Are you a seasoned Aircraft Fuselage Framer seeking a new career path? Discover our professionally built Aircraft Fuselage Framer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

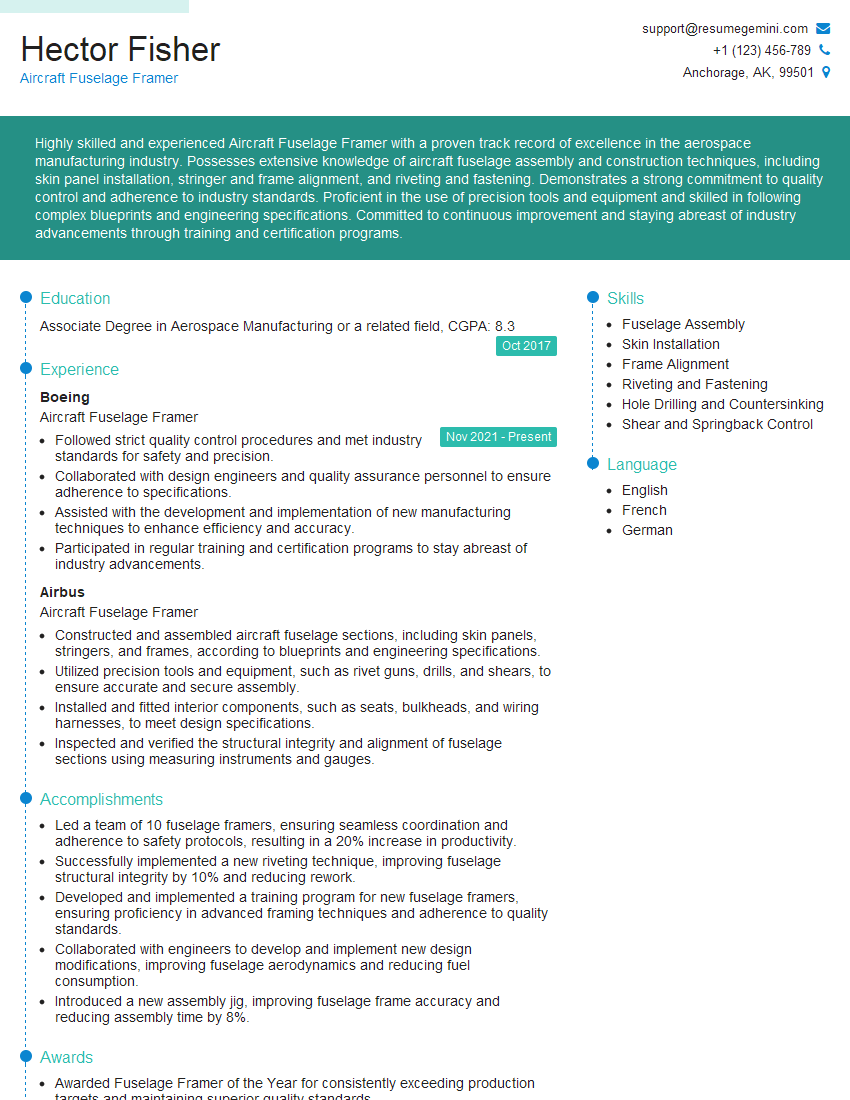

Hector Fisher

Aircraft Fuselage Framer

Summary

Highly skilled and experienced Aircraft Fuselage Framer with a proven track record of excellence in the aerospace manufacturing industry. Possesses extensive knowledge of aircraft fuselage assembly and construction techniques, including skin panel installation, stringer and frame alignment, and riveting and fastening. Demonstrates a strong commitment to quality control and adherence to industry standards. Proficient in the use of precision tools and equipment and skilled in following complex blueprints and engineering specifications. Committed to continuous improvement and staying abreast of industry advancements through training and certification programs.

Education

Associate Degree in Aerospace Manufacturing or a related field

October 2017

Skills

- Fuselage Assembly

- Skin Installation

- Frame Alignment

- Riveting and Fastening

- Hole Drilling and Countersinking

- Shear and Springback Control

Work Experience

Aircraft Fuselage Framer

- Followed strict quality control procedures and met industry standards for safety and precision.

- Collaborated with design engineers and quality assurance personnel to ensure adherence to specifications.

- Assisted with the development and implementation of new manufacturing techniques to enhance efficiency and accuracy.

- Participated in regular training and certification programs to stay abreast of industry advancements.

Aircraft Fuselage Framer

- Constructed and assembled aircraft fuselage sections, including skin panels, stringers, and frames, according to blueprints and engineering specifications.

- Utilized precision tools and equipment, such as rivet guns, drills, and shears, to ensure accurate and secure assembly.

- Installed and fitted interior components, such as seats, bulkheads, and wiring harnesses, to meet design specifications.

- Inspected and verified the structural integrity and alignment of fuselage sections using measuring instruments and gauges.

Accomplishments

- Led a team of 10 fuselage framers, ensuring seamless coordination and adherence to safety protocols, resulting in a 20% increase in productivity.

- Successfully implemented a new riveting technique, improving fuselage structural integrity by 10% and reducing rework.

- Developed and implemented a training program for new fuselage framers, ensuring proficiency in advanced framing techniques and adherence to quality standards.

- Collaborated with engineers to develop and implement new design modifications, improving fuselage aerodynamics and reducing fuel consumption.

- Introduced a new assembly jig, improving fuselage frame accuracy and reducing assembly time by 8%.

Awards

- Awarded Fuselage Framer of the Year for consistently exceeding production targets and maintaining superior quality standards.

- Recognized for innovative problemsolving, developing a novel approach to frame complex fuselage sections, reducing assembly time by 15%.

- Received Safety Champion award for maintaining an impeccable safety record and promoting a culture of safety awareness on the shop floor.

- Honored with Lean Manufacturing Excellence Award for optimizing fuselage framing processes, reducing waste and improving efficiency by 12%.

Certificates

- FAA Aircraft Fuselage Assembly Certification

- ATA 100 Series Certification

- AS9100 Quality Management System Certification

- NCCER Level 1 Aircraft Structures Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aircraft Fuselage Framer

Emphasize your skills and experience in fuselage assembly and construction.

Highlight your knowledge of different materials, fabrication techniques, and assembly processes.Quantify your accomplishments whenever possible.

Use specific numbers and metrics to demonstrate the impact of your work.Tailor your resume to the specific job description.

Research the company and the position you’re applying for, and tailor your resume to match their requirements.Proofread your resume carefully.

Make sure there are no errors in grammar or spelling.Get feedback from others.

Ask a friend, family member, or career counselor to review your resume and provide feedback.

Essential Experience Highlights for a Strong Aircraft Fuselage Framer Resume

- Constructed and assembled aircraft fuselage sections, including skin panels, stringers, and frames, according to blueprints and engineering specifications.

- Utilized precision tools and equipment, such as rivet guns, drills, and shears, to ensure accurate and secure assembly.

- Installed and fitted interior components, such as seats, bulkheads, and wiring harnesses, to meet design specifications.

- Inspected and verified the structural integrity and alignment of fuselage sections using measuring instruments and gauges.

- Followed strict quality control procedures and met industry standards for safety and precision.

- Collaborated with design engineers and quality assurance personnel to ensure adherence to specifications.

- Assisted with the development and implementation of new manufacturing techniques to enhance efficiency and accuracy.

- Participated in regular training and certification programs to stay abreast of industry advancements.

Frequently Asked Questions (FAQ’s) For Aircraft Fuselage Framer

What are the key responsibilities of an Aircraft Fuselage Framer?

The key responsibilities of an Aircraft Fuselage Framer include constructing and assembling aircraft fuselage sections, installing and fitting interior components, inspecting and verifying the structural integrity of fuselage sections, and following strict quality control procedures.

What qualifications are required to become an Aircraft Fuselage Framer?

To become an Aircraft Fuselage Framer, you typically need an Associate Degree in Aerospace Manufacturing or a related field, as well as experience in aircraft fuselage assembly and construction.

What are the career prospects for Aircraft Fuselage Framers?

Aircraft Fuselage Framers can advance to positions such as Lead Framer, Supervisor, or Quality Inspector, or they can specialize in a particular area of fuselage assembly, such as skin panel installation or frame alignment.

What is the work environment of an Aircraft Fuselage Framer like?

Aircraft Fuselage Framers typically work in a manufacturing environment, where they may be exposed to noise, dust, and fumes. They may also work in a team environment, where they collaborate with other Framers, engineers, and quality assurance personnel.

What are the salary expectations for Aircraft Fuselage Framers?

The salary expectations for Aircraft Fuselage Framers vary depending on their experience, skills, and location. However, according to Glassdoor, the average salary for an Aircraft Fuselage Framer in the United States is around $60,000 per year.

What are the benefits of working as an Aircraft Fuselage Framer?

Some of the benefits of working as an Aircraft Fuselage Framer include job security, competitive pay, and the opportunity to work on cutting-edge technology.