machine then wraps the product automatically.

- Fully automatic wrapping machines: These machines are completely automated and do not require any operator intervention. The product is loaded onto the machine and the machine wraps the product automatically.

2. What are the key factors to consider when selecting a wrapping machine?

Factors to consider when selecting a wrapping machine:

- The type of product being wrapped

- The size and shape of the product

- The speed at which the product needs to be wrapped

- The budget for the machine

Other factors to consider:

- The reliability of the machine

- The ease of use of the machine

- The availability of service and support for the machine

3. What are the common problems that can occur with wrapping machines?

- The machine is not wrapping the product properly. This can be caused by a number of factors, such as the wrong type of wrap material being used, the machine not being properly calibrated, or the product being too large or too small for the machine.

- The machine is not running smoothly. This can be caused by a number of factors, such as the machine being overloaded, the belts or gears being worn, or the machine not being properly lubricated.

- The machine is making excessive noise. This can be caused by a number of factors, such as the machine being overloaded, the belts or gears being worn, or the machine not being properly lubricated.

4. How can you troubleshoot and resolve common problems with wrapping machines?

- Check the wrap material. Make sure that the wrap material is the correct type and size for the machine.

- Calibrate the machine. Follow the manufacturer’s instructions to calibrate the machine.

- Check the product size. Make sure that the product is the correct size for the machine.

- Check the machine for overloading. Make sure that the machine is not overloaded.

- Check the belts and gears. Make sure that the belts and gears are not worn or damaged.

- Lubricate the machine. Follow the manufacturer’s instructions to lubricate the machine.

5. What are the safety precautions that should be taken when operating a wrapping machine?

- Always wear appropriate safety gear. This includes safety glasses, gloves, and a hard hat.

- Never operate a machine that is not properly guarded.

- Keep your hands and feet clear of moving parts.

- Never reach into a machine that is running.

- Always follow the manufacturer’s instructions for operating the machine.

6. What are the different types of wrapping materials that can be used?

- Polyethylene (PE) film: This is a thin, flexible plastic film that is commonly used for wrapping food products.

- Polypropylene (PP) film: This is a stronger and more durable plastic film that is commonly used for wrapping industrial products.

- Polyvinyl chloride (PVC) film: This is a clear plastic film that is commonly used for wrapping food products and industrial products.

- Paper: This is a natural material that is commonly used for wrapping food products and industrial products.

- Foil: This is a thin metal sheet that is commonly used for wrapping food products.

7. What are the advantages and disadvantages of using different types of wrapping materials?

Advantages and disadvantages of using different types of wrapping materials:

- Polyethylene (PE) film: Advantages: low cost, flexible, easy to use. Disadvantages: not very strong, not very durable.

- Polypropylene (PP) film: Advantages: strong, durable, heat-resistant. Disadvantages: more expensive than PE film, not as flexible.

- Polyvinyl chloride (PVC) film: Advantages: clear, strong, durable. Disadvantages: more expensive than PE film, not as flexible.

- Paper: Advantages: natural, biodegradable, recyclable. Disadvantages: not very strong, not very durable.

- Foil: Advantages: strong, durable, heat-resistant. Disadvantages: expensive, not very flexible.

8. How do you ensure that wrapped products are properly sealed?

- Use the correct type of wrapping material. The type of wrapping material used will depend on the product being wrapped.

- Use the correct amount of wrapping material. Too much or too little wrapping material can cause the product to be improperly sealed.

- Apply the wrapping material correctly. The wrapping material should be applied smoothly and evenly.

- Use a heat sealer to seal the wrapping material. A heat sealer will create a strong and durable seal.

- Inspect the sealed product to ensure that it is properly sealed.

9. What are the quality control procedures that you follow to ensure that wrapped products meet customer specifications?

- Inspect the incoming wrapping material.

- Calibrate the wrapping machines.

- Train the operators on the proper wrapping procedures.

- Inspect the wrapped products before they are shipped.

- Keep records of all quality control inspections.

10. What are the latest trends in wrapping technology?

- The use of robotic wrapping machines is increasing. Robotic wrapping machines are more efficient and accurate than manual wrapping machines.

- The use of sustainable wrapping materials is increasing. Sustainable wrapping materials are made from recycled materials and are biodegradable.

- The use of smart wrapping machines is increasing. Smart wrapping machines can monitor the wrapping process and make adjustments as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wrap Turner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wrap Turner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wrap Turners are responsible for preparing items for shipment by wrapping them securely and efficiently. Their primary objective is to ensure that goods are protected during transportation and storage.

1. Wrapping and Packaging

The most crucial responsibility of a Wrap Turner is to wrap and package products using various materials such as plastic wrap, bubble wrap, and cardboard.

- Select appropriate wrapping materials based on the size, shape, and fragility of the items.

- Wrap items securely to prevent damage during transit.

- Ensure that all items are properly cushioned and protected.

2. Labeling and Marking

Wrap Turners are also responsible for labeling and marking packages with the necessary information.

- Attach shipping labels with accurate recipient and sender information.

- Mark packages with fragile or perishable labels as required.

- Ensure that all labels are clearly visible and securely attached.

3. Inventory Management

Wrap Turners may be involved in inventory management tasks.

- Maintain accurate records of wrapped and packaged items.

- Monitor inventory levels and report any discrepancies or shortages.

- Assist in organizing and labeling storage areas.

4. Workplace Safety and Ergonomics

Wrap Turners must adhere to workplace safety regulations and follow ergonomic principles.

- Use proper lifting techniques to prevent injuries.

- Maintain a clean and organized work area.

- Report any safety hazards or concerns.

Interview Tips

Preparing thoroughly for an interview is essential to ace the Wrap Turner position.

1. Research the Company and Role

Take the time to learn about the company’s products, services, industry, and position requirements. This will demonstrate your interest and enthusiasm.

- Visit the company’s website and social media pages.

- Review the job description carefully and note the key responsibilities.

- Identify any specific skills or experience the company is seeking.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to showcase your relevant skills and experience. Emphasize your abilities in wrapping, packaging, labeling, and inventory management.

- Provide specific examples of your work experience and how it relates to the job requirements.

- Quantify your results whenever possible to demonstrate your impact.

- Be prepared to discuss your proficiency in using different wrapping materials and techniques.

3. Be Enthusiastic and Professional

During the interview, show your enthusiasm for the job and the company. Maintain a professional demeanor and dress appropriately.

- Greet the interviewer with a firm handshake and introduce yourself with confidence.

- Be polite and respectful to everyone you encounter.

- Ask thoughtful questions at the end of the interview to demonstrate your interest and engagement.

4. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the interview.

- Examples of common interview questions include:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “How would you handle a customer who is not satisfied with the wrapping or packaging?”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wrap Turner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.