Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wreath Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

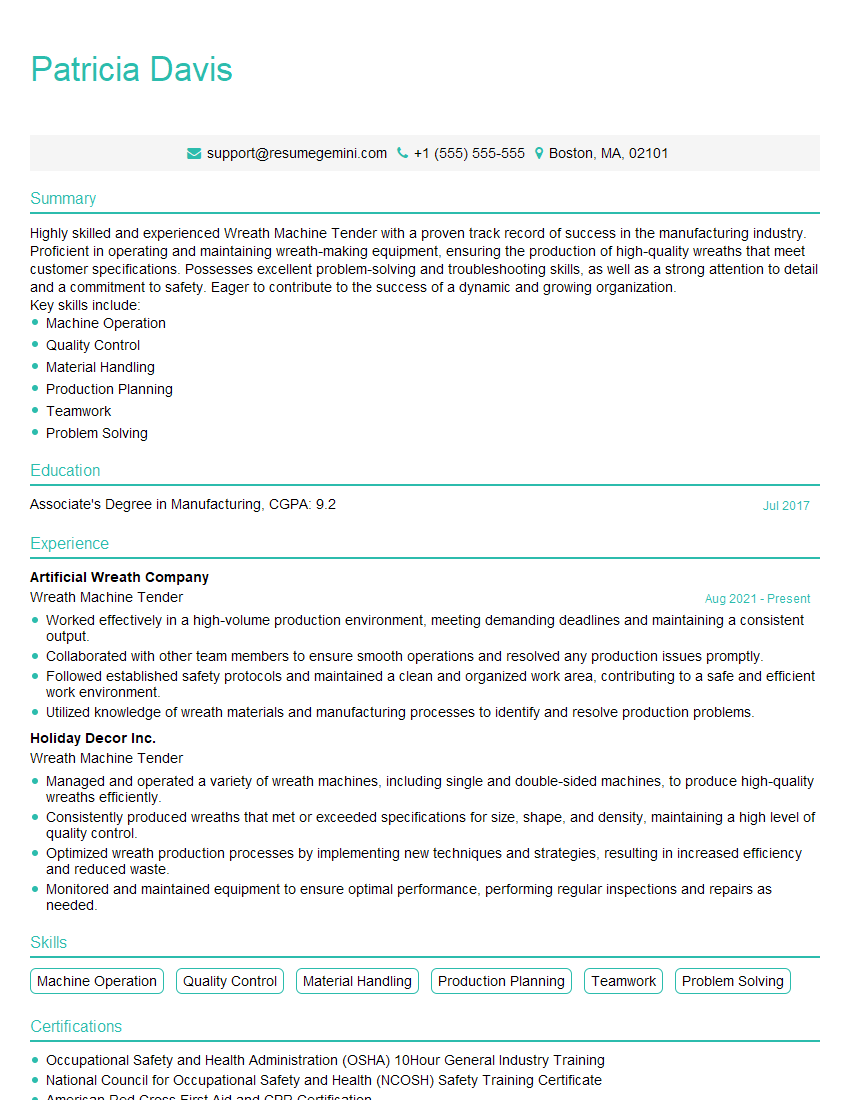

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wreath Machine Tender

1. Explain the steps involved in setting up a wreath machine?

The steps involved in setting up a wreath machine include:

- Inspecting the machine for any damage or wear and tear.

- Cleaning the machine thoroughly using the recommended cleaning solution.

- Installing the wire or other material to be used for the wreath.

- Adjusting the machine settings, such as the wire tension and speed.

- Inspecting the wreath machine to ensure it is functioning properly before using it.

2. How do you troubleshoot common problems with a wreath machine?

Troubleshooting common problems with a wreath machine involves the following steps:

Identifying the problem

- Observing any error messages or indicators on the machine.

- Inspecting the machine for any obvious issues, such as loose wires or damaged components.

- Checking the user manual or consulting with a technician for guidance.

Finding the solution

- Following the troubleshooting steps provided in the user manual or by the technician.

- Replacing any damaged or worn components as necessary.

- Resetting the machine or adjusting the settings to correct the issue.

3. How do you maintain a wreath machine to ensure optimal performance?

To maintain a wreath machine for optimal performance, the following steps are taken:

- Cleaning the machine regularly to remove any dirt or debris.

- Inspecting the machine for any signs of wear or damage.

- Lubricating the moving parts of the machine as recommended in the user manual.

- Calibrating the machine to ensure accurate measurements and production.

- Storing the machine properly when not in use to prevent damage.

4. What are the safety precautions that must be followed when operating a wreath machine?

Safety precautions that must be followed when operating a wreath machine include:

- Wearing appropriate safety gear, such as gloves and safety glasses.

- Keeping hands and loose clothing away from moving parts.

- Not operating the machine while under the influence of alcohol or drugs.

- Following the manufacturer’s instructions for safe operation.

- Being aware of the surroundings and potential hazards.

5. How do you calculate the amount of wire needed to make a wreath of a specific size?

To calculate the amount of wire needed for a wreath of a specific size, the following steps are taken:

- Measuring the circumference of the wreath form.

- Multiplying the circumference by the number of layers of wire desired.

- Adding additional wire for wrapping the ends and securing the wreath.

- Rounding up the total to the nearest whole number to ensure sufficient wire.

6. What types of wire can be used in a wreath machine and what are their advantages and disadvantages?

Various types of wire can be used in a wreath machine, each with its own advantages and disadvantages:

Paper-covered wire:

- Advantages: Affordable, flexible, easy to work with.

- Disadvantages: Can tear or fray, not suitable for outdoor use.

Floral wire:

- Advantages: Strong, flexible, available in various colors.

- Disadvantages: Can be more expensive than paper-covered wire.

Aluminum wire:

- Advantages: Lightweight, strong, weather-resistant.

- Disadvantages: Can be difficult to bend, sharp edges.

Copper wire:

- Advantages: Durable, conductive, easy to solder.

- Disadvantages: More expensive than other types of wire.

7. How do you adjust the tension of the wire on a wreath machine?

Adjusting the tension of the wire on a wreath machine involves the following steps:

- Locating the tension adjustment knob or lever on the machine.

- Turning the knob or lever to increase or decrease the tension.

- Testing the tension by pulling on the wire and observing the resistance.

- Adjusting the tension until it is appropriate for the type of wire and the desired outcome.

8. What are the different types of wreaths that can be made on a wreath machine?

The different types of wreaths that can be made on a wreath machine include:

- Traditional round wreaths

- Oval wreaths

- Heart-shaped wreaths

- Star-shaped wreaths

- Custom-shaped wreaths

9. How do you prepare the materials for making a wreath on a wreath machine?

Preparing materials for making a wreath on a wreath machine involves the following steps:

- Selecting the appropriate type and color of wire.

- Measuring and cutting the wire to the desired length.

- Attaching any decorations or embellishments to the wire, if desired.

- Ensuring that the materials are clean and free of debris.

10. How do you troubleshoot common problems that may occur while operating a wreath machine?

To troubleshoot common problems that may occur while operating a wreath machine, the following steps can be taken:

Identifying the problem

- Observing any error messages or indicators on the machine.

- Inspecting the machine for any obvious issues, such as loose wires or damaged components.

- Checking the user manual or consulting with a technician for guidance.

Finding the solution

- Following the troubleshooting steps provided in the user manual or by the technician.

- Replacing any damaged or worn components as necessary.

- Resetting the machine or adjusting the settings to correct the issue.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wreath Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wreath Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wreath Machine Tender is responsible for operating and maintaining wreath making machines. They ensure that the machines are running smoothly and producing high-quality wreaths. Some of the key responsibilities of a Wreath Machine Tender include:

1. Operating Wreath Making Machines

Wreath Machine Tenders are responsible for operating wreath making machines. They must be able to set up the machines, load the materials, and operate the machines safely and efficiently.

- Set up and adjust wreath making machines according to specifications.

- Load materials, such as greenery, ribbon, and wire, into the machines.

- Operate the machines to create wreaths of various sizes and styles.

- Monitor the machines during operation to ensure that they are running smoothly and producing high-quality wreaths.

2. Maintaining Wreath Making Machines

Wreath Machine Tenders are also responsible for maintaining wreath making machines. They must be able to troubleshoot problems, make repairs, and perform routine maintenance.

- Inspect machines regularly to identify potential problems.

- Troubleshoot and repair machines when they break down.

- Perform routine maintenance, such as cleaning and lubricating machines.

- Keep a record of all maintenance performed on the machines.

3. Quality Control

Wreath Machine Tenders are responsible for ensuring that wreaths meet quality standards. They must be able to inspect wreaths for defects and make sure that they are up to customer specifications.

- Inspect wreaths for defects, such as uneven spacing, loose wire, or damaged greenery.

- Reject wreaths that do not meet quality standards.

- Make adjustments to the machines or materials to improve the quality of the wreaths.

- Provide feedback to management on quality issues.

4. Safety

Wreath Machine Tenders must be aware of the safety hazards associated with operating wreath making machines. They must be able to follow safety procedures and wear appropriate safety gear.

- Follow all safety procedures and wear appropriate safety gear.

- Keep the work area clean and free of debris.

- Report any safety hazards to management.

- Participate in safety training and drills.

Interview Tips

To ace an interview for a Wreath Machine Tender position, it is important to prepare in advance. Here are some tips:

1. Research the Company

Before the interview, take some time to research the company. This will help you understand the company’s culture, values, and products. You can find information about the company on their website, social media pages, and news articles.

- Visit the company’s website to learn about their products, services, and culture.

- Follow the company on social media to see what they are up to and what their employees are saying about them.

- Read news articles about the company to learn about their recent accomplishments and challenges.

2. Practice Answering Interview Questions

One of the best ways to prepare for an interview is to practice answering interview questions. There are many common interview questions that you can expect to be asked, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with wreath making machines?

- How do you handle working under pressure?

3. Dress Professionally

The way you dress for an interview can make a big impression on the interviewer. Make sure to dress professionally, even if the company has a casual dress code.

- Wear clean, pressed clothes that are appropriate for the office environment.

- Avoid wearing clothing that is too revealing or casual.

- Make sure your shoes are clean and polished.

4. Be on Time

Punctuality is important for any job interview. Make sure to arrive on time for your interview, even if you have to leave early to get there.

- Plan your route in advance and allow extra time for traffic or unexpected delays.

- If you are running late, call the interviewer to let them know.

- Don’t be afraid to ask for directions if you get lost.

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you and see if you are a good fit for the position. Don’t try to be someone you’re not.

- Be honest and authentic in your answers.

- Show the interviewer your personality and enthusiasm.

- Don’t be afraid to ask questions about the position or the company.

Next Step:

Now that you’re armed with the knowledge of Wreath Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wreath Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini