Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Yield Improvement Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

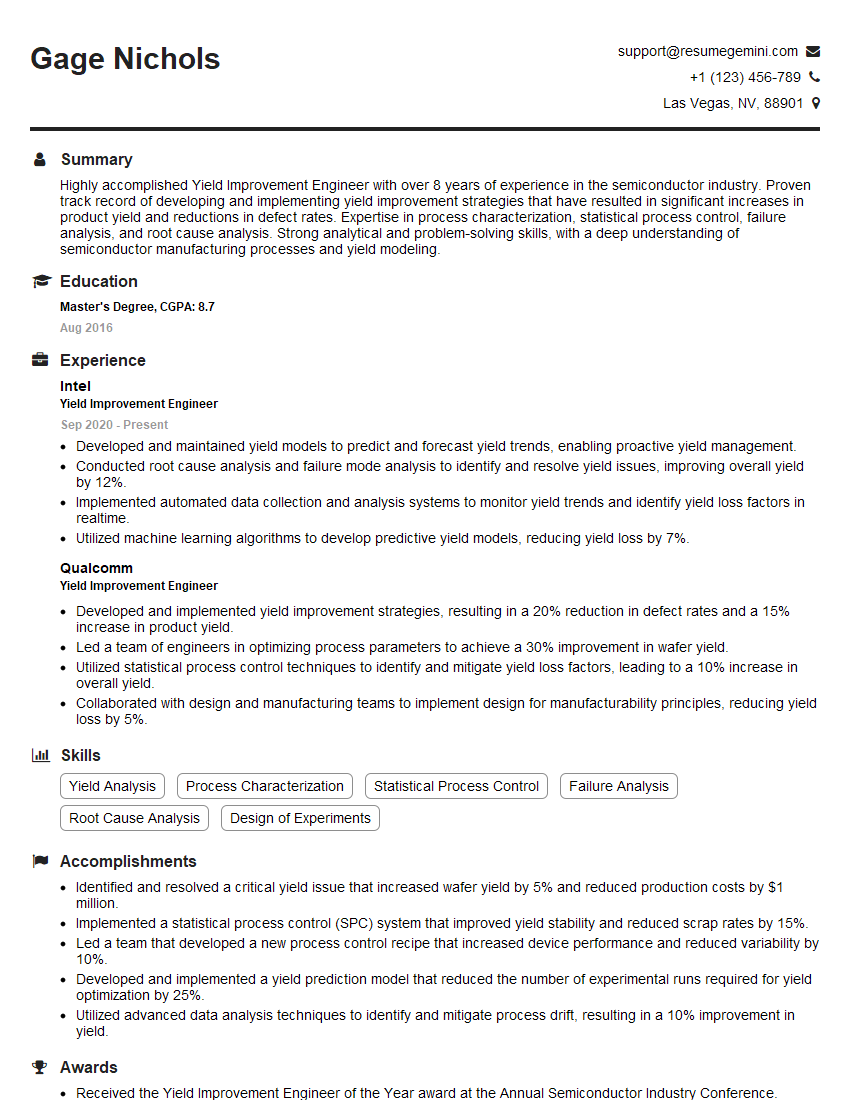

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yield Improvement Engineer

1. What are the steps involved in a typical yield improvement project?

In a typical yield improvement project, the following steps are involved:

- Data collection and analysis to identify the root cause of the yield loss

- Development of a corrective action plan to address the root cause

- Implementation of the corrective action plan and monitoring of the results

- Evaluation of the results and making necessary adjustments to the corrective action plan

- Closure of the project once the yield loss has been reduced to an acceptable level

2. What are the most common yield loss mechanisms in semiconductor manufacturing?

The most common yield loss mechanisms in semiconductor manufacturing include:

- Defects in the starting material

- Process variation

- Equipment failure

- Operator error

- Environmental contamination

3. What are the different types of yield loss analysis?

There are two main types of yield loss analysis:

- Statistical yield loss analysis, which uses statistical techniques to identify the root cause of the yield loss

- Physical yield loss analysis, which uses physical techniques to identify the root cause of the yield loss

4. What are the most important factors to consider when developing a corrective action plan?

The most important factors to consider when developing a corrective action plan include:

- The root cause of the yield loss

- The cost of implementing the corrective action

- The potential impact of the corrective action on other aspects of the manufacturing process

- The likelihood of the corrective action being successful

5. What are the most common challenges faced by yield improvement engineers?

The most common challenges faced by yield improvement engineers include:

- Lack of data

- Process complexity

- Equipment limitations

- Operator variability

- Cost constraints

6. What are the most important skills for a yield improvement engineer?

The most important skills for a yield improvement engineer include:

- Strong understanding of semiconductor manufacturing processes

- Excellent data analysis skills

- Ability to work in a team environment

- Excellent problem-solving skills

- Strong communication skills

7. What are the latest trends in yield improvement?

The latest trends in yield improvement include:

- Use of artificial intelligence (AI) and machine learning (ML) to identify and correct yield loss

- Development of new and innovative yield improvement techniques

- Increased focus on preventive yield loss

- Greater collaboration between yield improvement engineers and other members of the manufacturing team

8. What are the most important metrics for measuring yield improvement?

The most important metrics for measuring yield improvement include:

- Yield

- Yield loss

- Defect density

- Cycle time

- Cost

9. What are the most common yield improvement tools?

The most common yield improvement tools include:

- Statistical process control (SPC)

- Design of experiments (DOE)

- Failure analysis

- Yield modeling

- Simulation

10. What are the most important challenges facing the yield improvement industry?

The most important challenges facing the yield improvement industry include:

- Increasing complexity of semiconductor manufacturing processes

- Decreasing profit margins

- Global competition

- Shortage of skilled workers

- Rapidly changing technology

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yield Improvement Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yield Improvement Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The primary goal of a Yield Improvement Engineer is to optimize manufacturing processes to minimize defects and enhance product yield. Key responsibilities include:

1. Identify and Analyze Yield Loss

Understand and analyze manufacturing processes to identify areas of yield loss. Employ statistical tools and data analysis to pinpoint defects and their root causes.

- Collect and interpret data from production lines, inspection reports, and test results

- Identify trends and patterns in yield loss data

2. Develop and Implement Yield Improvement Plans

Design and execute strategies to reduce defects and improve yield. Collaborate with engineers, technicians, and production teams to implement process improvements and optimize equipment.

- Develop and test new manufacturing methods and technologies

- Monitor and evaluate the effectiveness of yield improvement initiatives

3. Characterization and Failure Analysis

Conduct thorough investigations into component failures and defects. Employ analytical techniques, microscopy, and other tools to determine the root causes of yield loss and provide recommendations for corrective actions.

- Analyze failed components to identify material flaws, design issues, or process defects

- Provide technical expertise and support to manufacturing and design teams

4. Process Monitoring and Control

Establish and maintain quality control systems to monitor and control manufacturing processes. Implement statistical process control (SPC) techniques to ensure consistent product quality and reduce variability.

- Establish process specifications and tolerances

- Monitor and analyze process data to identify deviations and trends

Interview Tips

To prepare effectively for a Yield Improvement Engineer interview, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s products, processes, and industry reputation. Understand the specific responsibilities and expectations of the Yield Improvement Engineer role.

- Visit the company’s website and social media pages

- Read industry news and publications

2. Highlight Your Technical Expertise

Emphasize your strong understanding of manufacturing processes, quality control techniques, and statistical analysis methods. Demonstrate your ability to analyze data, identify defects, and develop effective solutions.

- Provide specific examples of projects where you improved yield

- Discuss your knowledge of quality management systems such as ISO 9001

3. Showcase Analytical and Problem-Solving Skills

Highlight your ability to think critically, solve complex problems, and make data-driven decisions. Describe how you approach yield improvement challenges and what steps you take to identify and mitigate root causes.

- Explain how you use statistical tools to analyze data and identify trends

- Provide examples of innovative solutions you have implemented to improve yield

4. Demonstrate Communication and Teamwork Skills

Emphasize your ability to communicate effectively with engineers, technicians, and management. Explain how you collaborate with cross-functional teams to identify and resolve yield issues.

- Describe a situation where you successfully influenced stakeholders to implement process improvements

- Highlight your active listening and interpersonal skills

5. Prepare Industry-Specific Questions

Show your knowledge of the semiconductor industry and ask insightful questions that demonstrate your interest in the field. This could include questions about the company’s product roadmap, challenges in yield improvement, or emerging trends in semiconductor manufacturing.

- Ask about the company’s latest technological advancements

- Inquire about the team’s approach to yield management

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Yield Improvement Engineer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.