Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wrencher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wrencher so you can tailor your answers to impress potential employers.

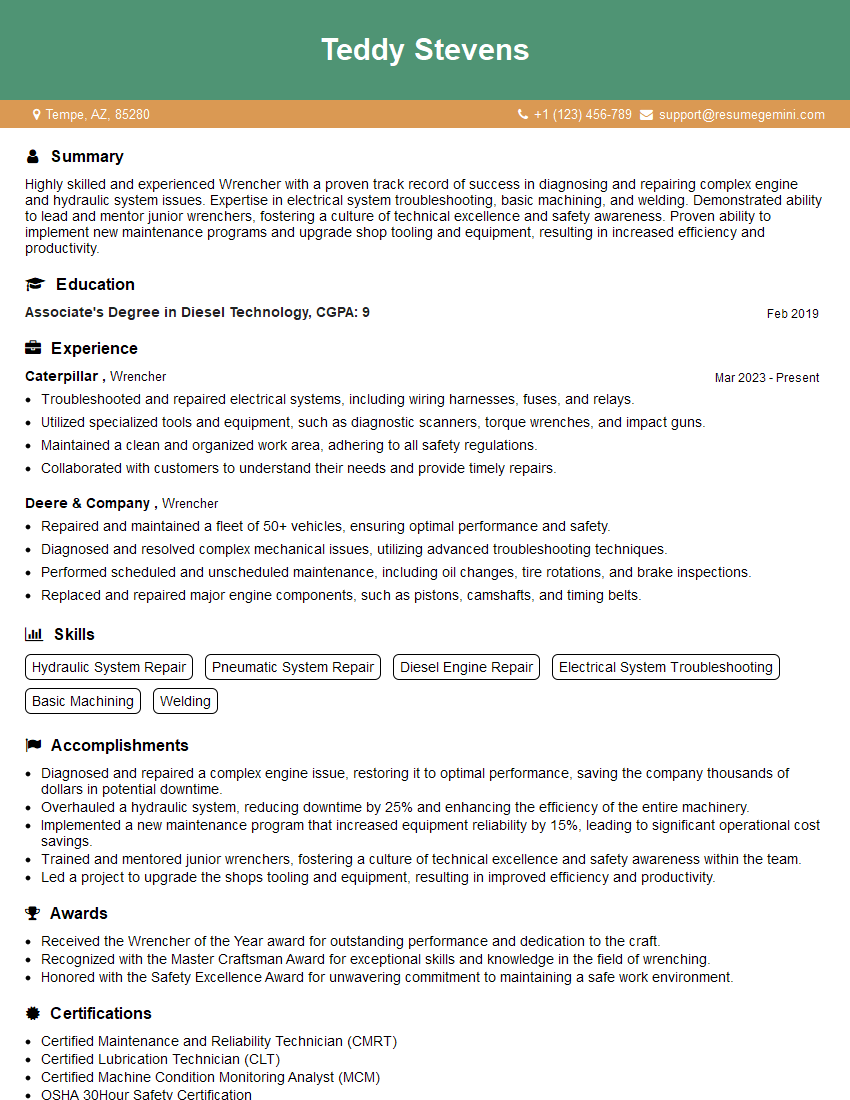

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wrencher

1. Name the five most popular engine oil additives and describe their functions?

- Detergents: Prevent sludge and varnish formation by neutralizing acids and dispersing contaminants.

- Dispersants: Keep contaminants suspended in oil, preventing sludge and deposits.

- Anti-wear: Reduce friction and wear on engine components, minimizing metal-to-metal contact.

- Antioxidants: Protect oil from oxidation and degradation, extending its service life.

- Friction modifiers: Reduce friction between moving parts, improving fuel economy and power output.

2. Explain the purpose and operation of a catalytic converter

Oxygen Reduction

- Converts nitrogen oxides (NOx) to nitrogen (N2) and oxygen (O2).

- Uses a platinum-rhodium catalyst.

Carbon Monoxide Oxidation

- Converts carbon monoxide (CO) to carbon dioxide (CO2).

- Uses a palladium catalyst.

Hydrocarbon Oxidation

- Converts unburned hydrocarbons (HC) to CO2 and water (H2O).

- Uses a combination of platinum and palladium catalysts.

3. Describe the different types of spark plugs and their applications?

- Copper: Good heat transfer, economical, suitable for standard ignition systems.

- Platinum: Longer lifespan (60,000-100,000 miles), reduced fouling.

- Iridium: Even longer lifespan (100,000+ miles), improved fuel efficiency, high performance engines.

- Double Platinum/Iridium: Extended lifespan, enhanced spark durability.

4. Explain the operation and importance of a fuel injector?

A fuel injector is an electro-mechanical device responsible for delivering a precisely metered amount of fuel into the engine’s combustion chamber during the appropriate injection cycle.

- Uses a solenoid or piezoelectric crystal to open and close a valve.

- Controls fuel flow by modulating the injection pulse width.

- Ensures optimal fuel-air mixture, enhancing combustion efficiency and reducing emissions.

5. Describe the purpose and types of engine sensors?

- Oxygen sensor: Monitors exhaust oxygen levels to adjust air-fuel ratio.

- Mass airflow sensor: Measures the mass of incoming air for fuel injection control.

- Throttle position sensor: Indicates throttle valve position to the ECU for fuel delivery.

- Coolant temperature sensor: Monitors engine coolant temperature for ECU adjustments.

- Knock sensor: Detects engine knock and adjusts ignition timing to prevent damage.

6. Explain the process of engine valve timing?

Valve timing refers to the precise coordination of opening and closing the intake and exhaust valves in an engine.

- Intake valve timing: Controls the timing of air and fuel intake.

- Exhaust valve timing: Controls the timing of exhaust gas release.

- Valve overlap: A period where both intake and exhaust valves are open, facilitating gas exchange.

- Optimizing valve timing improves engine performance, efficiency, and emissions.

7. Describe the different types of engine bearings?

- Plain bearings: Consist of a metal back and a soft lining (e.g., tin, lead, bronze).

- Rolling element bearings: Utilize balls or rollers to reduce friction and wear.

- Hydrodynamic bearings: Use a thin film of oil to separate the bearing surfaces.

- Hydrostatic bearings: Use pressurized oil to create a more stable oil film.

8. Explain the purpose and working principle of a turbocharger?

A turbocharger is a device that uses exhaust gas energy to compress incoming air, increasing engine power and efficiency.

- Consists of a turbine and a compressor.

- Exhaust gases drive the turbine, which in turn spins the compressor.

- The compressor compresses incoming air, increasing its density.

- Higher density air results in more efficient combustion and increased power output.

9. Describe the function and operation of a viscous coupling in a 4WD system?

A viscous coupling is a mechanical device that transmits torque between two shafts while allowing for some slippage under different operating conditions.

- Consists of two sets of clutch plates, one connected to each shaft.

- When one shaft rotates faster than the other, a viscous fluid between the plates generates torque.

- The amount of torque transmitted depends on the difference in shaft speeds and the fluid’s viscosity.

- Provides smooth engagement and torque transfer in 4WD systems.

10. Explain the principles and components of a hydraulic brake system?

- Pascal’s Law: Pressure applied to a confined fluid is transmitted equally throughout the system.

- Master cylinder: Generates hydraulic pressure when the brake pedal is depressed.

- Brake lines: Transmit the hydraulic pressure to the wheels.

- Brake calipers/wheel cylinders: Convert hydraulic pressure into mechanical force to actuate the brake pads.

- Brake pads: Apply friction to the brake rotors or drums to slow down the vehicle.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wrencher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wrencher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Wrencher, you will play a crucial role in maintaining and repairing vehicles. Your responsibilities will include diagnosing mechanical issues, performing repairs, and ensuring that vehicles meet safety and performance standards.

1. Troubleshooting and Diagnostics

Analyze vehicle systems and components to identify mechanical issues. Conduct diagnostic tests and inspections to pinpoint the root cause of problems.

- Use diagnostic equipment to assess engine performance, electrical systems, and hydraulics.

- Inspect vehicles for leaks, corrosion, and loose connections.

2. Vehicle Repair and Maintenance

Perform repairs and replacements of faulty parts and components. Follow manufacturer’s guidelines and industry best practices to ensure accurate and efficient repairs.

- Replace engines, transmissions, brakes, and other major components.

- Repair electrical systems, hydraulic lines, and suspension systems.

3. Vehicle Maintenance

Inspect and maintain vehicles to prevent breakdowns and extend their lifespan. Perform scheduled maintenance tasks such as oil changes, tire rotations, and fluid level checks.

- Inspect brakes, filters, and belts for wear and tear.

- Recommend preventive maintenance measures to customers.

4. Safety and Compliance

Adhere to safety protocols and ensure that vehicles meet industry standards and regulations. Inspect vehicles for compliance with safety features.

- Follow OSHA and EPA guidelines for handling hazardous materials.

- Ensure vehicles comply with fuel efficiency and emissions standards.

Interview Tips

To ace your Wrencher interview, follow these effective preparation tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and services. Understand the challenges and trends in the automotive industry.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Practice Your Answers

Prepare answers to common interview questions related to your skills, experience, and work style. Practice delivering concise and tailored responses.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight quantifiable achievements and demonstrate your problem-solving abilities.

3. Showcase Your Technical Knowledge

Emphasize your mechanical understanding and technical skills. Describe how you diagnose and repair vehicles efficiently.

- mention specific diagnostic tools and techniques you are proficient in.

- Share examples of complex repairs you have successfully completed.

4. Highlight Your Safety and Compliance Expertise

Demonstrate your awareness of safety protocols and compliance regulations. Explain your adherence to OSHA and EPA guidelines.

- Provide examples of how you ensure vehicles meet safety standards.

- Highlight your knowledge of emission control systems and fuel efficiency measures.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wrencher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.