Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Zyglo Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Zyglo Inspector so you can tailor your answers to impress potential employers.

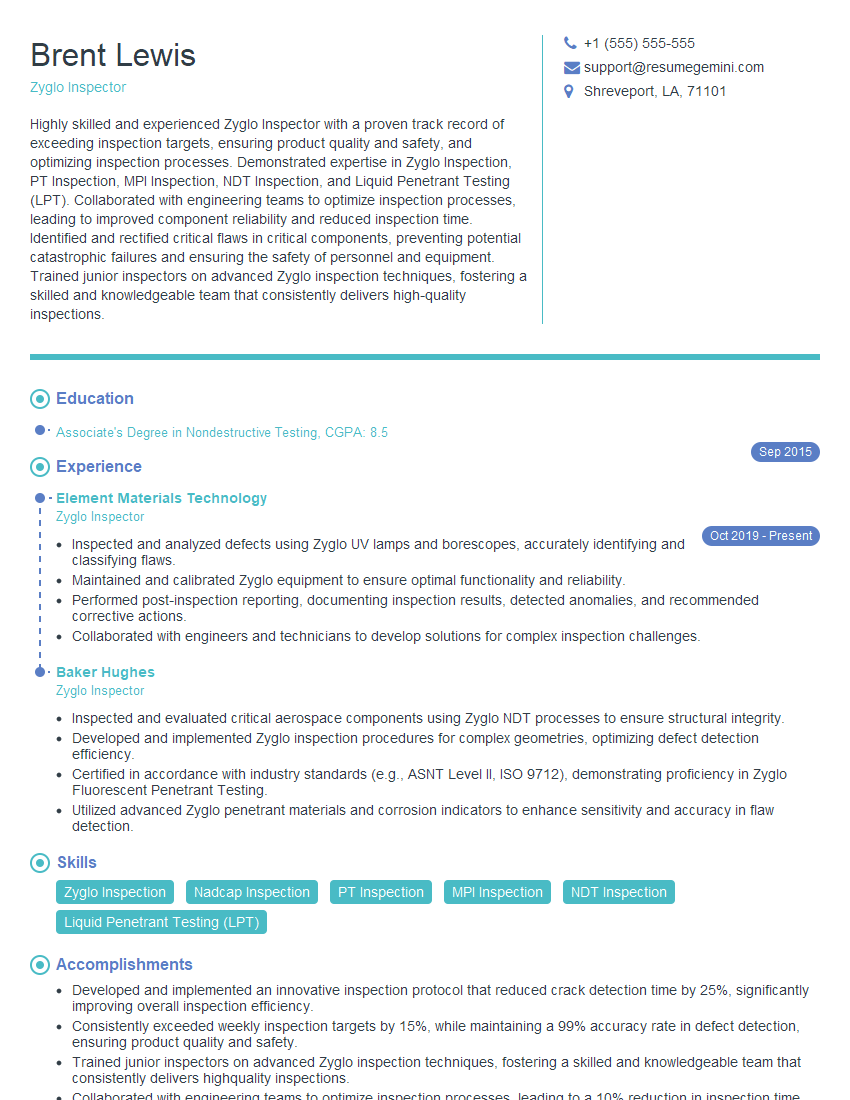

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Zyglo Inspector

1. Explain the process of Zyglo inspection, including the preparation, application, and evaluation of results?

- Zyglo inspection is a non-destructive testing (NDT) method used to detect surface-breaking defects in ferrous materials.

- The process involves cleaning the surface to remove any contaminants, applying a penetrant, allowing it to dwell, removing excess penetrant, and applying a developer.

- The penetrant seeps into any surface-breaking defects, and the developer draws the penetrant out of the defects, making them visible under ultraviolet (UV) light.

2. What are the different types of penetrants used in Zyglo inspection, and when should each type be used?

Water-washable penetrants

- As the name suggests, these penetrants are removed using water.

- They are ideal for non-porous surfaces or surfaces that can be easily rinsed with water.

Solvent-removable penetrants

- These penetrants are removed using a solvent.

- They are suitable for porous surfaces or surfaces that cannot be rinsed with water.

Post-emulsifiable penetrants

- These penetrants are removed using both water and an emulsifier.

- They are used for critical inspections or when high sensitivity is required.

3. What are the factors that affect the sensitivity of Zyglo inspection?

- Penetrant type and dwell time

- Surface preparation and cleanliness

- Developer type and application

- UV light intensity and wavelength

- Inspector experience and training

4. What are the limitations of Zyglo inspection?

- Only detects surface-breaking defects

- May not be suitable for all materials

- Requires clean and dry surfaces

- Can be time-consuming, especially for large or complex components

5. How do you calibrate and maintain Zyglo inspection equipment?

- UV light intensity: Use a UV light meter to ensure the light intensity meets the specified requirements.

- Penetrant dwell time: Follow the manufacturer’s instructions for the specific penetrant being used.

- Developer application: Ensure the developer is applied evenly and according to the manufacturer’s specifications.

- Regular cleaning and maintenance: Keep all equipment clean and in good working condition to ensure accurate results.

6. What are the safety precautions that should be taken when performing Zyglo inspection?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a lab coat.

- Work in a well-ventilated area to avoid inhaling fumes.

- Handle penetrants and developers with care as they may contain hazardous chemicals.

- Dispose of waste materials properly according to local regulations.

7. What are the different types of defects that can be detected using Zyglo inspection?

- Cracks

- Porosity

- Inclusions

- Tears

- Corrosion

8. What are the advantages of using Zyglo inspection over other NDT methods?

- High sensitivity to surface-breaking defects

- Relatively easy to perform and requires minimal equipment

- Can be used on a wide range of materials

- Provides a permanent record of the inspection

9. What are the challenges of performing Zyglo inspection in the field?

- Ensuring clean and dry surfaces in outdoor environments

- Dealing with varying light conditions and temperatures

- Carrying and protecting equipment in remote or hazardous locations

- Interpreting results in real-time and making critical decisions

10. Describe a situation where you successfully used Zyglo inspection to detect a critical defect in a component.

- Provide a brief description of the component and the specific application.

- Explain how you prepared the surface, applied the penetrant, and evaluated the results.

- Describe the type of defect you detected and how it was critical to the component’s integrity.

- Explain the impact of your findings and the subsequent actions taken.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Zyglo Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Zyglo Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Zyglo Inspectors are responsible for ensuring the quality of manufactured parts by performing visual and nondestructive testing (NDT) using Zyglo fluorescent penetrant inspection (FPI) methods. Their duties include:

1. Visual Inspection and Preparation

Examining components visually for surface defects, such as cracks, scratches, and corrosion.

- Cleaning and preparing surfaces to ensure proper penetration of the Zyglo penetrant.

- Masking off areas that should not be inspected.

2. Penetrant Application

Applying the Zyglo penetrant to the surface of the component and allowing it to dwell for a specified time.

- Selecting the appropriate penetrant for the material and type of defect being inspected.

- Monitoring the dwell time to ensure optimal penetration.

3. Excess Penetrant Removal

Removing excess penetrant from the surface using a water-soluble emulsifier or solvent.

- Adjusting the emulsifier concentration and spray pressure to effectively remove excess penetrant without washing away indications.

- Inspecting the surface visually to ensure complete removal.

4. Developer Application

Applying a developer to the surface to draw out the penetrant from defects and create visible indications.

- Selecting the appropriate developer for the application and material.

- Monitoring the development time to ensure optimal indication contrast.

5. Inspection and Reporting

Examining the developed surface under ultraviolet (UV) light to identify and evaluate indications.

- Interpreting and classifying indications based on their size, shape, and location.

- Documenting and reporting inspection results, including any defects or anomalies detected.

Interview Tips

To ace an interview for a Zyglo Inspector position, candidates should:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products or services, and industry trends. This shows your enthusiasm for the role and willingness to contribute to the organization’s success.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in visual inspection, nondestructive testing techniques (specifically Zyglo FPI), and quality control processes. Provide specific examples of projects where you successfully identified and categorized defects.

3. Showcase Attention to Detail and Accuracy

Stress your ability to meticulously examine components, follow procedures precisely, and interpret indications accurately. Explain how your attention to detail ensures reliable inspection results.

4. Demonstrate Problem-Solving and Reporting Abilities

Describe situations where you identified defects or anomalies and effectively communicated your findings to stakeholders. Emphasize your ability to collaborate with engineers and production teams to resolve quality issues.

5. Prepare Questions for the Interviewer

Preparing thoughtful questions to ask the interviewer demonstrates your engagement and interest in the role. Ask about the company’s quality standards, the typical workload and challenges of the position, and opportunities for professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Zyglo Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.