Are you gearing up for an interview for a Yarn Preparation Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Yarn Preparation Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

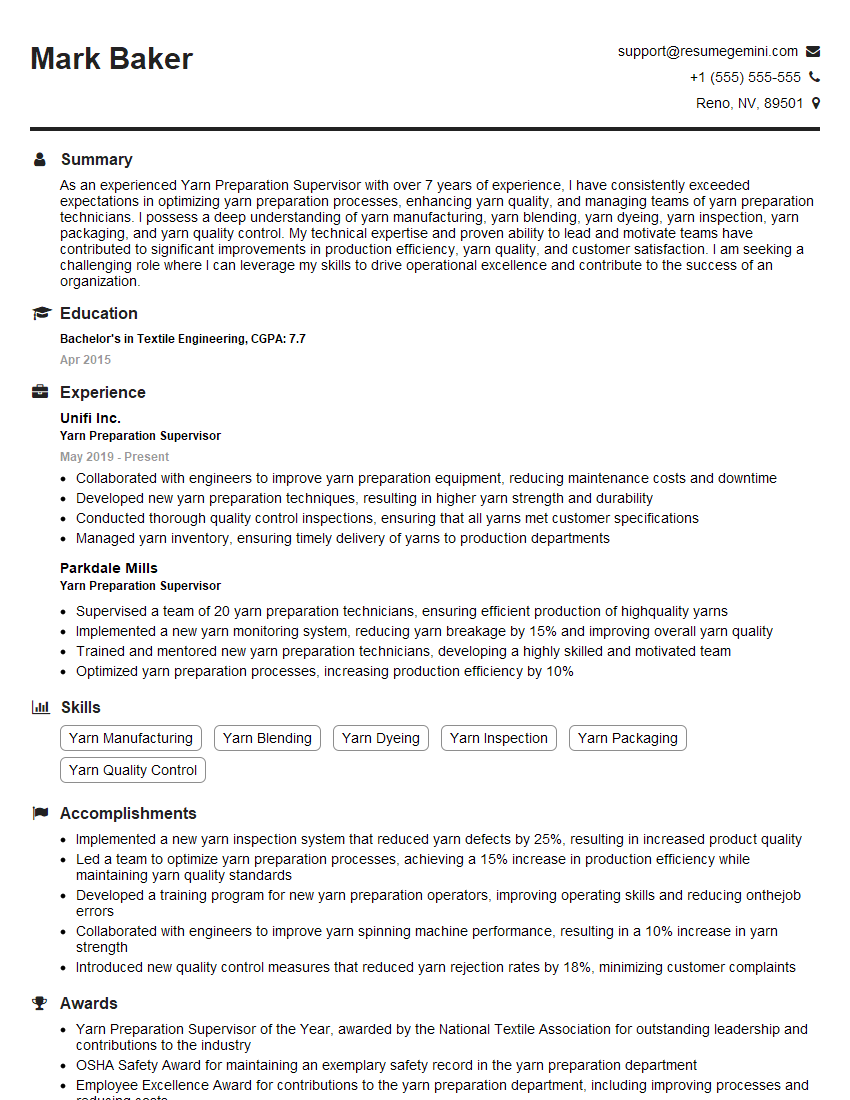

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yarn Preparation Supervisor

1. Explain the different spinning systems used in yarn preparation and their applications?

- Ring Spinning: Used to produce fine, high-quality yarns for various applications, such as clothing, bedding, and medical textiles.

- Open-End Spinning: A continuous process that produces coarser yarns suitable for knitting, weaving, and nonwovens.

- Vortex Spinning: Produces unique yarns with low hairiness and improved bulk for specialty applications.

2. Describe the key factors influencing yarn quality during preparation?

Raw Material Properties

- Fiber length

- Fiber strength

- Fiber fineness

Process Parameters

- Drafting

- Twisting

- Drawing

Equipment Condition

- Machine settings

- Maintenance and calibration

3. How do you ensure consistent yarn quality throughout the preparation process?

- Establish and adhere to strict process specifications.

- Monitor process parameters (e.g., draft, twist) continuously.

- Perform regular equipment inspections and maintenance.

- Implement statistical process control (SPC) techniques.

- Conduct yarn testing at various stages to identify and correct deviations.

4. What troubleshooting techniques do you employ when yarn defects occur during preparation?

- Identify the type and location of the defect.

- Trace back the process to find the root cause.

- Adjust machine settings, raw materials, or process conditions accordingly.

- Consult with technical experts or suppliers for support.

- Document and communicate solutions to prevent future occurrences.

5. How do you optimize productivity and minimize yarn waste during preparation?

- Maximize machine utilization by scheduling efficient production runs.

- Reduce downtime for maintenance and changeovers.

- Minimize fiber loss during drafting and spinning.

- Implement waste reduction techniques, such as yarn splicing.

- Train operators on best practices for efficient yarn handling.

6. Describe the role of automation in modern yarn preparation facilities?

- Reduced manual labor and increased efficiency.

- Improved yarn quality consistency through precise process control.

- Real-time data collection and analysis for quality monitoring.

- Integrated systems for optimized production planning and scheduling.

7. How do you maintain a safe and clean work environment in the yarn preparation area?

- Enforce safety protocols and provide personal protective equipment.

- Maintain good housekeeping practices to prevent tripping hazards.

- Control dust and fiber accumulation to minimize respiratory issues.

- Train employees on proper handling and disposal of chemicals.

- Conduct regular safety audits and inspections.

8. Explain the importance of employee training and development in yarn preparation?

- Improves job performance and productivity.

- Ensures adherence to process standards and safety protocols.

- Enhances troubleshooting capabilities.

- Prepares employees for advancement opportunities.

- Fosters a culture of continuous improvement.

9. How do you measure and evaluate the performance of your yarn preparation team?

- Yarn quality metrics (e.g., strength, count, twist).

- Production output and efficiency.

- Waste reduction and cost savings.

- Employee safety and well-being.

- Customer satisfaction and feedback.

10. Describe your experience in implementing lean manufacturing principles in yarn preparation?

- Value stream mapping to identify waste and inefficiencies.

- Process standardization and optimization.

- Just-in-time inventory management.

- Continuous improvement initiatives (e.g., Kaizen events).

- Employee involvement and empowerment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yarn Preparation Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yarn Preparation Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Yarn Preparation Supervisor is responsible for overseeing and managing the production of yarn in a textile mill, ensuring that the yarn meets the specified quality standards and production targets.

1. Production Management

Oversee the production process, including planning, scheduling, and monitoring yarn production to meet customer orders and production targets.

- Allocate resources, including personnel, machinery, and materials to optimize production efficiency.

- Monitor production progress and make necessary adjustments to ensure timely completion of orders.

2. Quality Control

Implement and maintain quality control standards throughout the yarn preparation process to ensure the production of high-quality yarn.

- Conduct regular inspections of raw materials, machinery, and finished products to identify and address any potential quality issues.

- Collaborate with quality assurance team to develop and implement quality control measures, such as testing procedures and inspection checkpoints.

3. Equipment Maintenance

Supervise the maintenance and repair of yarn preparation equipment to ensure optimal performance and prevent breakdowns.

- Develop and implement preventive maintenance plans to minimize downtime and extend equipment life.

- Monitor equipment performance and identify potential issues, coordinating repairs and maintenance with technical teams.

4. Team Management

Lead and supervise a team of yarn preparation operators, providing guidance, training, and support to ensure efficient and productive operations.

- Establish clear performance expectations and provide regular feedback to team members.

- Identify training and development needs and provide opportunities for skill enhancement.

Interview Tips

Preparing for an interview for a Yarn Preparation Supervisor position requires thorough research and a well-rounded understanding of the role. Here are some tips and hacks to help you ace the interview:

1. Research the Company and the Role

Familiarize yourself with the company’s website, industry news, and recent developments to demonstrate your interest and knowledge of the organization.

- Identify specific aspects of the company’s operations that align with your skills and experience.

- Research the industry trends and technological advancements related to yarn preparation to show your up-to-date knowledge.

2. Practice Your Answers and Showcase Your Experience

Prepare answers to common interview questions that highlight your relevant skills and experience.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your accomplishments.

- Quantify your results whenever possible, using metrics and data to demonstrate the impact of your contributions.

3. Emphasize Quality Control and Production Efficiency

Yarn Preparation Supervisors play a crucial role in ensuring the quality of the final product. Emphasize your understanding of quality control principles and your ability to implement and maintain rigorous standards.

- Highlight your experience in identifying and resolving quality issues, and demonstrate your commitment to meeting or exceeding customer expectations.

- Discuss your strategies for optimizing production efficiency, such as lean manufacturing techniques or process improvements you have implemented.

4. Showcase Your Leadership and Communication Skills

Effective communication and leadership are essential for managing a team. Emphasize your ability to motivate and inspire your team members, and your skills in resolving conflicts and building a positive work environment.

- Provide examples of how you have successfully led and developed teams in the past.

- Describe your communication style and how you adapt it to different situations and audiences.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Yarn Preparation Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!