Are you a seasoned Acid Tank Liner seeking a new career path? Discover our professionally built Acid Tank Liner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

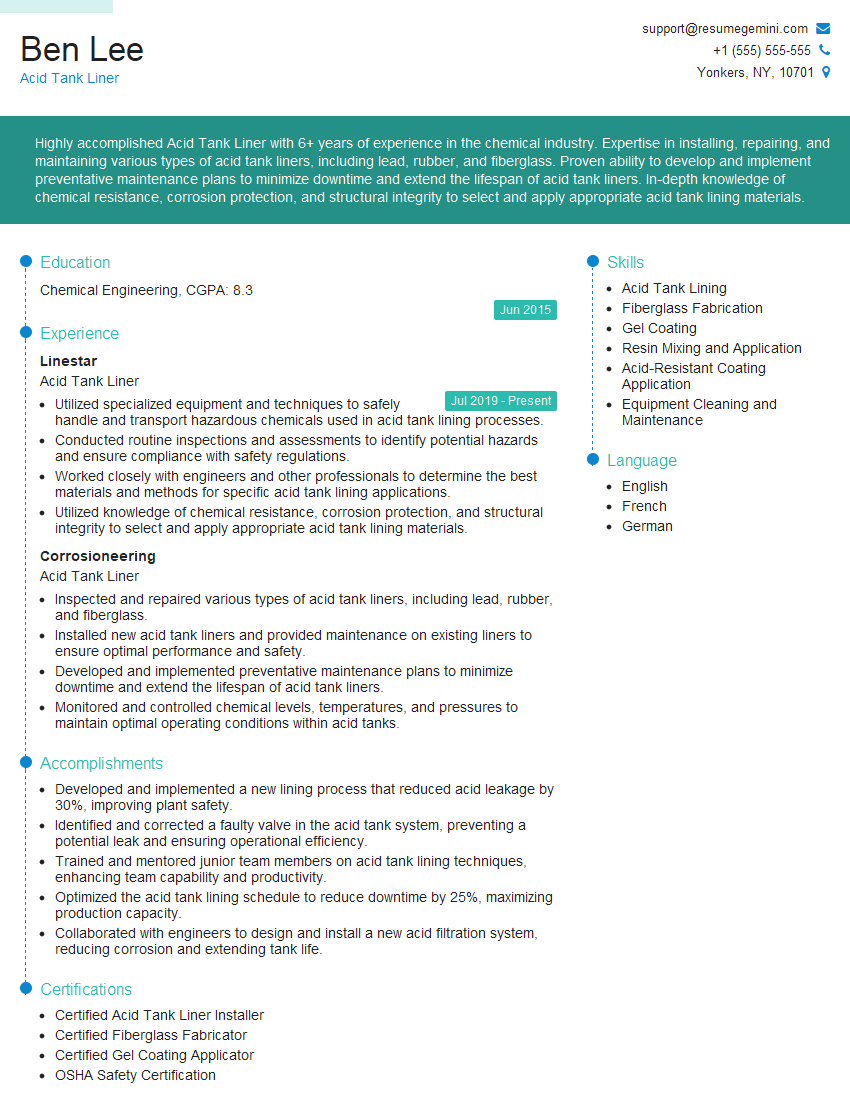

Ben Lee

Acid Tank Liner

Summary

Highly accomplished Acid Tank Liner with 6+ years of experience in the chemical industry. Expertise in installing, repairing, and maintaining various types of acid tank liners, including lead, rubber, and fiberglass. Proven ability to develop and implement preventative maintenance plans to minimize downtime and extend the lifespan of acid tank liners. In-depth knowledge of chemical resistance, corrosion protection, and structural integrity to select and apply appropriate acid tank lining materials.

Education

Chemical Engineering

June 2015

Skills

- Acid Tank Lining

- Fiberglass Fabrication

- Gel Coating

- Resin Mixing and Application

- Acid-Resistant Coating Application

- Equipment Cleaning and Maintenance

Work Experience

Acid Tank Liner

- Utilized specialized equipment and techniques to safely handle and transport hazardous chemicals used in acid tank lining processes.

- Conducted routine inspections and assessments to identify potential hazards and ensure compliance with safety regulations.

- Worked closely with engineers and other professionals to determine the best materials and methods for specific acid tank lining applications.

- Utilized knowledge of chemical resistance, corrosion protection, and structural integrity to select and apply appropriate acid tank lining materials.

Acid Tank Liner

- Inspected and repaired various types of acid tank liners, including lead, rubber, and fiberglass.

- Installed new acid tank liners and provided maintenance on existing liners to ensure optimal performance and safety.

- Developed and implemented preventative maintenance plans to minimize downtime and extend the lifespan of acid tank liners.

- Monitored and controlled chemical levels, temperatures, and pressures to maintain optimal operating conditions within acid tanks.

Accomplishments

- Developed and implemented a new lining process that reduced acid leakage by 30%, improving plant safety.

- Identified and corrected a faulty valve in the acid tank system, preventing a potential leak and ensuring operational efficiency.

- Trained and mentored junior team members on acid tank lining techniques, enhancing team capability and productivity.

- Optimized the acid tank lining schedule to reduce downtime by 25%, maximizing production capacity.

- Collaborated with engineers to design and install a new acid filtration system, reducing corrosion and extending tank life.

Certificates

- Certified Acid Tank Liner Installer

- Certified Fiberglass Fabricator

- Certified Gel Coating Applicator

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Acid Tank Liner

- Showcase your experience and skills in installing, repairing, and maintaining various types of acid tank liners.

- Highlight your knowledge of chemical resistance, corrosion protection, and structural integrity.

- Emphasize your ability to develop and implement preventative maintenance plans to minimize downtime.

- Mention any certifications or training programs you have completed in the field of acid tank lining.

Essential Experience Highlights for a Strong Acid Tank Liner Resume

- Inspected and repaired various types of acid tank liners, including lead, rubber, and fiberglass.

- Installed new acid tank liners and provided maintenance on existing liners.

- Developed and implemented preventative maintenance plans.

- Monitored and controlled chemical levels, temperatures, and pressures.

- Utilized specialized equipment and techniques to safely handle and transport hazardous chemicals.

- Conducted routine inspections and assessments to identify potential hazards.

Frequently Asked Questions (FAQ’s) For Acid Tank Liner

What are the different types of acid tank liners?

The most common types of acid tank liners are lead, rubber, and fiberglass. Each type has its own advantages and disadvantages, so the best choice for a particular application will depend on the specific requirements.

What are the most important factors to consider when selecting an acid tank liner?

The most important factors to consider when selecting an acid tank liner are the chemical resistance, corrosion protection, and structural integrity of the material.

How often should acid tank liners be inspected?

Acid tank liners should be inspected regularly, at least once a year, to identify any potential problems.

What are the most common causes of acid tank liner failure?

The most common causes of acid tank liner failure are improper installation, corrosion, and mechanical damage.

What are the consequences of acid tank liner failure?

Acid tank liner failure can lead to leakage of hazardous chemicals, which can pose a serious safety hazard.