Feeling lost in a sea of interview questions? Landed that dream interview for Zinc Plate Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Zinc Plate Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

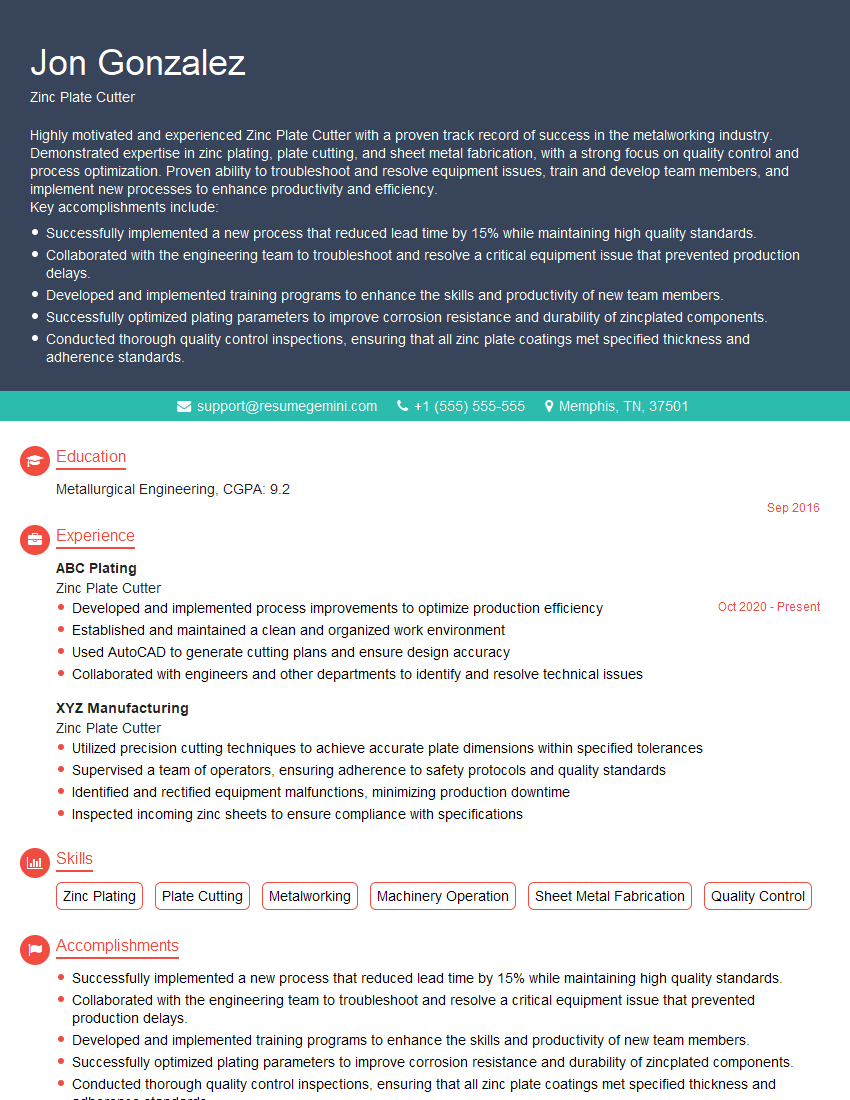

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Zinc Plate Cutter

1. What are the different types of zinc plating processes?

There are three main types of zinc plating processes: electrolytic, hot-dip galvanizing, and Sherardizing. Electrolytic zinc plating is the most common and involves passing an electric current through a zinc anode and a zinc electrolyte solution. Hot-dip galvanizing involves dipping the metal to be plated into a molten zinc bath. Sherardizing involves tumbling the metal to be plated in a zinc dust bath.

2. What are the advantages and disadvantages of each zinc plating process?

Electrolytic zinc plating

- Advantages:

- Produces a thin, uniform coating

- Can be used to plate a variety of metals

- Relatively inexpensive

- Disadvantages:

- Can be brittle

- Not as corrosion-resistant as other zinc plating processes

Hot-dip galvanizing

- Advantages:

- Produces a thick, durable coating

- Excellent corrosion resistance

- Can be used to plate large objects

- Disadvantages:

- Can be expensive

- Can produce a rough finish

- Can distort the metal being plated

Sherardizing

- Advantages:

- Produces a thin, uniform coating

- Excellent corrosion resistance

- Can be used to plate a variety of metals

- Relatively inexpensive

- Disadvantages:

- Can be slow

- Not as durable as other zinc plating processes

3. What are the different factors that affect the quality of a zinc plating?

- The type of zinc plating process used

- The thickness of the zinc coating

- The surface preparation of the metal being plated

- The temperature of the plating solution

- The current density

4. What are the different applications for zinc plating?

- Corrosion protection

- Electrical conductivity

- Soldering and brazing

- Automotive parts

- Construction materials

5. What are the safety precautions that should be taken when working with zinc plating?

- Wear gloves, eye protection, and a respirator

- Handle zinc plating chemicals with care

- Dispose of zinc plating waste properly

6. What are the different types of zinc plate cutters?

- Manual zinc plate cutters

- Electric zinc plate cutters

- Pneumatic zinc plate cutters

- Hydraulic zinc plate cutters

7. What are the different factors to consider when choosing a zinc plate cutter?

- The thickness of the zinc plate being cut

- The desired cutting speed

- The accuracy of the cut

- The portability of the cutter

- The cost of the cutter

8. How do you operate a zinc plate cutter?

The operation of a zinc plate cutter will vary depending on the type of cutter being used. However, some general steps that are common to most zinc plate cutters include:

- Secure the zinc plate in the cutter

- Set the cutting speed and accuracy

- Start the cutter and guide it along the desired cutting line

- Stop the cutter and remove the cut zinc plate

9. What are the different types of zinc plate cutter blades?

- High-speed steel blades

- Carbide blades

- Diamond blades

10. How do you maintain a zinc plate cutter?

- Clean the cutter regularly

- Sharpen the blades as needed

- Lubricate the cutter according to the manufacturer’s instructions

- Inspect the cutter for damage regularly

11. What are the different types of zinc plate cutter accessories?

- Dust collection systems

- Blade guards

- Safety glasses

12. What are the different safety precautions that should be taken when using a zinc plate cutter?

- Wear gloves, eye protection, and a respirator

- Keep the cutter away from flammable materials

- Do not operate the cutter if it is damaged

- Follow the manufacturer’s instructions for safe operation

13. What are the different types of zinc plate cutter manufacturers?

- Haco

- Shearmaster

- Tippmann

- Piranha

- Amada

14. What are the different factors to consider when choosing a zinc plate cutter manufacturer?

- The reputation of the manufacturer

- The quality of the cutters

- The price of the cutters

- The availability of customer support

15. What are the different trends in the zinc plate cutter market?

- The increasing demand for zinc plate cutters in the automotive industry

- The development of new and innovative zinc plate cutter technologies

- The growing popularity of online zinc plate cutter retailers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Zinc Plate Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Zinc Plate Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Zinc Plate Cutters are responsible for cutting zinc plates into specific shapes and sizes. They use a variety of tools and equipment to complete their tasks, including shears, saws, and grinders.

1. Cutting Zinc Plates

The primary responsibility of a Zinc Plate Cutter is to cut zinc plates into specific shapes and sizes. This may involve using a variety of tools and equipment, including shears, saws, and grinders.

- Use shears to cut straight lines in zinc plates.

- Use saws to cut curves and irregular shapes in zinc plates.

- Use grinders to smooth the edges of zinc plates.

2. Measuring and Marking Zinc Plates

Before cutting zinc plates, Zinc Plate Cutters must measure and mark them to ensure that they are cut to the correct size and shape. This may involve using a variety of tools, including rulers, tape measures, and marking pens.

- Use rulers and tape measures to measure the length and width of zinc plates.

- Use marking pens to mark the cutting lines on zinc plates.

3. Inspecting Zinc Plates

After cutting zinc plates, Zinc Plate Cutters must inspect them to ensure that they meet the required specifications. This may involve checking for burrs, sharp edges, and other defects.

- Inspect zinc plates for burrs and sharp edges.

- Check zinc plates for other defects, such as cracks or holes.

4. Maintaining Equipment

Zinc Plate Cutters are responsible for maintaining their own equipment, including shears, saws, and grinders. This may involve cleaning, oiling, and repairing equipment as needed.

- Clean and oil equipment regularly.

- Repair equipment as needed.

Interview Tips

Preparing for an interview for a Zinc Plate Cutter position can help you make a good impression on the interviewer and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the Company and the Position

Before the interview, take some time to research the company and the Zinc Plate Cutter position. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read online reviews of the company to get an idea of what it’s like to work there.

- Search for news articles about the company to learn about its recent developments and financial performance.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked in an interview for a Zinc Plate Cutter position. It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Tell me about your experience cutting zinc plates.

- What are your strengths and weaknesses as a Zinc Plate Cutter?

- Why are you interested in working for our company?

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Wear a suit or dress pants and a button-down shirt or blouse.

- Make sure your clothes are clean and pressed.

- Choose shoes that are comfortable and professional.

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Plan to arrive at the interview location 10-15 minutes early so that you have time to check in and compose yourself.

- Give yourself plenty of time to get to the interview location.

- Factor in traffic and parking when planning your route.

- If you are running late, call or email the interviewer to let them know.

Next Step:

Now that you’re armed with the knowledge of Zinc Plate Cutter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Zinc Plate Cutter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini