Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wringer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wringer so you can tailor your answers to impress potential employers.

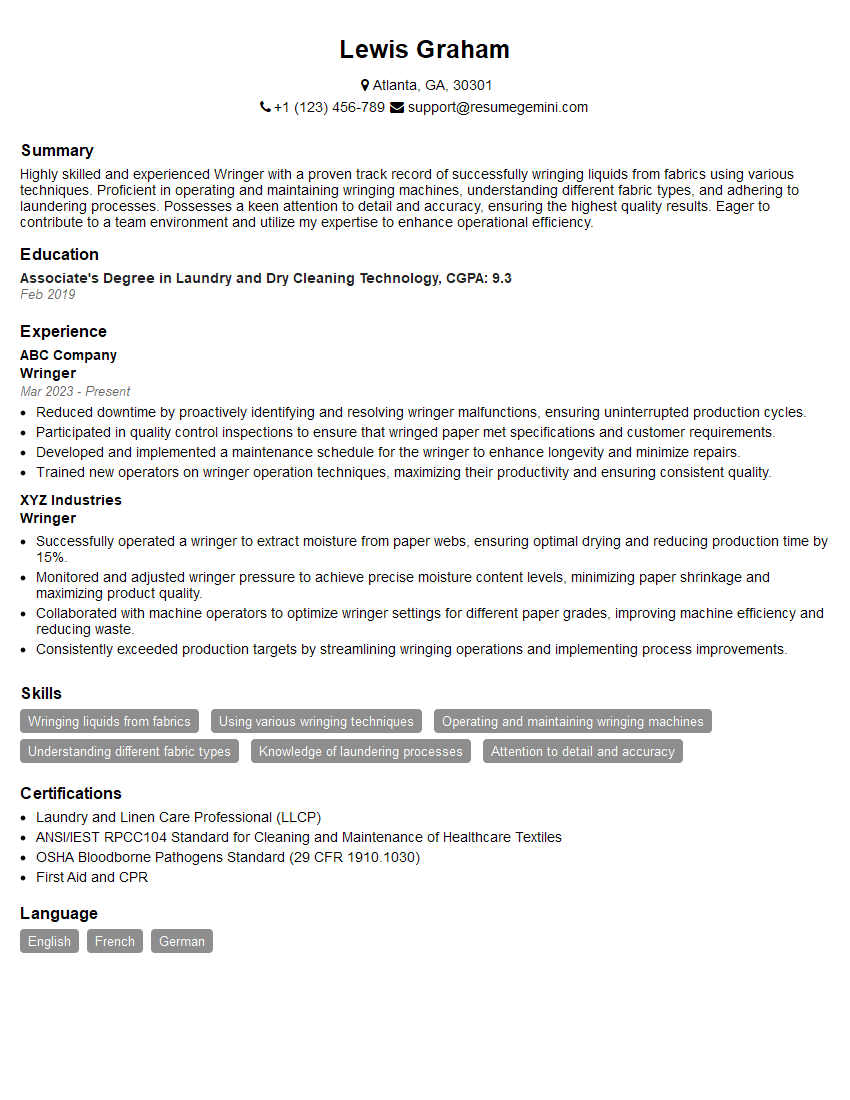

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wringer

1. Explain the concept of wringing in the context of textiles?

- Wringing is a mechanical process used to remove excess water from textiles after washing.

- It involves passing the wet textile through a series of rollers that apply pressure to squeeze out the water.

- The amount of pressure applied and the speed of the rollers determine the effectiveness of the wringing process.

2. What are the different types of wringers used in the textile industry?

Types of Wringers

- Roller wringers: Consist of two or more rollers that rotate in opposite directions and apply pressure to the textile.

- Centrifugal wringers: Utilize centrifugal force to remove water by spinning the textile at high speeds.

- Pneumatic wringers: Employ compressed air to apply pressure to the textile, ensuring gentle handling of delicate fabrics.

3. How do you determine the optimal wringing pressure for different types of textiles?

- The optimal pressure depends on the fabric type, weight, and moisture content.

- Delicate fabrics require lower pressure to avoid damage, while heavier fabrics can withstand higher pressure.

- Testing and experience are crucial to determine the appropriate pressure for each fabric type.

4. What are the key factors to consider when designing a wringing system?

- Fabric type: Different fabrics have varying wringing requirements.

- Wringing capacity: The system must handle the desired volume of textiles.

- Energy efficiency: Minimizing energy consumption is important.

- Space constraints: The system must fit within the available space.

- Maintenance: The system should be easy to maintain and repair.

5. Describe the safety precautions to be observed when operating a wringing machine?

- Wear appropriate safety gear, including gloves and safety glasses.

- Ensure that the machine is properly grounded to prevent electrical hazards.

- Do not place hands or fingers near the wringing rollers.

- Keep the work area clean and free of obstructions.

- Follow the manufacturer’s operating instructions carefully.

6. How do you troubleshoot common problems encountered during wringing?

- Insufficient wringing: Check roller pressure, speed, and fabric type.

- Excessive fabric damage: Reduce roller pressure or change wringing method.

- Machine vibration: Check for unbalanced loads, misalignment, or worn parts.

- Electrical problems: Contact a qualified electrician for repairs.

7. What are the latest advancements in wringing technology?

- Automated pressure control: Sensors measure fabric thickness and adjust pressure accordingly.

- Variable speed drives: Optimize wringing efficiency and fabric handling.

- Touchless wringing: Ultrasonic or electromagnetic technologies remove water without direct contact.

- Eco-friendly wringing systems: Reduce water and energy consumption.

8. Describe your experience with wringing machine maintenance and repair.

I have extensive experience in maintaining and repairing various types of wringing machines. My responsibilities include regular inspections, lubrication, and replacement of worn parts. I am proficient in troubleshooting and resolving common issues, ensuring optimal machine performance and minimizing downtime.

9. How do you stay updated with the latest technological advancements in the textile industry?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Collaborate with industry experts and researchers.

- Engage in online learning and webinars.

10. How do you manage multiple projects and tasks simultaneously?

- Prioritize tasks based on importance and urgency.

- Create a structured schedule and stick to it.

- Delegate responsibilities and collaborate with colleagues.

- Utilize time management tools and techniques.

- Regularly evaluate progress and make adjustments as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wringer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wringer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wringers play a crucial role in maintaining the cleanliness and hygiene of commercial and industrial establishments. Their primary responsibilities include operating and maintaining wringing machines to extract excess water from textiles, ensuring the efficient and hygienic processing of fabrics.

1. Machine Operation and Maintenance

Wringers are responsible for the safe and efficient operation of wringing machines. This involves:

- Preparing the machine for use, ensuring all safety measures are in place.

- Loading and unloading textiles into and from the machine, ensuring proper alignment and balance.

- Monitoring machine functions, including water flow, temperature, and extraction pressure.

- Performing routine maintenance tasks, such as cleaning and lubricating the machine, to ensure optimal performance.

2. Textile Handling and Inspection

Wringers handle a wide variety of textiles, including linens, towels, and garments. Their responsibilities include:

- Sorting and classifying textiles according to type, size, and condition.

- Inspecting textiles for any damage or defects before and after wringing.

- Identifying and isolating soiled or damaged textiles for appropriate treatment.

- Maintaining proper storage conditions for textiles to prevent contamination and damage.

3. Safety and Hygiene Compliance

Wringers are responsible for maintaining a safe and hygienic work environment. This involves:

- Adhering to all safety protocols and regulations related to machine operation and textile handling.

- Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Maintaining a clean and organized workspace, including proper disposal of waste materials.

- Following established hygiene standards to prevent the spread of germs and bacteria.

4. Quality Control

Wringers play a crucial role in ensuring the quality of processed textiles. Their responsibilities include:

- Monitoring the extraction process to ensure textiles are properly wrung and meet the desired moisture content.

- Performing visual inspections to ensure textiles are free from damage or defects.

- Providing feedback on the wringing process to identify areas for improvement.

- Maintaining records of processed textiles for quality control purposes.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of making a positive impression and landing the job. Here are some key tips to help you ace your Wringer interview:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific role you are applying for. This will give you a good understanding of the company’s culture, values, and the responsibilities associated with the position.

- Visit the company’s website to learn about their mission, products, services, and industry reputation.

- Read online reviews and articles about the company to gain insights into its work environment and employee satisfaction.

- Carefully review the job description and make note of the key requirements and responsibilities.

2. Practice Common Interview Questions

Many interview questions are common across different industries and roles. By practicing these questions in advance, you can become more comfortable and confident in your responses.

- Prepare answers to questions about your skills, experience, and qualifications.

- Practice describing your strengths and weaknesses and how they relate to the role.

- Anticipate questions about your motivation for applying to the position and why you are interested in working for the company.

3. Prepare Industry-Specific Questions

In addition to common interview questions, you should also prepare for questions that are specific to the Wringer industry. This demonstrates your knowledge and interest in the field.

- Research industry trends and developments to show that you are up-to-date with the latest practices.

- Be prepared to discuss your understanding of different types of wringing machines and their applications.

- If possible, seek out articles or case studies that demonstrate your knowledge and expertise in the field.

4. Showcase Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the job requirements. Use specific examples to demonstrate your abilities.

- Highlight your experience in operating and maintaining wringing machines.

- Provide examples of how you have ensured the quality of processed textiles.

- Share your knowledge of safety and hygiene protocols in a work environment.

5. Ask Meaningful Questions

At the end of the interview, take the opportunity to ask thoughtful questions that demonstrate your interest and engagement. This is a chance to show that you are genuinely interested in the position and the company.

- Ask about the company’s growth plans and future goals.

- Inquire about the training and development opportunities available to employees.

- Ask about the company’s commitment to sustainability and environmental responsibility.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wringer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.