Are you a seasoned Aircraft Quality Control Inspector seeking a new career path? Discover our professionally built Aircraft Quality Control Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

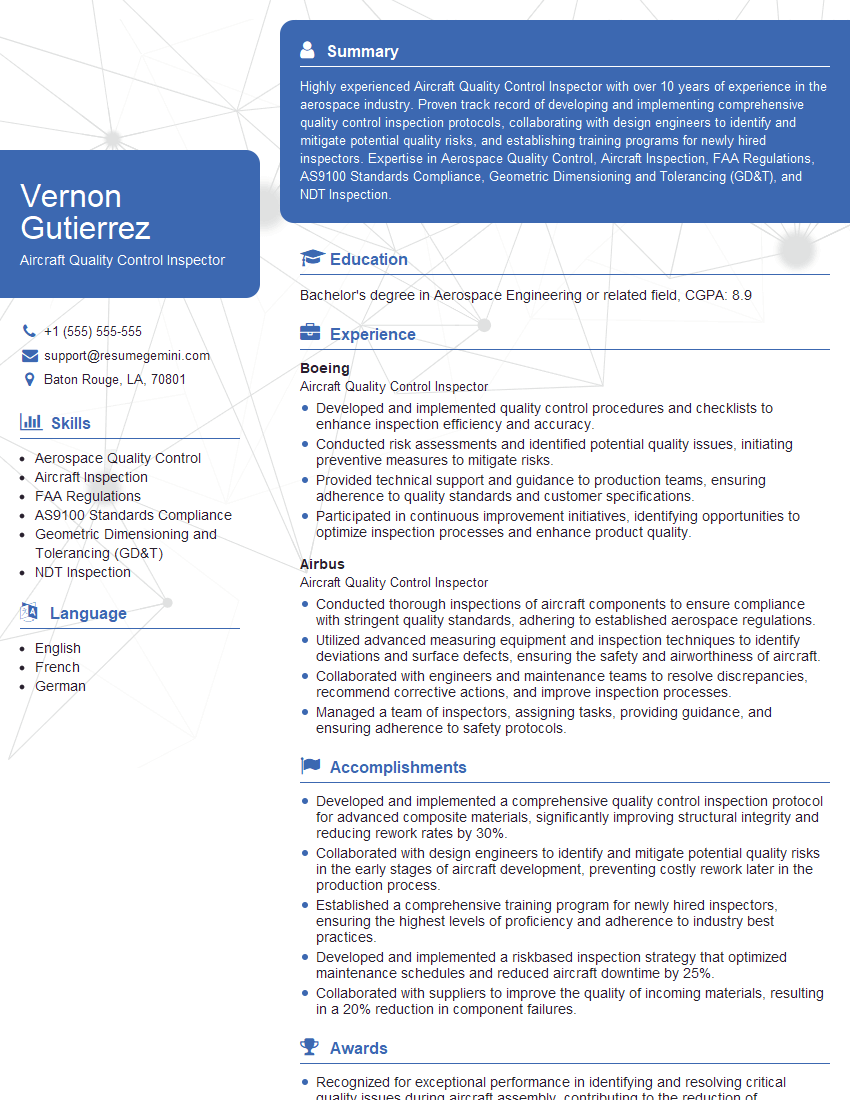

Vernon Gutierrez

Aircraft Quality Control Inspector

Summary

Highly experienced Aircraft Quality Control Inspector with over 10 years of experience in the aerospace industry. Proven track record of developing and implementing comprehensive quality control inspection protocols, collaborating with design engineers to identify and mitigate potential quality risks, and establishing training programs for newly hired inspectors. Expertise in Aerospace Quality Control, Aircraft Inspection, FAA Regulations, AS9100 Standards Compliance, Geometric Dimensioning and Tolerancing (GD&T), and NDT Inspection.

Education

Bachelor’s degree in Aerospace Engineering or related field

April 2018

Skills

- Aerospace Quality Control

- Aircraft Inspection

- FAA Regulations

- AS9100 Standards Compliance

- Geometric Dimensioning and Tolerancing (GD&T)

- NDT Inspection

Work Experience

Aircraft Quality Control Inspector

- Developed and implemented quality control procedures and checklists to enhance inspection efficiency and accuracy.

- Conducted risk assessments and identified potential quality issues, initiating preventive measures to mitigate risks.

- Provided technical support and guidance to production teams, ensuring adherence to quality standards and customer specifications.

- Participated in continuous improvement initiatives, identifying opportunities to optimize inspection processes and enhance product quality.

Aircraft Quality Control Inspector

- Conducted thorough inspections of aircraft components to ensure compliance with stringent quality standards, adhering to established aerospace regulations.

- Utilized advanced measuring equipment and inspection techniques to identify deviations and surface defects, ensuring the safety and airworthiness of aircraft.

- Collaborated with engineers and maintenance teams to resolve discrepancies, recommend corrective actions, and improve inspection processes.

- Managed a team of inspectors, assigning tasks, providing guidance, and ensuring adherence to safety protocols.

Accomplishments

- Developed and implemented a comprehensive quality control inspection protocol for advanced composite materials, significantly improving structural integrity and reducing rework rates by 30%.

- Collaborated with design engineers to identify and mitigate potential quality risks in the early stages of aircraft development, preventing costly rework later in the production process.

- Established a comprehensive training program for newly hired inspectors, ensuring the highest levels of proficiency and adherence to industry best practices.

- Developed and implemented a riskbased inspection strategy that optimized maintenance schedules and reduced aircraft downtime by 25%.

- Collaborated with suppliers to improve the quality of incoming materials, resulting in a 20% reduction in component failures.

Awards

- Recognized for exceptional performance in identifying and resolving critical quality issues during aircraft assembly, contributing to the reduction of maintenance costs by 15%.

- Awarded the Quality Excellence Award for consistently exceeding quality standards and achieving zero nonconformances in the inspection of critical aircraft components.

- Recognized for the development of innovative nondestructive testing techniques that enhanced the accuracy and efficiency of aircraft structural inspections.

- Received the Safety Champion Award for contributions to the implementation of enhanced safety measures in the aircraft maintenance facility.

Certificates

- ASQ Certified Quality Inspector

- Certified Aerospace Auditor

- FAA Aircraft Inspection Authorization

- Nadcap (National Aerospace and Defense Contractors Accreditation Program) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aircraft Quality Control Inspector

- Highlight your experience in Aerospace Quality Control and Aircraft Inspection.

- Showcase your knowledge of FAA Regulations and AS9100 Standards Compliance.

- Quantify your accomplishments using specific metrics whenever possible.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Aircraft Quality Control Inspector Resume

- Develop and implement quality control inspection protocols for aircraft components and assemblies.

- Inspect aircraft components and assemblies to ensure compliance with FAA regulations and industry standards.

- Identify and mitigate potential quality risks in the early stages of aircraft development.

- Train newly hired inspectors on quality control best practices and ensure adherence to industry standards.

- Collaborate with suppliers to improve the quality of incoming materials.

- Conduct risk-based inspections to optimize maintenance schedules and reduce aircraft downtime.

- Stay up-to-date on the latest quality control techniques and industry best practices.

Frequently Asked Questions (FAQ’s) For Aircraft Quality Control Inspector

What are the key skills required for an Aircraft Quality Control Inspector?

The key skills required for an Aircraft Quality Control Inspector include Aerospace Quality Control, Aircraft Inspection, FAA Regulations, AS9100 Standards Compliance, Geometric Dimensioning and Tolerancing (GD&T), and NDT Inspection.

What are the career prospects for an Aircraft Quality Control Inspector?

Aircraft Quality Control Inspectors with experience and expertise can advance to positions such as Quality Control Manager, Quality Assurance Manager, or even Director of Quality.

What are the challenges faced by an Aircraft Quality Control Inspector?

Aircraft Quality Control Inspectors face challenges such as ensuring the quality and safety of aircraft components and assemblies, staying up-to-date on the latest quality control techniques and industry best practices, and working in a fast-paced and demanding environment.

What is the work environment of an Aircraft Quality Control Inspector like?

Aircraft Quality Control Inspectors typically work in a manufacturing or maintenance facility, and may be required to work in different areas of the facility depending on the task at hand.

What are the salary expectations for an Aircraft Quality Control Inspector?

The salary expectations for an Aircraft Quality Control Inspector can vary depending on factors such as experience, location, and employer. According to Indeed, the average salary for an Aircraft Quality Control Inspector in the United States is around $60,000 per year.

What are the educational requirements for an Aircraft Quality Control Inspector?

Most Aircraft Quality Control Inspectors have a Bachelor’s degree in Aerospace Engineering or a related field.

What is the job outlook for an Aircraft Quality Control Inspector?

The job outlook for Aircraft Quality Control Inspectors is expected to be good over the next few years. This is due to the increasing demand for aircraft, which will lead to a greater need for quality control inspectors to ensure the safety and quality of aircraft components and assemblies.