Are you gearing up for an interview for a Zyglo Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Zyglo Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

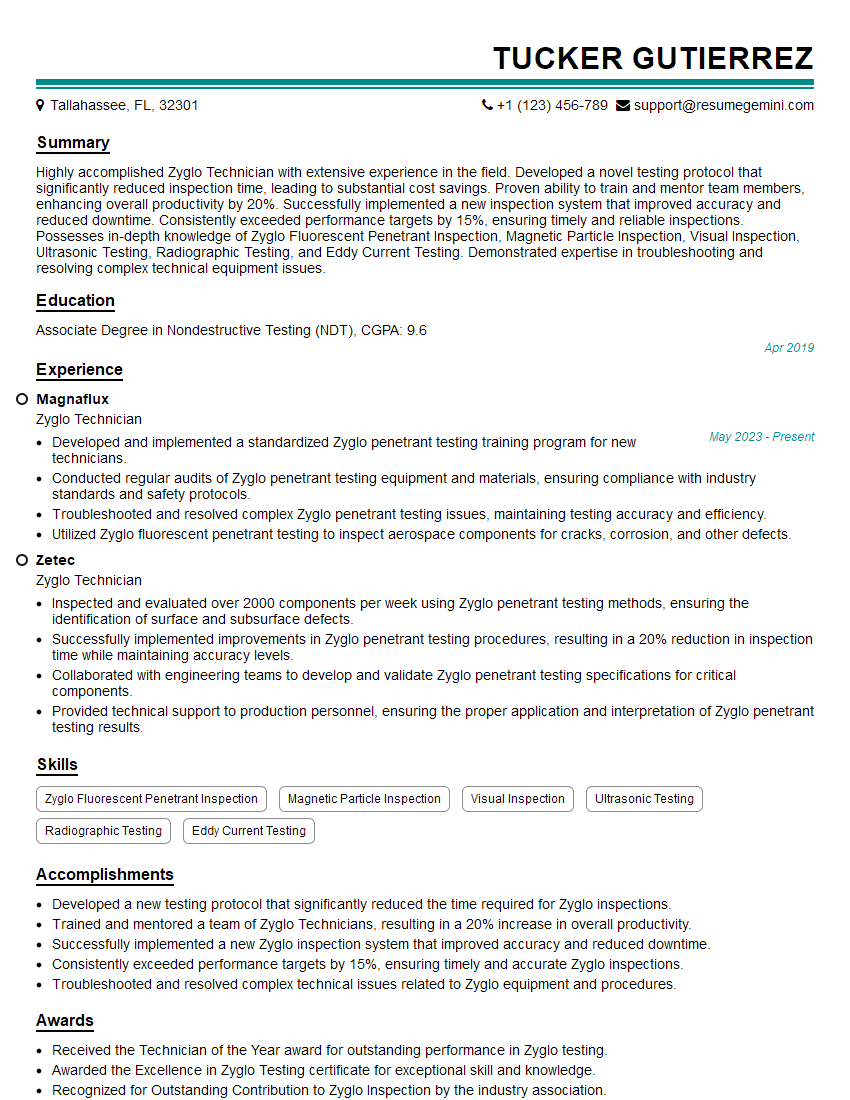

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Zyglo Technician

1. Explain the Zyglo process and its applications.

The Zyglo process is a non-destructive testing method used to detect surface defects on various materials, particularly metallic components.

- It involves applying a fluorescent penetrant to the surface, allowing it to penetrate any defects.

- Excess penetrant is removed, and a developer is applied, which draws the penetrant from the defects, making them visible under ultraviolet light.

- Zyglo is widely used in industries such as aerospace, automotive, oil and gas, and manufacturing to detect cracks, porosity, corrosion, and other imperfections.

2. Describe the different types of Zyglo penetrants and their uses.

Water-washable penetrants

- Most commonly used

- Easily removed with water

- Suitable for inspections in areas where post-cleaning is required

Solvent-removable penetrants

- Used on non-porous surfaces

- Removed with solvents

- May leave residue after cleaning

Post-emulsifiable penetrants

- Form an emulsion when mixed with water

- Can be removed with water or solvents

- Suitable for inspections where both water-washable and solvent-removable properties are required

3. How do you prepare a surface for Zyglo inspection?

- Clean the surface thoroughly to remove any dirt, grease, or other contaminants

- Dry the surface completely

- Apply a thin layer of penetrant to the surface and allow it to dwell for the specified time

- Remove excess penetrant using a clean cloth or paper towels

- Apply a developer to the surface and allow it to draw out the penetrant from any defects

4. How do you interpret Zyglo results?

After applying a developer, examine the surface under ultraviolet light.

- Fluorescent indications on the surface indicate the presence of defects.

- The size, shape, and distribution of the indications can provide information about the type and severity of the defect.

- It is important to distinguish between relevant indications and background fluorescence.

5. What are the limitations of the Zyglo process?

- Only detects surface defects

- May not be suitable for very rough or porous surfaces

- Fluorescent background may interfere with interpretation in some cases

- Requires proper lighting and equipment for accurate results

6. What safety precautions should be followed when using Zyglo?

- Wear appropriate protective gear, including gloves, eye protection, and respiratory protection

- Avoid skin contact with penetrants and developers

- Work in a well-ventilated area

- Dispose of used penetrants and developers properly

7. What are the advantages of Zyglo over other NDT methods?

- High sensitivity for detecting surface defects

- Non-destructive, preserving the integrity of the component

- Relatively quick and easy to perform

- Portable, allowing inspections in various locations

- Widely applicable to different materials and industries

8. What are some of the challenges you have faced as a Zyglo technician?

- Interpreting results on complex or irregular surfaces

- Dealing with background fluorescence or interference from other sources

- Ensuring proper preparation and application of Zyglo materials

- Maintaining a clean and safe work environment

- Staying up-to-date with industry standards and best practices

9. Describe a situation where you used the Zyglo process to solve a specific problem.

- Provide a brief overview of the problem

- Explain how you prepared the surface and applied the Zyglo materials

- Describe the results you obtained and how you interpreted them

- State what actions were taken based on your findings

10. What are your future career goals as a Zyglo technician?

- Gaining more experience and becoming certified in the field

- Staying abreast of technological advancements in NDT

- Exploring opportunities in different industries to apply my skills

- Contributing to research and development of improved Zyglo techniques

- Advancing to a supervisory or management role

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Zyglo Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Zyglo Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Zyglo Technicians are responsible for performing fluorescent penetrant inspections (FPI), also known as Zyglo inspections.

Zyglo is a non-destructive testing method that utilizes a fluorescent dye to detect surface-breaking defects in various materials.

1. Inspection Setup

Prepare and set up the inspection area.

- Ensure a clean and well-lit workspace.

- Properly place and secure the part to be inspected.

2. Application of Penetrant

Apply the fluorescent penetrant to the surface of the part.

- Immerse the part in the penetrant or spray it using a certified penetrant spray.

- Allow the penetrant to dwell for a specified period, allowing it to seep into any surface-breaking defects.

3. Removal of Excess Penetrant

Remove excess penetrant from the surface of the part using appropriate methods.

- Wipe the surface with a clean cloth or absorbent paper.

- Use a penetrant remover to dissolve and remove excess penetrant.

4. Application of Developer

Apply a developer to the surface of the part.

- Spray or brush on the developer.

- Allow the developer to dwell for a specified period, drawing the penetrant from any defects to the surface.

5. Inspection and Interpretation

Inspect the part under ultraviolet light to detect fluorescent indications.

- Use a UV lamp or black light.

- Interpret the indications and identify surface-breaking defects.

6. Reporting

Prepare and document inspection results.

- Record the location, size, and type of defects found.

- Submit inspection reports or provide verbal feedback to supervisors or customers.

Interview Tips

Preparing for a Zyglo Technician interview requires a combination of technical knowledge, understanding of the industry, and effective communication skills.

Here are a few tips to help you ace your interview.

1. Research the Role and Company

Thoroughly read the job description and research the company and industry to understand their specific requirements and the nature of the position.

Knowing the company’s products, services, and reputation will demonstrate your interest and commitment to the opportunity.

2. Practice Your Technical Skills

Review the principles of fluorescent penetrant inspection and brush up on the techniques. Be prepared to discuss the step-by-step process and the equipment used in conducting Zyglo inspections.

3. Highlight Your Experience

Emphasize your previous experience in non-destructive testing, particularly in Zyglo or NDT techniques. If you have industry certifications or training, be sure to mention them and explain their significance.

4. Showcase Your Attention to Detail

Zyglo inspections require meticulous attention to detail and precision. Highlight your ability to follow procedures carefully, identify defects accurately, and produce clear and concise reports.

5. Prepare for Common Interview Questions

Practice answering common interview questions related to the role. Prepare examples that demonstrate your skills, such as:

- Tell me a situation where you had to troubleshoot an issue during a Zyglo inspection.

- How do you ensure the accuracy and reliability of your inspection results?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Zyglo Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!