Are you gearing up for an interview for a Yarn Mercerizer Operator Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Yarn Mercerizer Operator Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

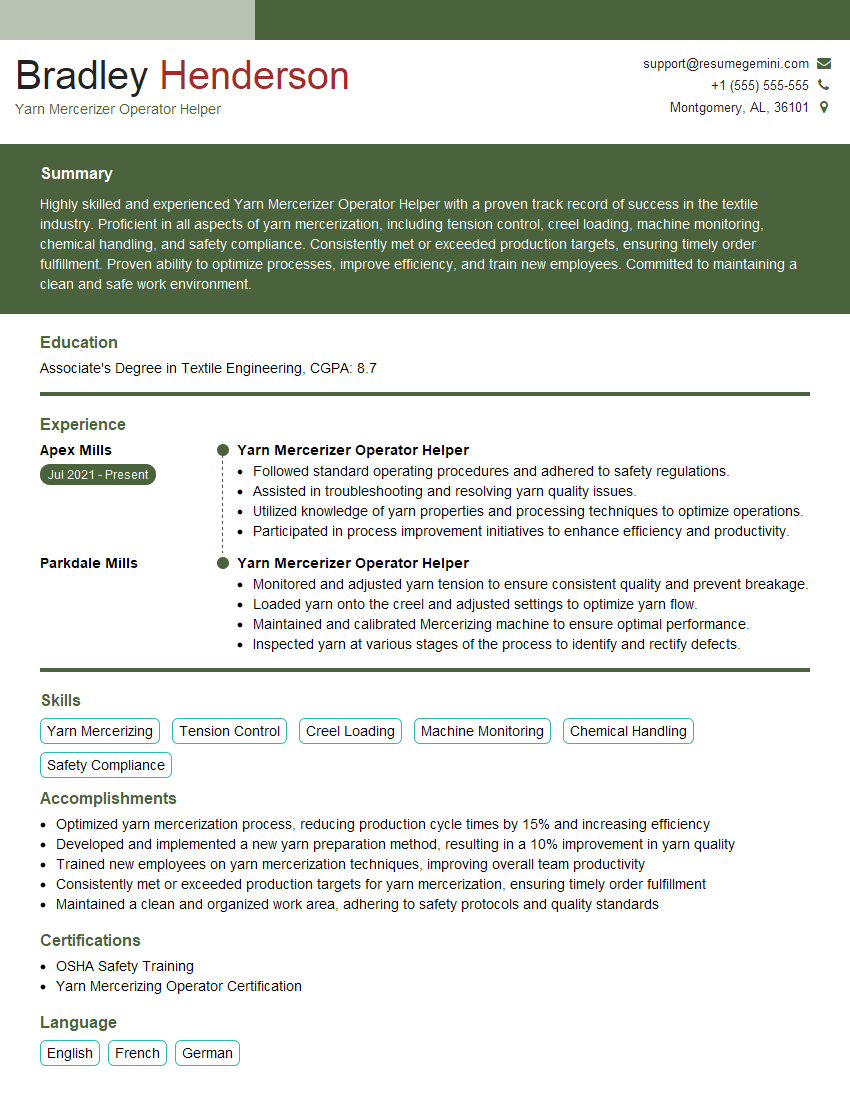

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yarn Mercerizer Operator Helper

1. Explain the mercerization process?

Mercerization is a treatment process applied to cotton yarn to enhance its strength, luster, and dye affinity. The process involves subjecting the yarn to a concentrated solution of sodium hydroxide (NaOH) under tension, followed by a washing and neutralization step.

- Improves the strength of the yarn by up to 25%.

- Enhances the luster of the yarn, giving it a silky appearance.

- Increases the dye affinity of the yarn, allowing it to absorb and retain dyes more effectively.

2. What are the key factors to consider when operating a yarn mercerizing machine?

Tension Control:

- Maintaining the correct yarn tension is crucial to prevent breakage.

- Tension should be adjusted based on the yarn type and count.

Chemical Concentration:

- The concentration of sodium hydroxide solution must be monitored regularly.

- Variations in concentration can affect the mercerization quality.

Temperature Control:

- The temperature of the mercerizing solution should be maintained within a specific range.

- Higher temperatures can damage the yarn, while lower temperatures may result in insufficient mercerization.

3. Describe the safety precautions to be observed while working with sodium hydroxide?

- Wear appropriate protective gear, including gloves, goggles, and a chemical apron.

- Handle sodium hydroxide solution with care, as it can cause skin burns and eye irritation.

- Dispose of waste solution and contaminated materials properly according to established protocols.

- Be aware of the potential for spills and leaks and have emergency response procedures in place.

- Follow all established safety guidelines and training provided by the employer.

4. Explain the role of auxiliary chemicals in the mercerization process?

- Surfactants: Promote wetting and penetration of the yarn by the mercerizing solution.

- Stabilizers: Prevent the decomposition of sodium hydroxide and extend its effectiveness.

- Anti-creasing agents: Reduce the tendency of the yarn to develop creases during the mercerization process.

- Optical brighteners: Enhance the whiteness and brightness of the yarn.

5. What troubleshooting steps would you take if the mercerized yarn is not meeting the desired quality standards?

- Check the tension settings of the machine and adjust if necessary.

- Verify the concentration of the sodium hydroxide solution and adjust if required.

- Monitor the temperature of the mercerizing bath and ensure it is within the specified range.

- Inspect the yarn for any visible defects or abnormalities.

- Review the chemical composition of the mercerizing solution to identify any potential imbalances.

6. Describe the quality control procedures involved in yarn mercerizing?

- Visual inspection of the yarn for any defects or unevenness.

- Tensile strength testing to assess the yarn’s strength.

- Luster measurement to evaluate the yarn’s shine and appearance.

- Dye affinity testing to determine the yarn’s ability to absorb and retain dyes.

- Monitoring of the mercerizing solution’s concentration and temperature to ensure optimal conditions.

7. How do you ensure the efficient operation of the yarn mercerizing machine?

- Regular maintenance and cleaning of the machine to prevent malfunctions.

- Monitoring the performance of the machine and identifying any potential issues early.

- Adhering to established operating procedures and guidelines to optimize machine efficiency.

- Communicating any operational challenges or downtime to the supervisor promptly.

8. What is your understanding of the environmental impact of yarn mercerizing and how can it be minimized?

Yarn mercerizing involves the use of sodium hydroxide, which can be harmful to the environment if not disposed of properly. To minimize the environmental impact, the following measures can be taken:

- Neutralizing the spent mercerizing solution before disposal to reduce its alkalinity.

- Recycling or reusing the mercerizing solution whenever possible.

- Implementing water conservation practices to reduce water consumption during the mercerizing process.

- Following proper waste management procedures to prevent contamination of soil and water bodies.

9. What are your career aspirations and how do you see this role as a stepping stone in achieving them?

In the long term, I aspire to advance my career in the textile industry and eventually assume a leadership role in production or quality management. I believe that this role as a Yarn Mercerizer Operator Helper will provide me with a solid foundation and valuable experience.

- It will allow me to gain hands-on knowledge of the mercerizing process and develop a deep understanding of the technical aspects involved.

- I am eager to contribute to the team’s success and take on additional responsibilities as I grow in my abilities.

- I am confident that the skills and knowledge acquired in this role will serve as a stepping stone towards my ultimate career aspirations.

10. Do you have any questions for me about the role or the company?

I would be grateful if you could provide more insights into the company’s sustainability initiatives and its commitment to environmental responsibility.

- I am also curious about the opportunities for professional development and training that are available to employees.

- Additionally, I would like to know more about the company’s culture and values, as I believe that a positive and supportive work environment is essential for success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yarn Mercerizer Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yarn Mercerizer Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Yarn Mercerizer Operator Helper assists in the operation and maintenance of yarn mercerizing machines, which are used to treat yarn to improve its strength, luster, and dye affinity. Key responsibilities include:

1. Machine Operation

Assist in setting up, operating, and monitoring yarn mercerizing machines.

- Load and unload yarn onto machines.

- Adjust machine settings to ensure proper yarn treatment.

- Monitor machine performance and identify any potential issues.

2. Yarn Handling

Handle yarn with care to prevent tangles and breakage.

- Inspect yarn before and after mercerization for defects.

- Store yarn in proper conditions to maintain its quality.

- Follow safety protocols for handling yarn and chemicals.

3. Maintenance and Troubleshooting

Assist in maintaining and troubleshooting yarn mercerizing machines.

- Clean and lubricate machines as per maintenance schedules.

- Identify and resolve minor machine issues.

- Report any major issues to the operator.

4. Quality Control

Assist in ensuring the quality of yarn after mercerization.

- Perform visual inspections and tests to verify yarn properties.

- Record and maintain quality control data.

- Follow established quality standards and procedures.

Interview Tips

To ace the interview for a Yarn Mercerizer Operator Helper position, it’s crucial to be well-prepared and highlight your relevant skills and experience. Here are some tips:

1. Research the Company and Role

Before the interview, thoroughly research the company’s background, industry, and products. Understand the specific responsibilities of the Yarn Mercerizer Operator Helper role and how it aligns with your skills.

- Visit the company website and social media pages to gather information.

- Read industry publications and articles to gain insights into the company’s market position.

- Prepare questions to ask the interviewer about the company and the role during the interview.

2. Highlight Relevant Experience

Emphasize your previous experience in yarn processing or related fields. Showcase your knowledge of yarn properties, mercerization processes, and quality control measures. Quantify your accomplishments whenever possible to demonstrate your impact.

- Use keywords from the job description in your resume and interview answers.

- Provide specific examples of how you have improved yarn quality, reduced machine downtime, or implemented safety protocols.

- Be prepared to discuss your understanding of the principles of yarn mercerization and its impact on yarn properties.

3. Demonstrate Problem-Solving Abilities

Hiring managers often seek individuals who can identify and resolve problems effectively. Highlight your troubleshooting skills and ability to work independently. Share examples of how you have diagnosed and fixed machine issues or identified process inefficiencies.

- Describe a time when you identified a problem with a mercerizing machine and took steps to resolve it.

- Explain how you have analyzed yarn quality data to identify areas for improvement.

- Discuss your approach to handling unexpected situations and making quick decisions.

4. Emphasize Safety and Attention to Detail

Yarn mercerization involves handling chemicals and operating heavy machinery. Emphasize your safety consciousness and attention to detail. Highlight any certifications or training you have received in safety protocols.

- Describe your understanding of the safety procedures for yarn mercerization.

- Share examples of how you have maintained a clean and organized work area.

- Explain your approach to following instructions and adhering to quality standards.

5. Practice and Prepare

Practice answering common interview questions and prepare questions to ask the interviewer. This will help you feel confident and prepared during the interview. Consider conducting a mock interview with a friend or family member to get feedback.

- Research common interview questions for yarn processing positions.

- Prepare thoughtful questions to ask the interviewer about the company, the role, and the team.

- Dress professionally and arrive on time for the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Yarn Mercerizer Operator Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.