Are you gearing up for an interview for a Yarn Handler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Yarn Handler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

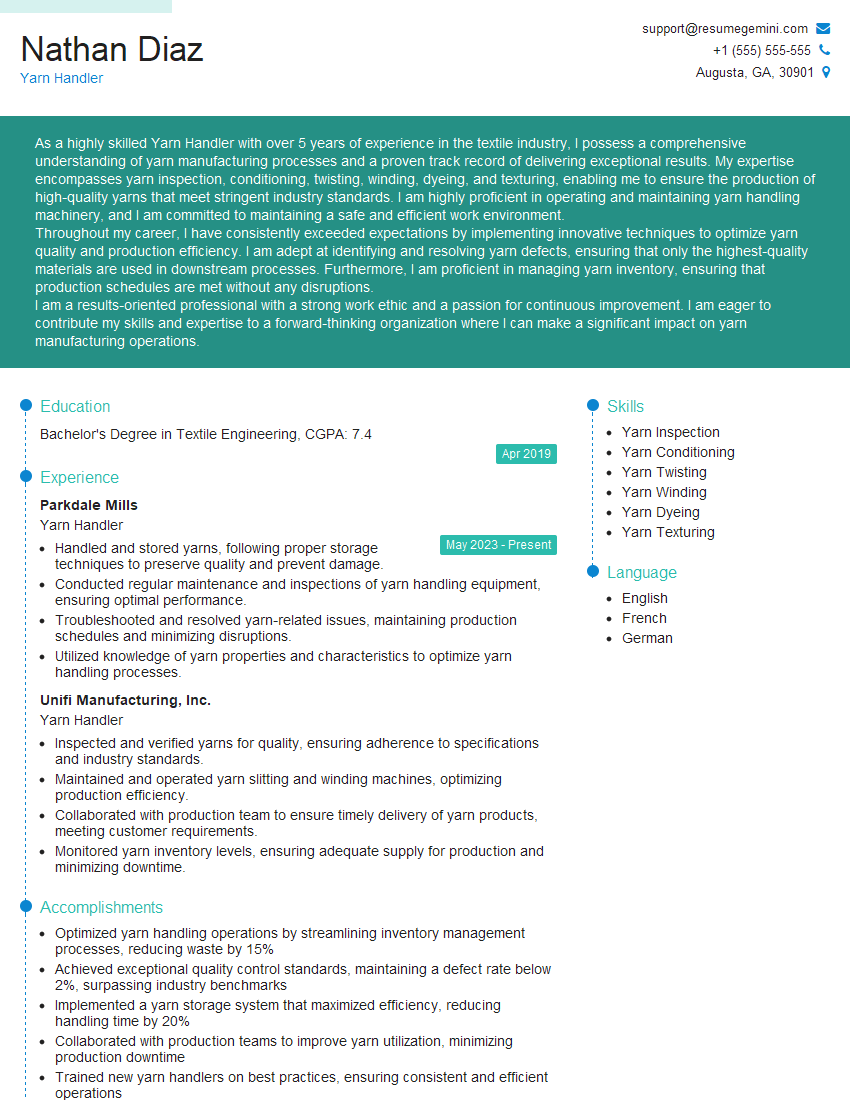

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yarn Handler

1. Explain the process of yarn handling in a textile mill.

The yarn handling process in a textile mill involves several steps to ensure smooth production.

- Yarn Unloading: Receiving and unloading yarn from suppliers, ensuring proper storage and handling.

- Yarn Storage: Storing yarn in designated areas under controlled conditions to maintain quality and prevent damage.

- Yarn Inspection: Inspecting yarn for defects, count, twist, and other quality parameters to meet production standards.

- Yarn Conditioning: Preparing yarn for further processing by conditioning it to achieve optimum moisture content and regain.

- Yarn Dispensing: Issuing yarn to different production departments based on production orders and requirements.

- Yarn Waste Management: Handling and disposing of yarn waste generated during processing to maintain a clean and efficient work environment.

2. What are the different types of yarn handling equipment used in the industry?

Yarn Unloading Equipment

- Forklifts

- Overhead cranes

Yarn Storage Equipment

- Yarn racks

- Yarn trolleys

Yarn Inspection Equipment

- Yarn inspection machines

- Yarn testing equipment

Yarn Conditioning Equipment

- Yarn conditioning machines

- Humidification systems

Yarn Dispensing Equipment

- Yarn creels

- Yarn feeders

3. Describe the importance of maintaining proper yarn tension during handling.

Maintaining proper yarn tension is crucial for several reasons:

- Yarn Quality: Excessive tension can damage yarn fibers, reducing strength and causing breaks.

- Production Efficiency: Uneven tension can lead to yarn tangling, machine stoppages, and reduced productivity.

- Fabric Quality: Yarn tension affects fabric properties such as smoothness, texture, and appearance.

- Equipment Protection: High tension can strain yarn handling equipment, leading to premature wear and tear.

4. How do you ensure the accuracy of yarn count and twist?

Ensuring yarn count and twist accuracy is critical for meeting production specifications:

- Regular Calibration: Calibrating yarn testing equipment regularly to ensure accurate measurements.

- Yarn Sampling: Taking representative yarn samples from different batches for testing.

- Statistical Analysis: Using statistical methods to analyze test results and identify variations or deviations.

- Supplier Verification: Verifying yarn count and twist specifications with suppliers to ensure consistency.

5. What are the common yarn defects you encounter during handling and how do you address them?

- Yarn Breakage: Inspect yarn for weak spots, adjust tension settings, and handle yarn carefully.

- Yarn Tangling: Use yarn guides and tensioners, and train staff on proper handling techniques.

- Yarn Contamination: Store yarn in clean environments, inspect for foreign objects, and use proper packaging.

- Yarn Unevenness: Monitor yarn count and twist parameters, and adjust processing conditions as needed.

- Yarn Slubs: Identify the source of slubs (e.g., fiber impurities, machine settings), and implement corrective measures.

6. How do you manage yarn inventory to prevent shortages and excess stock?

Effective yarn inventory management involves several strategies:

- Demand Forecasting: Predicting future yarn requirements based on production plans and historical data.

- Safety Stock: Maintaining a buffer stock to cover unexpected fluctuations in demand.

- Just-in-Time Inventory: Ordering yarn only when needed to minimize storage and carrying costs.

- Inventory Tracking: Using inventory management systems to track yarn stock levels and monitor usage.

- Supplier Coordination: Collaborating with suppliers to ensure timely deliveries and avoid stockouts.

7. How do you handle customer complaints related to yarn quality?

Addressing customer complaints requires a professional and efficient approach:

- Investigation: Investigate the complaint thoroughly to identify the root cause.

- Communication: Communicate promptly with the customer to acknowledge the complaint and provide updates.

- Resolution: Develop a solution to address the customer’s concerns, such as yarn replacement or compensation.

- Preventive Measures: Implement measures to prevent similar complaints from occurring in the future.

- Documentation: Keep accurate records of customer complaints and resolutions for future reference and analysis.

8. What are the safety precautions you follow while handling yarn?

- Wear appropriate PPE: Gloves, safety glasses, and protective clothing.

- Use proper lifting techniques: Avoid overexertion and use mechanical aids when necessary.

- Maintain a clean work environment: Keep yarn storage areas free from tripping hazards and obstructions.

- Follow machine safety guidelines: Operate yarn handling equipment according to manufacturers’ instructions.

- Report hazards: Immediately report any unsafe conditions or equipment malfunctions.

9. How do you stay updated on the latest trends and advancements in yarn handling technology?

Staying updated is essential for continuous improvement:

- Attend industry conferences and exhibitions: Network with experts and learn about new technologies.

- Read industry publications and journals: Keep abreast of advancements in yarn handling practices.

- Seek training opportunities: Participate in workshops and training programs to enhance skills.

- Collaborate with equipment manufacturers: Stay informed about new developments and potential benefits.

- Embrace digital tools: Utilize software and apps for inventory management, quality control, and process optimization.

10. Describe a situation where you had to handle a challenging yarn handling issue and how you resolved it.

In a previous role, we encountered an issue with excessive yarn breakage during winding. After investigating, we identified that the yarn had uneven tension. We adjusted the tension settings on the winding machine and implemented a stricter yarn inspection process to identify weak spots. As a result, we significantly reduced yarn breakage and improved production efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yarn Handler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yarn Handler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Yarn Handler is responsible for various aspects related to the handling and maintenance of yarn in a production facility. Their key responsibilities include:

1. Yarn Handling and Storage

Preparing and handling yarn for production, including unwinding, winding, and loading yarn onto machinery.

- Inspecting yarn for defects and ensuring its quality meets production standards.

- Storing yarn in designated areas, maintaining proper inventory, and adhering to storage guidelines.

2. Machine Operation and Maintenance

Operating and monitoring yarn-handling machinery, such as winding machines, warping machines, and creels.

- Performing regular maintenance tasks, including cleaning and lubrication, to ensure optimal machine performance.

- Identifying and troubleshooting machine malfunctions, taking corrective actions to minimize downtime.

3. Process Control and Quality Assurance

Monitoring the yarn handling process and ensuring adherence to production standards.

- Inspecting yarn at various stages of production to identify defects and maintain quality.

- Collaborating with quality control personnel to implement corrective measures and improve production efficiency.

4. Safety and Compliance

Following established safety protocols and procedures to ensure a safe working environment.

- Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses, while handling yarn.

- Maintaining a clean and organized work area, reducing tripping hazards and other potential safety risks.

Interview Tips

To prepare for a Yarn Handler interview, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, culture, and the specific requirements of the Yarn Handler position.

- Visit the company’s website, LinkedIn page, and Glassdoor reviews to gather information.

- Identify the key responsibilities and skills highlighted in the job description, and align your qualifications accordingly.

2. Practice Answering Common Interview Questions

Anticipate questions related to your experience in yarn handling, machine operation, and quality control.

- Prepare examples that demonstrate your abilities and highlight your strengths.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers clearly and effectively.

3. Showcase Your Technical Skills

Emphasize your proficiency in operating yarn-handling machinery and your understanding of yarn handling processes.

- Highlight your experience in identifying and resolving yarn defects.

- Discuss your knowledge of yarn types, yarn counts, and yarn quality standards.

4. Highlight Your Safety Consciousness

Demonstrate your commitment to maintaining a safe work environment.

- Explain your understanding of safety protocols and your experience in following them.

- Share examples of how you have proactively identified and mitigated safety hazards.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Yarn Handler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Yarn Handler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.