Are you gearing up for a career in Yarn Winder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Yarn Winder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

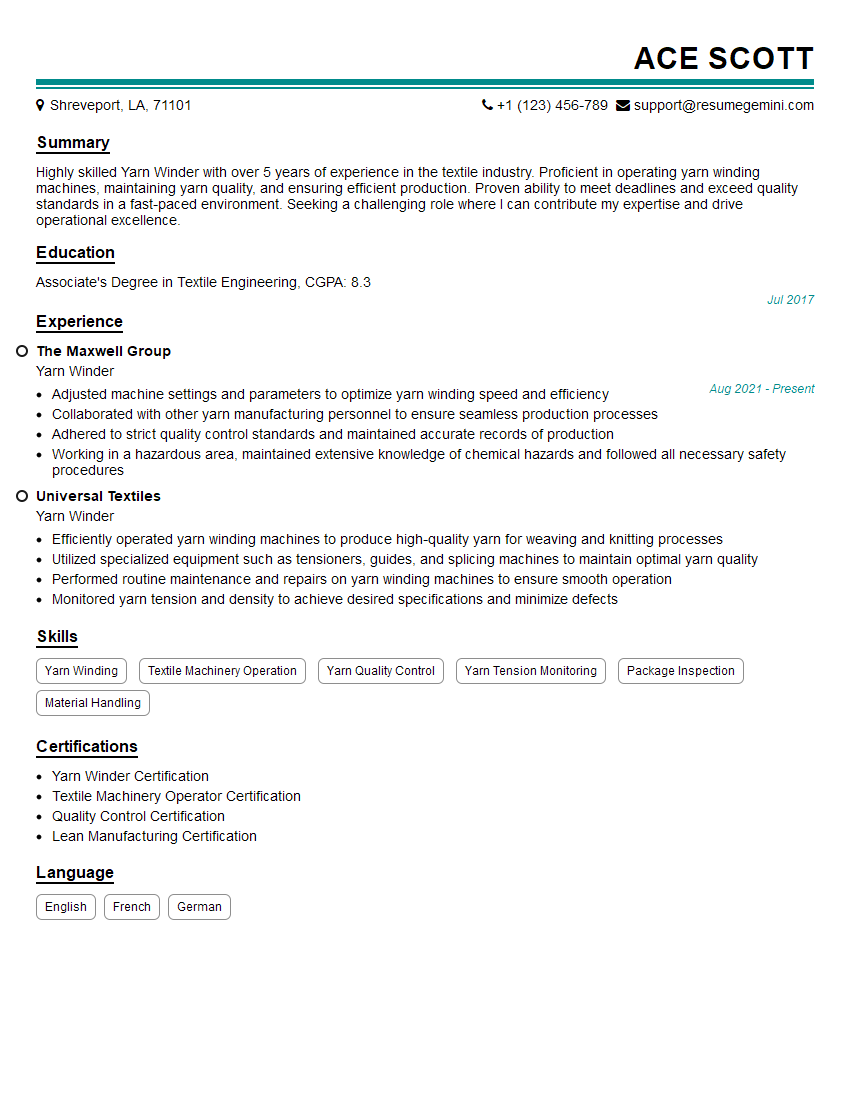

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yarn Winder

1. What are the different types of yarn winding machines?

- Skein winding machine

- Cone winding machine

- Cheese winding machine

- Cross winding machine

2. What are the factors that affect the quality of the wound yarn?

Yarn tension

- Too high tension can cause yarn breakage

- Too low tension can result in loose winding

Winding speed

- Too high speed can cause yarn entanglement

- Too low speed can reduce productivity

3. How do you adjust the tension of the yarn during winding?

The tension of the yarn can be adjusted by changing the pressure of the yarn guide or by using a tension control device.

4. How do you troubleshoot a yarn winding machine?

Some common troubleshooting steps include:

- Checking the yarn tension

- Inspecting the yarn path for obstructions

- Checking the winding speed

- Clearing any yarn breaks

5. What are the different types of yarn packages?

- Skein

- Cone

- Cheese

- Bobbin

6. What are the advantages of using a cone winding machine?

- Higher winding speeds

- Improved yarn quality

- Increased productivity

7. What are the disadvantages of using a skein winding machine?

- Lower winding speeds

- Lower yarn quality

- Reduced productivity

8. What are the safety precautions that must be taken when operating a yarn winding machine?

- Wear appropriate safety clothing and equipment

- Keep the machine area clean and free of debris

- Be aware of the moving parts of the machine

- Never operate the machine when it is not properly guarded

9. What is the importance of proper yarn winding?

Proper yarn winding ensures that the yarn is evenly distributed on the package, which is essential for subsequent processes such as weaving and knitting.

10. What are the qualities of a good yarn winder?

- Attention to detail

- Mechanical aptitude

- Ability to work independently

- Strong work ethic

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yarn Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yarn Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Yarn winders are responsible for operating yarn winding machines to wind yarn into specified packages. They ensure the machines are running smoothly and make necessary adjustments to maintain quality and efficiency. Key responsibilities include:

1. Machine Operation and Maintenance

Operate yarn winding machines to wind yarn onto specified packages, such as cones, tubes, or bobbins.

- Set up and adjust machines according to specifications and requirements.

- Monitor machines during operation to ensure proper functioning and prevent breakdowns.

- Perform routine maintenance tasks, such as cleaning, lubricating, and replacing parts.

- Identify and troubleshoot machine malfunctions and take corrective actions.

2. Yarn Handling and Quality Control

Handle yarn with care to prevent damage and ensure quality.

- Inspect yarn for defects and remove any imperfections.

- Ensure proper tension and winding speed to maintain yarn quality.

- Conduct quality checks on wound packages to meet specifications.

3. Production and Efficiency

Meet production targets and maintain efficiency in winding operations.

- Plan and schedule winding operations to optimize production output.

- Maximize machine utilization and minimize downtime.

- Identify and implement process improvements to enhance productivity.

4. Safety and Compliance

Adhere to safety regulations and company policies to ensure a safe work environment.

- Follow established safety protocols and wear appropriate safety gear.

- Maintain a clean and organized work area.

- Report any accidents, injuries, or hazards promptly.

Interview Tips

Preparing thoroughly for a yarn winder interview can significantly increase your chances of success. Here are some helpful tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and the specific yarn winder position you are applying for. This will help you understand the company’s culture, goals, and the expectations for the role.

2. Practice Common Interview Questions

Anticipate and prepare answers to common interview questions related to your skills, experience, and qualifications. Examples include :

- Tell me about your experience operating yarn winding machines.

- How do you ensure the quality of wound yarn packages?

- Describe a situation where you identified and resolved a machine malfunction.

3. Highlight your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact. For instance, you could mention:

- Increased production output by 15% through efficient machine utilization.

- Reduced downtime by 20% by implementing preventive maintenance measures.

- Maintained zero defects in wound yarn packages for over six months.

4. Emphasize Safety and Compliance

Stress your commitment to safety and compliance in the workplace. Describe your understanding of relevant safety protocols and your adherence to them. Mention any safety certifications or training you have completed.

5. Be Professional and Enthusiastic

During the interview, maintain a professional demeanor and demonstrate your enthusiasm for the position. Dress appropriately, arrive on time, and make eye contact with the interviewer. Ask thoughtful questions to show your interest and engagement.

Next Step:

Now that you’re armed with the knowledge of Yarn Winder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Yarn Winder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini