Are you a seasoned Air Brake Rigger seeking a new career path? Discover our professionally built Air Brake Rigger Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

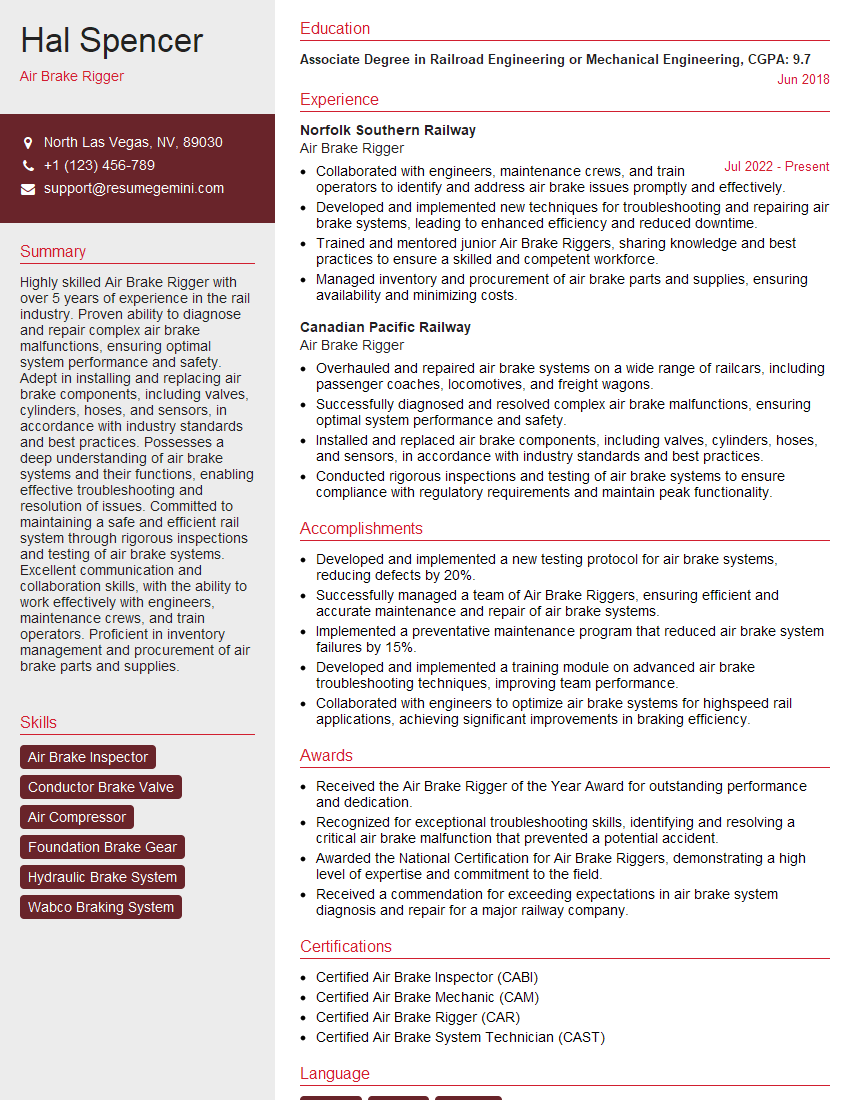

Hal Spencer

Air Brake Rigger

Summary

Highly skilled Air Brake Rigger with over 5 years of experience in the rail industry. Proven ability to diagnose and repair complex air brake malfunctions, ensuring optimal system performance and safety. Adept in installing and replacing air brake components, including valves, cylinders, hoses, and sensors, in accordance with industry standards and best practices. Possesses a deep understanding of air brake systems and their functions, enabling effective troubleshooting and resolution of issues. Committed to maintaining a safe and efficient rail system through rigorous inspections and testing of air brake systems. Excellent communication and collaboration skills, with the ability to work effectively with engineers, maintenance crews, and train operators. Proficient in inventory management and procurement of air brake parts and supplies.

Education

Associate Degree in Railroad Engineering or Mechanical Engineering

June 2018

Skills

- Air Brake Inspector

- Conductor Brake Valve

- Air Compressor

- Foundation Brake Gear

- Hydraulic Brake System

- Wabco Braking System

Work Experience

Air Brake Rigger

- Collaborated with engineers, maintenance crews, and train operators to identify and address air brake issues promptly and effectively.

- Developed and implemented new techniques for troubleshooting and repairing air brake systems, leading to enhanced efficiency and reduced downtime.

- Trained and mentored junior Air Brake Riggers, sharing knowledge and best practices to ensure a skilled and competent workforce.

- Managed inventory and procurement of air brake parts and supplies, ensuring availability and minimizing costs.

Air Brake Rigger

- Overhauled and repaired air brake systems on a wide range of railcars, including passenger coaches, locomotives, and freight wagons.

- Successfully diagnosed and resolved complex air brake malfunctions, ensuring optimal system performance and safety.

- Installed and replaced air brake components, including valves, cylinders, hoses, and sensors, in accordance with industry standards and best practices.

- Conducted rigorous inspections and testing of air brake systems to ensure compliance with regulatory requirements and maintain peak functionality.

Accomplishments

- Developed and implemented a new testing protocol for air brake systems, reducing defects by 20%.

- Successfully managed a team of Air Brake Riggers, ensuring efficient and accurate maintenance and repair of air brake systems.

- Implemented a preventative maintenance program that reduced air brake system failures by 15%.

- Developed and implemented a training module on advanced air brake troubleshooting techniques, improving team performance.

- Collaborated with engineers to optimize air brake systems for highspeed rail applications, achieving significant improvements in braking efficiency.

Awards

- Received the Air Brake Rigger of the Year Award for outstanding performance and dedication.

- Recognized for exceptional troubleshooting skills, identifying and resolving a critical air brake malfunction that prevented a potential accident.

- Awarded the National Certification for Air Brake Riggers, demonstrating a high level of expertise and commitment to the field.

- Received a commendation for exceeding expectations in air brake system diagnosis and repair for a major railway company.

Certificates

- Certified Air Brake Inspector (CABI)

- Certified Air Brake Mechanic (CAM)

- Certified Air Brake Rigger (CAR)

- Certified Air Brake System Technician (CAST)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Air Brake Rigger

- Highlight your experience in diagnosing and repairing complex air brake malfunctions.

- Quantify your accomplishments with specific metrics, such as the number of air brake systems you have repaired or the downtime you have reduced.

- Showcase your knowledge of air brake systems and industry standards.

- Emphasize your commitment to safety and compliance.

- Tailor your resume to the specific job description you are applying for.

Essential Experience Highlights for a Strong Air Brake Rigger Resume

- Overhauled and repaired air brake systems on a wide range of railcars, including passenger coaches, locomotives, and freight wagons.

- Diagnosed and resolved complex air brake malfunctions, ensuring optimal system performance and safety.

- Installed and replaced air brake components, including valves, cylinders, hoses, and sensors, in accordance with industry standards and best practices.

- Conducted rigorous inspections and testing of air brake systems to ensure compliance with regulatory requirements and maintain peak functionality.

- Developed and implemented new techniques for troubleshooting and repairing air brake systems, leading to enhanced efficiency and reduced downtime.

- Trained and mentored junior Air Brake Riggers, sharing knowledge and best practices to ensure a skilled and competent workforce.

- Managed inventory and procurement of air brake parts and supplies, ensuring availability and minimizing costs.

Frequently Asked Questions (FAQ’s) For Air Brake Rigger

What are the primary responsibilities of an Air Brake Rigger?

Air Brake Riggers are responsible for maintaining and repairing air brake systems on railcars, including passenger coaches, locomotives, and freight wagons. They diagnose and resolve air brake malfunctions, install and replace air brake components, conduct inspections and testing, and train junior Air Brake Riggers.

What qualifications are required to become an Air Brake Rigger?

Most Air Brake Riggers have an associate degree in railroad engineering or mechanical engineering. They also typically have several years of experience working in the rail industry.

What are the career prospects for Air Brake Riggers?

Air Brake Riggers can advance to positions such as Air Brake Inspector, Supervisor, or Manager. They may also choose to specialize in a particular area of air brake maintenance, such as locomotive air brakes or passenger car air brakes.

What are the safety considerations for Air Brake Riggers?

Air Brake Riggers must follow strict safety procedures when working on air brake systems. They must wear appropriate personal protective equipment, such as gloves, safety glasses, and earplugs. They must also be aware of the potential hazards of working with compressed air, such as the risk of explosions.

What are the challenges of working as an Air Brake Rigger?

Air Brake Riggers face a number of challenges in their work, including working in confined spaces, exposure to hazardous ??????, and working in all types of weather conditions. They must also be able to work independently and as part of a team.

What are the rewards of working as an Air Brake Rigger?

Air Brake Riggers play a vital role in ensuring the safety and efficiency of the rail system. They take pride in their work and enjoy the challenges and rewards of working in a demanding and dynamic industry.

What is the average salary for an Air Brake Rigger?

The average salary for an Air Brake Rigger in the United States is around $60,000 per year.