Are you gearing up for a career in Yarn Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Yarn Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

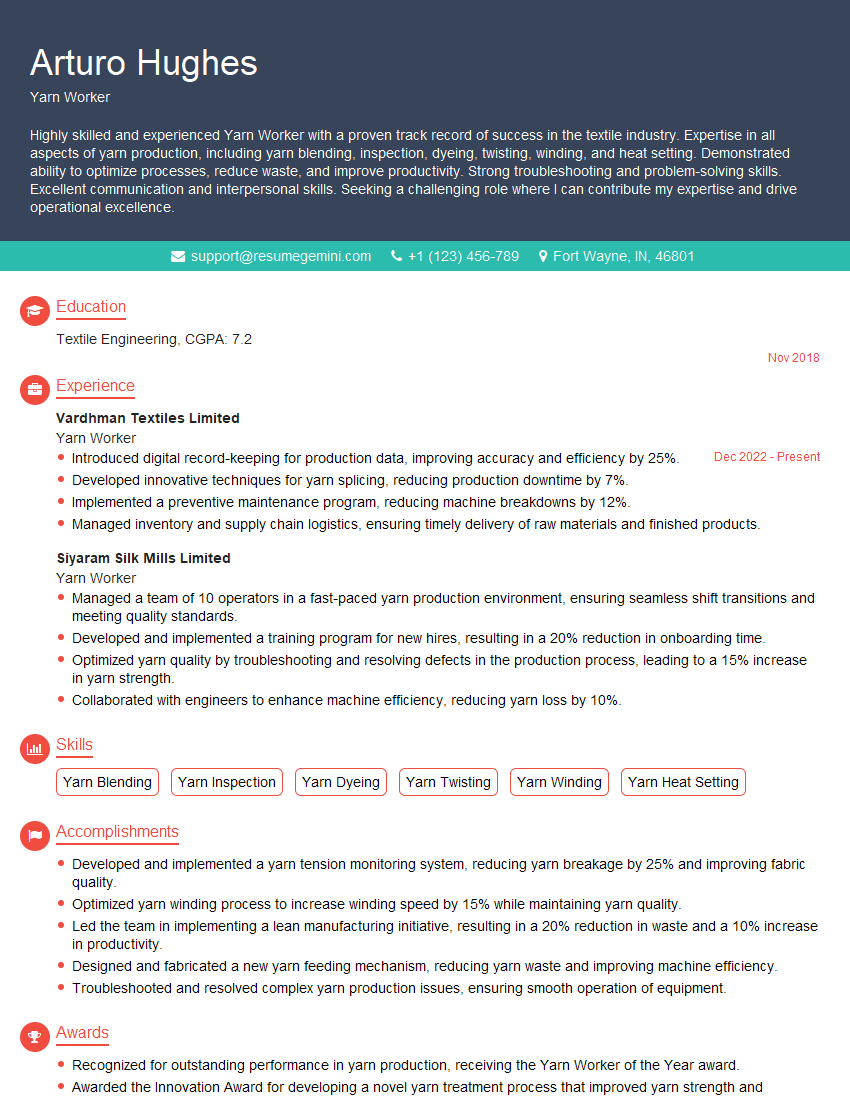

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yarn Worker

1. What are the different types of yarn you work with and how do you determine the appropriate yarn for a particular project?

I have experience working with a wide range of yarn types, including natural fibers like wool, cotton, and silk, as well as synthetic fibers like acrylic, nylon, and polyester. I consider factors such as the project’s purpose, the desired texture and drape, and the budget to determine the most suitable yarn.

2. Describe the process of yarn winding and how you ensure consistent tension and even distribution of the yarn on the bobbin?

Yarn winding involves transferring yarn from hanks or cones onto bobbins. I use a yarn winder machine to achieve consistent tension and even distribution. I calibrate the machine according to the yarn weight and type, and I monitor the tension throughout the process to ensure the yarn is wound evenly onto the bobbin.

3. Explain the different methods of yarn dyeing and the advantages and disadvantages of each?

There are several yarn dyeing methods, including stock dyeing, package dyeing, and skein dyeing. Stock dyeing involves adding dye to raw fiber before it’s spun into yarn. Package dyeing colors yarn that’s already wound onto bobbins, while skein dyeing is used for hanks of yarn. Each method has its advantages and disadvantages in terms of cost, colorfastness, and evenness of dyeing.

4. How do you troubleshoot common yarn problems, such as breakage, uneven tension, or incorrect color matching?

I have encountered various yarn problems and have developed techniques to troubleshoot them. For breakage, I check for sharp edges or obstructions in the yarn path. Uneven tension can be caused by incorrect machine calibration or yarn quality, which I adjust accordingly. Incorrect color matching may occur due to dye lot variations or improper dyeing techniques, which I address by consulting with the dyeing department or adjusting the dyeing process.

5. Describe the different types of yarn spinning processes and the impact they have on the yarn’s properties?

Yarn spinning can be done using ring spinning, open-end spinning, or rotor spinning. Ring spinning produces fine, high-quality yarn with low hairiness. Open-end spinning results in bulkier, more economical yarn. Rotor spinning offers high production rates and is suitable for short-staple fibers.

6. How do you calculate the yarn count and twist factor?

Yarn count is the measure of the yarn’s thickness or fineness, while twist factor refers to the amount of twist in the yarn. I use the formula Yarn Count = (Weight of 1000 meters of yarn)/(Weight of 1 gram of yarn), and Twist Factor = (Number of twists per inch)/(Yarn Count). Understanding these calculations is essential for yarn production and quality control.

7. Explain the process of yarn testing and the different types of tests performed to ensure yarn quality?

Yarn testing is crucial to ensure compliance with specifications. Tests include tensile strength testing to measure yarn’s ability to withstand breaking force, elongation testing to assess its stretchiness, and evenness testing to determine variations in yarn diameter. I use specialized equipment and follow standardized procedures to conduct these tests and analyze the results.

8. How do you manage inventory and ensure the timely availability of yarn for production?

Effective inventory management is vital. I maintain accurate records of yarn stock levels, monitor usage patterns, and coordinate with the production team to anticipate future needs. I implement a “just-in-time” inventory system to minimize waste and optimize yarn availability.

9. Describe your experience in working with different yarn suppliers and how you ensure consistent yarn quality?

I have established relationships with reliable yarn suppliers and conduct thorough evaluations before selecting vendors. I visit their facilities, inspect their production processes, and perform quality checks on yarn samples. By maintaining strong supplier relationships, I ensure a consistent supply of high-quality yarn that meets our specifications.

10. How do you stay updated with the latest trends and advancements in the yarn industry?

I actively participate in industry events, workshops, and online forums to stay abreast of the latest developments in yarn technology, sustainable practices, and new product innovations. I subscribe to trade publications and research papers to expand my knowledge and apply best practices in my work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yarn Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yarn Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Yarn Workers oversee the production of yarn, ensuring its quality and quantity. Their key responsibilities include:1. Yarn Production:

Yarn Workers operate various machines, including spinning frames, twisting machines, and winding machines, to produce yarn.

- Set up and calibrate machinery according to specifications.

- Monitor production process, making adjustments as necessary to optimize yarn quality.

- Troubleshoot and resolve production issues, ensuring efficient yarn production.

2. Quality Control:

Yarn Workers are responsible for ensuring the quality of the produced yarn.

- Inspect yarn for defects and take corrective actions as needed.

- Conduct quality tests to assess yarn properties, such as strength, count, and appearance.

- Maintain records of quality control data for analysis and improvement.

3. Material Handling:

Yarn Workers handle raw materials and finished yarn, ensuring proper storage and inventory.

- Unload and store raw materials, such as fiber and chemicals.

- Maintain and organize yarn inventory, ensuring efficient distribution.

- Operate forklifts or other equipment for material handling.

4. Process Optimization:

Yarn Workers actively participate in improving production efficiency and quality.

- Identify areas for improvement and suggest process modifications.

- Collaborate with other team members to develop and implement process optimization strategies.

- Monitor and analyze production data to make informed decisions for process optimization.

Interview Tips and Hacks

Preparation is key to acing an interview. Here are some tips and tricks to help Yarn Worker candidates make a strong impression:1. Research the Company and Industry:

Candidates should thoroughly research the company and the yarn industry to demonstrate their interest and knowledge.

- Review the company website, news articles, and social media pages.

- Learn about the company’s products, market position, and reputation.

- Understand the latest trends and developments in the yarn industry.

2. Highlight Relevant Skills and Experience:

Candidates should emphasize their skills and experience that are directly relevant to the Yarn Worker role.

- Quantify accomplishments using specific metrics, such as increased production efficiency or improved yarn quality.

- Provide examples of their ability to troubleshoot and resolve production issues.

- Highlight their experience in quality control and materials handling.

3. Demonstrate Process Optimization Mindset:

Interviewers value candidates who are proactive in identifying and implementing process improvements.

- Share examples of how they have successfully optimized processes in previous roles.

- Discuss their ideas for improving the production process at the company.

- Show enthusiasm for continuous improvement and innovation.

4. Dress Professionally and Arrive on Time:

First impressions matter. Candidates should dress professionally and arrive at the interview on time to show respect for the interviewers.

- Choose appropriate attire, such as a business suit or dress pants with a button-down shirt.

- Be punctual and plan their route to the interview location in advance.

- Bring a portfolio or resume to showcase their qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Yarn Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!