Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Zigzag Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

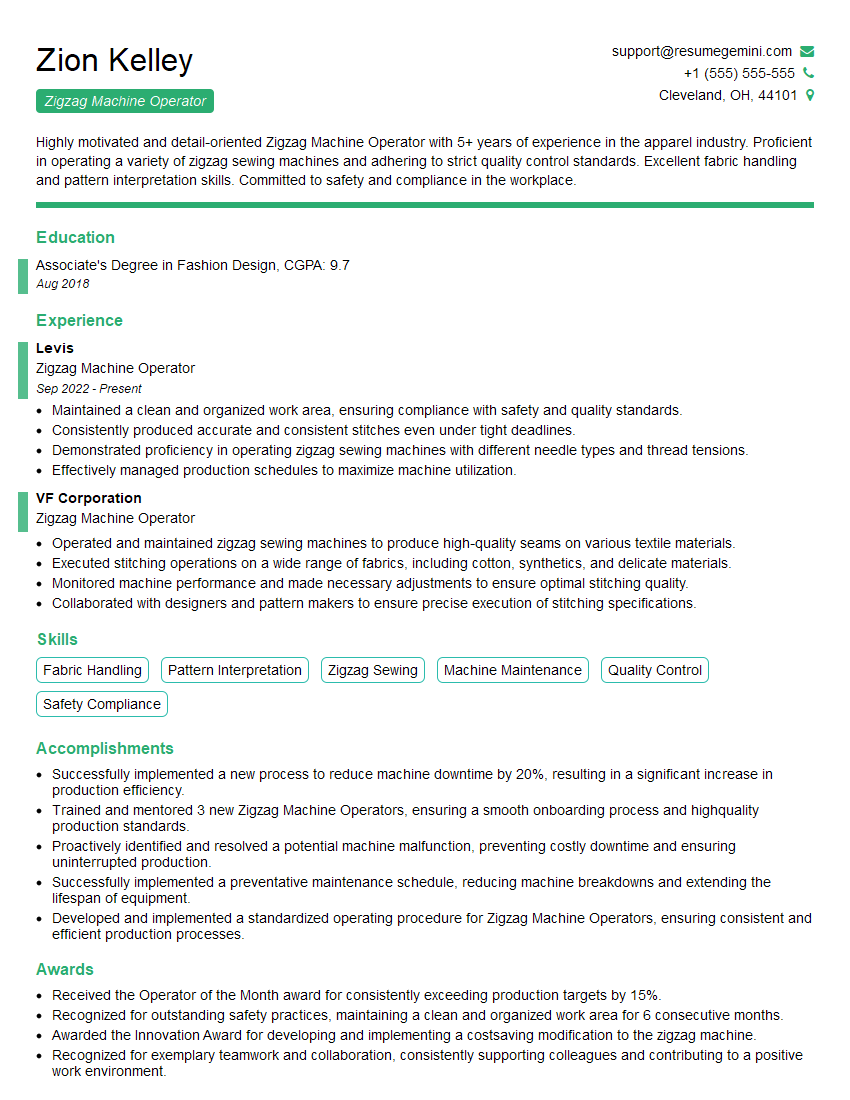

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Zigzag Machine Operator

1. What are the key responsibilities of a Zigzag Machine Operator?

- Operate and maintain zigzag sewing machines

- Interpret and follow work orders and technical drawings

- Set up and adjust machines according to specifications

- Inspect and ensure the quality of finished products

- Troubleshoot and resolve machine malfunctions

2. What types of fabrics and materials have you worked with on a zigzag machine?

subheading of the answer

- Woven fabrics (e.g., cotton, polyester, linen)

- Knitted fabrics (e.g., jersey, rib knit)

- Leather

- Vinyl

- Canvas

subheading of the answer

- Light-weight fabrics

- Medium-weight fabrics

- Heavy-weight fabrics

- Delicate fabrics

- Stretch fabrics

3. How do you ensure the quality of your work?

- Inspect the fabric before sewing to identify any defects

- Check the tension of the thread and adjust it as necessary

- Ensure that the stitch length and width are correct

- Sew a small sample piece to test the settings before proceeding with the entire project

- Inspect the finished product for any errors or defects

4. What is the most challenging aspect of operating a zigzag machine?

- Maintaining consistent stitch quality, especially on delicate fabrics

- Adjusting the machine settings to accommodate different fabrics and materials

- Troubleshooting and resolving machine malfunctions quickly and efficiently

- Meeting production deadlines while maintaining high quality standards

- Working with a variety of materials, each with its own unique properties

5. What are your strengths as a Zigzag Machine Operator?

- Excellent hand-eye coordination and precision

- Strong attention to detail and quality

- Ability to follow instructions and technical drawings accurately

- Experience in working with a variety of fabrics and materials

- Ability to troubleshoot and resolve machine malfunctions independently

6. What are your areas for improvement as a Zigzag Machine Operator?

- Improving my speed and efficiency without compromising quality

- Developing a deeper understanding of the mechanical aspects of the machine

- Expanding my experience working with specialized fabrics and materials

- Enhancing my ability to train and mentor new operators

- Staying up-to-date on the latest industry trends and advancements

7. How do you stay up-to-date on the latest techniques and best practices for zigzag machine operation?

- Attending industry conferences and workshops

- Reading trade publications and online forums

- Consulting with experienced operators and engineers

- Experimenting with different techniques and settings to find the best results

- Seeking feedback from supervisors and colleagues

8. What are the safety precautions that you follow when operating a zigzag machine?

- Wearing appropriate safety gear, such as safety glasses and gloves

- Inspecting the machine before each use to ensure that it is in good working order

- Never reaching into the machine while it is running

- Keeping the work area clean and free of obstructions

- Following all established safety protocols and procedures

9. How do you handle working under pressure and meeting deadlines?

- Prioritizing tasks and managing my time effectively

- Communicating with my supervisor and colleagues to ensure that everyone is aware of the deadlines

- Working efficiently and accurately to meet production targets

- Staying calm and focused under pressure

- Seeking assistance from my team when needed

10. Why are you interested in working as a Zigzag Machine Operator for our company?

- Your company is a reputable and well-established leader in the industry

- I am impressed by your commitment to quality and innovation

- I believe that my skills and experience would be a valuable asset to your team

- I am eager to learn and grow within your company

- I am confident that I can make a significant contribution to your continued success

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Zigzag Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Zigzag Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Zigzag Machine Operator is responsible for operating a zigzag sewing machine to sew different types of fabrics and materials. They are expected to maintain the machine, ensure its proper functioning, and produce high-quality sewn products. Key job responsibilities include:

1. Operating the Zigzag Sewing Machine

Operate the zigzag sewing machine to sew seams, hems, and other types of stitches on fabrics and materials. Ensure the machine is properly threaded and calibrated to produce precise and consistent stitches.

2. Maintaining the Machine

Perform regular maintenance and cleaning of the zigzag sewing machine. Lubricate moving parts, check tension settings, and replace needles and other components as needed to ensure optimal performance.

3. Troubleshooting and Problem-Solving

Identify and resolve any issues that may arise during operation. Troubleshoot problems related to thread tension, stitch quality, and machine malfunctions to minimize downtime and maintain productivity.

4. Producing High-Quality Sewn Products

Produce high-quality sewn products that meet the required specifications. Ensure stitches are even, seams are secure, and the overall appearance of the finished product meets customer expectations.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some crucial interview tips to help you ace your Zigzag Machine Operator interview:

1. Research the Company and Role

Take the time to research the company you’re applying to, its industry, and the specific role you’re interviewing for. This will help you understand the company’s culture, values, and the requirements of the position, allowing you to tailor your answers accordingly.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you articulate your skills, experience, and qualifications effectively. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your work.

3. Emphasize Relevant Skills and Experience

Highlight your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible using specific metrics and results to demonstrate your impact in previous roles.

4. Demonstrate Your Knowledge of Zigzag Machines

Showcase your knowledge of zigzag sewing machines, including their functionality, maintenance, and troubleshooting techniques. Explain how you ensure the production of high-quality sewn products using this equipment.

5. Ask Thoughtful Questions

During the interview, don’t hesitate to ask thoughtful questions about the company, the role, and the industry. This demonstrates your interest and engagement, and gives you an opportunity to clarify any uncertainties you may have.

6. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. Maintain a positive and confident demeanor throughout the process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Zigzag Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!