Are you a seasoned Advanced Manufacturing Consultant seeking a new career path? Discover our professionally built Advanced Manufacturing Consultant Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

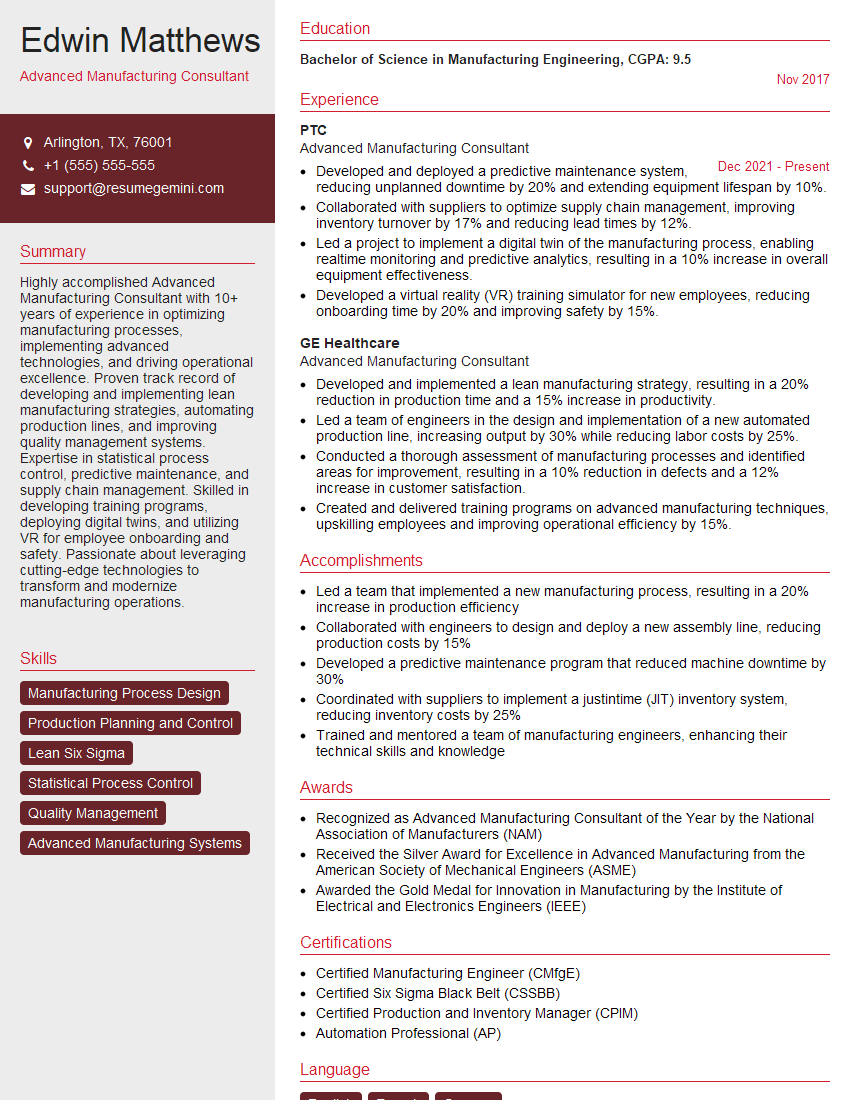

Edwin Matthews

Advanced Manufacturing Consultant

Summary

Highly accomplished Advanced Manufacturing Consultant with 10+ years of experience in optimizing manufacturing processes, implementing advanced technologies, and driving operational excellence. Proven track record of developing and implementing lean manufacturing strategies, automating production lines, and improving quality management systems. Expertise in statistical process control, predictive maintenance, and supply chain management. Skilled in developing training programs, deploying digital twins, and utilizing VR for employee onboarding and safety. Passionate about leveraging cutting-edge technologies to transform and modernize manufacturing operations.

Education

Bachelor of Science in Manufacturing Engineering

November 2017

Skills

- Manufacturing Process Design

- Production Planning and Control

- Lean Six Sigma

- Statistical Process Control

- Quality Management

- Advanced Manufacturing Systems

Work Experience

Advanced Manufacturing Consultant

- Developed and deployed a predictive maintenance system, reducing unplanned downtime by 20% and extending equipment lifespan by 10%.

- Collaborated with suppliers to optimize supply chain management, improving inventory turnover by 17% and reducing lead times by 12%.

- Led a project to implement a digital twin of the manufacturing process, enabling realtime monitoring and predictive analytics, resulting in a 10% increase in overall equipment effectiveness.

- Developed a virtual reality (VR) training simulator for new employees, reducing onboarding time by 20% and improving safety by 15%.

Advanced Manufacturing Consultant

- Developed and implemented a lean manufacturing strategy, resulting in a 20% reduction in production time and a 15% increase in productivity.

- Led a team of engineers in the design and implementation of a new automated production line, increasing output by 30% while reducing labor costs by 25%.

- Conducted a thorough assessment of manufacturing processes and identified areas for improvement, resulting in a 10% reduction in defects and a 12% increase in customer satisfaction.

- Created and delivered training programs on advanced manufacturing techniques, upskilling employees and improving operational efficiency by 15%.

Accomplishments

- Led a team that implemented a new manufacturing process, resulting in a 20% increase in production efficiency

- Collaborated with engineers to design and deploy a new assembly line, reducing production costs by 15%

- Developed a predictive maintenance program that reduced machine downtime by 30%

- Coordinated with suppliers to implement a justintime (JIT) inventory system, reducing inventory costs by 25%

- Trained and mentored a team of manufacturing engineers, enhancing their technical skills and knowledge

Awards

- Recognized as Advanced Manufacturing Consultant of the Year by the National Association of Manufacturers (NAM)

- Received the Silver Award for Excellence in Advanced Manufacturing from the American Society of Mechanical Engineers (ASME)

- Awarded the Gold Medal for Innovation in Manufacturing by the Institute of Electrical and Electronics Engineers (IEEE)

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Six Sigma Black Belt (CSSBB)

- Certified Production and Inventory Manager (CPIM)

- Automation Professional (AP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Advanced Manufacturing Consultant

Quantify your accomplishments:

Use specific metrics and data to demonstrate the impact of your contributions and the value you have brought to previous organizations.Highlight your technical expertise:

Showcase your proficiency in advanced manufacturing technologies, such as lean six sigma, statistical process control, and automated production systems.Emphasize your ability to drive change:

Describe projects where you successfully implemented innovative solutions, overcame challenges, and improved overall manufacturing performance.Showcase your communication and interpersonal skills:

Highlight your ability to effectively communicate technical concepts, collaborate with cross-functional teams, and build strong relationships with stakeholders.Include industry certifications:

Include any relevant certifications, such as Certified Lean Six Sigma Black Belt or Project Management Professional (PMP), to demonstrate your commitment to professional development and industry standards.

Essential Experience Highlights for a Strong Advanced Manufacturing Consultant Resume

- Develop and implement lean manufacturing strategies and methodologies to optimize production processes, reduce waste, and improve efficiency.

- Design and implement automated production lines using robotics, automation equipment, and advanced manufacturing systems to increase output, reduce labor costs, and improve quality.

- Conduct thorough assessments of existing manufacturing processes, identify areas for improvement, and develop and execute plans to address inefficiencies and enhance performance.

- Create and deliver comprehensive training programs on advanced manufacturing techniques to upskill employees, improve operational efficiency, and foster a culture of continuous improvement.

- Design and deploy predictive maintenance systems to monitor equipment health, predict failures, and implement proactive maintenance strategies to minimize downtime and extend equipment lifespan.

- Collaborate with suppliers and stakeholders across the supply chain to optimize inventory management, improve delivery times, and reduce overall procurement costs.

- Utilize digital twin technologies to create virtual representations of manufacturing processes, enabling real-time monitoring, predictive analytics, and data-driven decision-making.

Frequently Asked Questions (FAQ’s) For Advanced Manufacturing Consultant

What are the key skills required to be a successful Advanced Manufacturing Consultant?

Successful Advanced Manufacturing Consultants possess a deep understanding of manufacturing processes, advanced manufacturing technologies, and lean manufacturing principles. They are proficient in statistical process control, quality management, and predictive maintenance. Additionally, strong communication, problem-solving, and analytical skills are essential.

What industries can benefit from Advanced Manufacturing Consulting services?

Advanced Manufacturing Consulting services can benefit a wide range of industries, including automotive, aerospace, electronics, healthcare, and consumer goods. Any industry seeking to optimize its manufacturing operations, improve efficiency, and leverage advanced technologies can benefit from consulting support.

How can Advanced Manufacturing Consulting help businesses achieve their goals?

Advanced Manufacturing Consulting provides businesses with expert guidance and support to identify areas for improvement, implement innovative solutions, and drive operational excellence. By leveraging advanced technologies and best practices, businesses can enhance productivity, reduce costs, improve quality, and gain a competitive edge in the global marketplace.

What is the role of digital twins in Advanced Manufacturing Consulting?

Digital twins are virtual representations of manufacturing processes and equipment. Advanced Manufacturing Consultants utilize digital twins to monitor operations in real-time, predict potential issues, optimize performance, and make data-driven decisions. Digital twins enable businesses to improve efficiency, reduce downtime, and enhance overall manufacturing agility.

How can Advanced Manufacturing Consultants help businesses prepare for the future of manufacturing?

Advanced Manufacturing Consultants play a crucial role in helping businesses prepare for the future of manufacturing. They provide guidance on emerging technologies, such as artificial intelligence (AI), machine learning (ML), and additive manufacturing. By embracing these technologies and implementing innovative solutions, businesses can transform their operations, increase flexibility, and drive sustainable growth in the digital age.

What is the career outlook for Advanced Manufacturing Consultants?

The career outlook for Advanced Manufacturing Consultants is positive due to the increasing demand for manufacturing optimization and innovation. As businesses strive to improve efficiency, reduce costs, and remain competitive in the global market, the need for skilled professionals with expertise in advanced manufacturing technologies and best practices will continue to grow.

How can I become an Advanced Manufacturing Consultant?

To become an Advanced Manufacturing Consultant, a strong educational background in manufacturing engineering, industrial engineering, or a related field is recommended. Additionally, experience in manufacturing operations, process improvement, and advanced manufacturing technologies is highly valuable. Obtaining relevant certifications, such as Certified Lean Six Sigma Black Belt or Project Management Professional (PMP), can enhance your credibility and demonstrate your commitment to professional development.

What are the key trends shaping the future of Advanced Manufacturing Consulting?

Advanced Manufacturing Consulting is continuously evolving, driven by technological advancements and industry demands. Key trends shaping the future of the field include the adoption of artificial intelligence (AI) and machine learning (ML) for predictive analytics, the integration of digital twins for real-time monitoring and optimization, and the increasing focus on sustainability and circular economy principles in manufacturing.