Are you gearing up for an interview for a Yarn Dyer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Yarn Dyer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

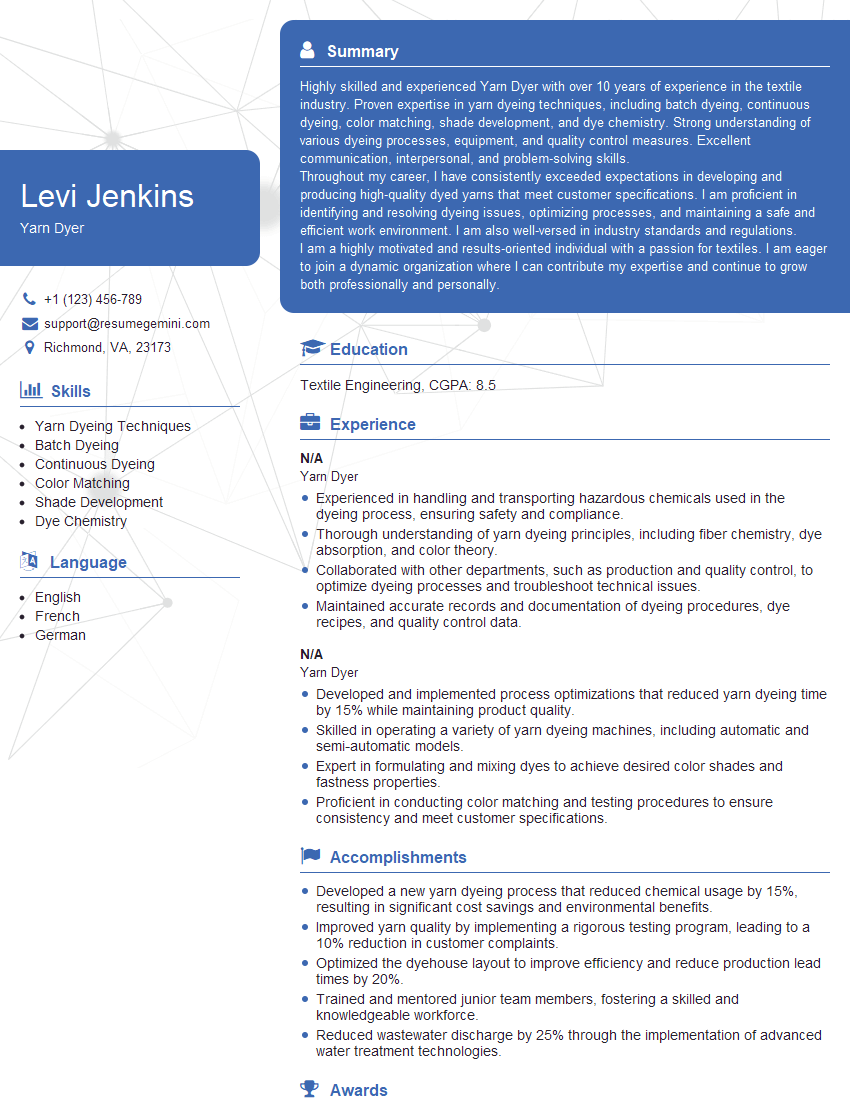

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yarn Dyer

1. Explain the process of dyeing cotton yarn using reactive dyes?

The process of dyeing cotton yarn using reactive dyes involves several steps to achieve optimal color uptake and fastness:

- Preparation: The yarn is scoured to remove impurities and then bleached to enhance dye uptake.

- Dyeing: The yarn is immersed in a dye bath containing reactive dyes, electrolytes (e.g., salt), and alkali (e.g., soda ash). The temperature and pH are controlled to optimize dye absorption.

- Fixation: After dyeing, the yarn is treated with a fixing agent (e.g., sodium acetate) to form covalent bonds between the dye and the cellulose fibers, ensuring colorfastness.

- Washing and drying: The dyed yarn is thoroughly washed to remove excess dye and chemicals, then dried to restore its handle and regain its original weight.

2. What are the key factors that affect the shade of the dyed yarn?

Choice of dye:

- Different dyes have unique chemical structures that produce specific colors.

- The concentration of the dye in the bath influences the intensity of the shade.

Dyeing conditions:

- Temperature and pH affect dye absorption and color development.

- Time and agitation ensure uniform dye penetration.

Yarn properties:

- Fiber type (e.g., cotton, polyester) influences dye affinity and shade.

- Yarn construction (e.g., count, twist) affects dye penetration and evenness.

3. How do you control colorfastness in dyed yarn?

- Selection of dyes: Choose dyes with good wash, light, and rubbing fastness properties.

- Optimizing dyeing conditions: Control temperature, pH, and dye concentration to ensure proper dye fixation.

- Post-dyeing treatments: Apply fixing agents, softeners, and anti-pilling agents to enhance color retention and fabric handle.

- Quality control: Conduct regular fastness tests to ensure dyed yarn meets industry standards.

4. Describe the different types of dyeing machines used in yarn dyeing?

- Hank dyeing machines: Used for dyeing yarn in skein form, allowing for even dye penetration and good color uniformity.

- Package dyeing machines: Suitable for dyeing yarn wound onto cones or packages, providing high efficiency and productivity.

- Jet dyeing machines: Employ high-pressure jets to circulate dye liquor through the yarn, resulting in faster dyeing cycles and better color penetration.

- Pad dyeing machines: Used for continuous dyeing of open-width yarn, where the yarn passes through a dye bath and is squeezed to remove excess dye.

5. How do you troubleshoot common dyeing problems, such as uneven dyeing or color bleeding?

- Uneven dyeing: Check for proper dye dispersion, temperature control, and agitation. Adjust dyeing parameters accordingly.

- Color bleeding: Identify the cause (e.g., poor dye fixation, excessive agitation). Optimize dyeing conditions, use fixing agents, or blend dyes with different fastness properties.

- Barré: Caused by uneven yarn tension or dyeing conditions. Adjust machine settings, control tension, and ensure uniform dye penetration.

6. What is the role of auxiliaries in yarn dyeing?

- Wetting agents: Improve dye penetration by reducing surface tension of water.

- Leveling agents: Promote uniform dye distribution throughout the yarn.

- Retarders: Slow down dye absorption to prevent uneven dyeing.

- Fixing agents: Form covalent bonds between dyes and fibers, ensuring colorfastness.

- Softeners: Enhance the feel and handle of dyed yarn.

7. How do you ensure the accuracy and consistency of dye recipes?

To ensure accuracy and consistency:

- Use accurate weighing scales and measuring equipment.

- Follow established recipes and procedures.

- Maintain proper storage conditions for dyes and chemicals.

- Regularly calibrate dyeing machines and equipment.

- Conduct color matching and shade verification before bulk dyeing.

8. What are the environmental considerations in yarn dyeing?

- Wastewater treatment: Implement effective effluent treatment systems to minimize water pollution.

- Dye selection: Choose eco-friendly dyes that have low environmental impact.

- Energy efficiency: Optimize dyeing processes to reduce energy consumption.

- Chemical management: Adhere to safety protocols and minimize chemical usage.

9. How do you stay updated with the latest advances in yarn dyeing technology?

- Attend industry conferences and workshops.

- Read technical journals and industry publications.

- Engage with suppliers and manufacturers for product updates.

- Explore online resources and forums.

10. What quality control measures do you implement to ensure the quality of dyed yarn?

- Color matching: Compare dyed yarn to approved standards.

- Fastness testing: Conduct wash, light, and rubbing fastness tests.

- Yarn strength testing: Ensure that dyeing does not compromise yarn strength.

- Visual inspection: Check for uneven dyeing, contamination, and other defects.

- Regular monitoring: Track key dyeing parameters and make adjustments as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yarn Dyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yarn Dyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Yarn Dyeing is a process that involves coloring and dyeing of yarns using various techniques and materials. The Yarn Dyer is responsible for carrying out this process efficiently to ensure the production of high-quality dyed yarns that meet customer specifications.

1. Yarn Preparation and Dyeing

Preparing yarns for dyeing, including scouring, bleaching, and mercerizing to enhance dye receptivity and improve yarn quality.

- Selecting appropriate dyes and chemicals for specific yarn types and desired color.

- Operating dyeing machines, such as beck dyeing machines, jet dyeing machines, and package dyeing machines, to apply dyes to yarns.

2. Color Matching and Quality Control

Matching colors accurately according to customer specifications using spectrophotometers and other color measurement devices.

- Performing quality control tests to ensure dyed yarns meet the desired color, shade, and fastness requirements.

- Maintaining color standards and records to ensure consistency and traceability.

3. Process Optimization and Troubleshooting

Optimizing dyeing processes to improve efficiency, reduce costs, and maintain product quality.

- Identifying and resolving technical issues related to dyeing processes, equipment, and materials.

- Implementing process improvements and new technologies to enhance productivity and quality.

4. Environmental Compliance and Safety

Ensuring compliance with environmental regulations related to wastewater treatment, disposal of chemicals, and air emissions.

- Following safety protocols and handling chemicals and equipment responsibly.

- Participating in environmental management programs to minimize the impact of dyeing processes on the environment.

Interview Tips

Preparing thoroughly for a Yarn Dyer interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Before the interview, it is crucial to research the company you are applying to and the specific Yarn Dyer position you are interested in. Understand the company’s products, services, industry reputation, and its commitment to quality and sustainability.

- Visit the company’s website and social media pages to gather information.

- Review industry news and articles to demonstrate your knowledge of the textile dyeing sector.

2. Highlight Your Technical Skills and Experience

During the interview, emphasize your technical skills and experience in yarn dyeing. Showcase your proficiency in different dyeing techniques, color matching, quality control, and process optimization.

- Quantify your accomplishments and provide specific examples of projects or initiatives where you made a meaningful contribution.

- Discuss your knowledge of various dyes, chemicals, and dyeing equipment.

3. Demonstrate Your Problem-Solving Abilities

Yarn dyeing often involves troubleshooting and problem-solving. Highlight your analytical skills and ability to identify and resolve technical issues. Share examples of how you have successfully identified and resolved dyeing-related challenges.

- Describe situations where you identified the root cause of a dyeing problem and implemented a solution that improved the process.

- Discuss your approach to continuous improvement and process optimization.

4. Emphasize Your Attention to Detail and Quality Assurance

Yarn dyeing requires meticulous attention to detail and a commitment to quality assurance. Stress your ability to follow instructions precisely, maintain accurate records, and ensure that dyed yarns meet the desired specifications.

- Highlight your experience in using color measurement devices and performing quality control tests.

- Discuss your understanding of industry standards and regulations related to yarn dyeing.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare a few well-researched questions that show your enthusiasm for the role and your alignment with the company’s goals.

- Inquire about the company’s future plans for sustainability and environmental protection.

- Ask about opportunities for professional development and growth within the organization.

Next Step:

Now that you’re armed with the knowledge of Yarn Dyer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Yarn Dyer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini